Preparation of biochar by mixing sludge and red soil, preparation method and application

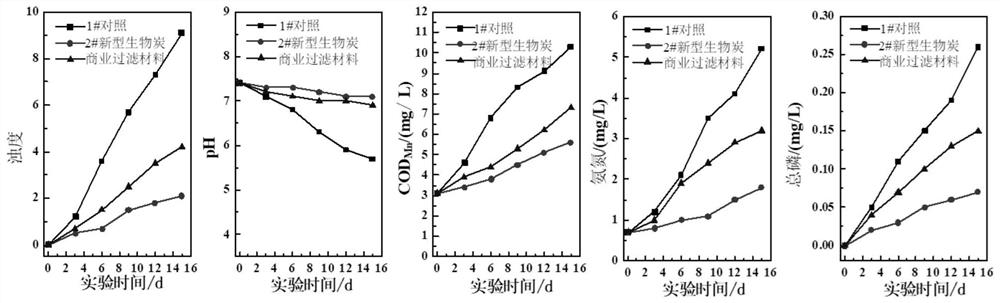

A biochar and red soil technology, applied in the fields of application, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of difficult sludge disposal, difficult cultivation of acidic soil, easy pollution of fish tank water quality, etc., to achieve extended replacement Effects of water cycling, increasing soil exchangeable base cation content, enhanced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

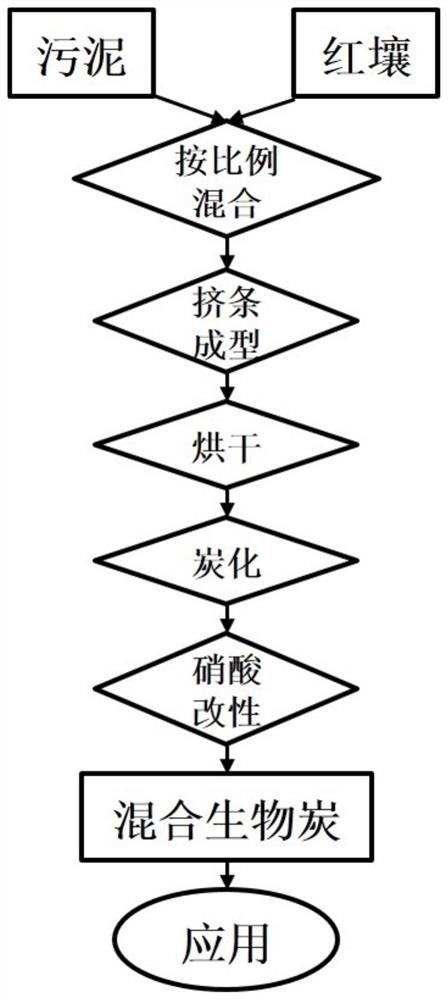

[0041] The preparation and application of new biochar such as figure 1 As shown, a new type of biochar prepared by mixing sludge and red soil is prepared by the following method:

[0042](1) Take the mechanically dewatered sludge with a moisture content of 75%, add red soil, and the red soil is the soil structure A0 layer, that is, the litter layer within 5cm from the ground surface, and the mass ratio of the mechanically dewatered sludge to the red soil is 1: 1. Move it into the oven for drying, the oven drying temperature is 60°C, and the drying time is 48 hours; and grind and sieve through a 200-mesh sieve; add the asparagus powder, and the dosage is 5% of the mass of the mixture; then mix with the nitric acid solution, the concentration of the nitric acid solution 6mol·L -1 , the quality of the nitric acid solution is 0.5% to 1% of the mass of the mixture; the mixed mud kneaded into strips has a diameter of 3mm and a length of 5mm;

[0043] (2) Dry the strip-shaped mixe...

Embodiment 2

[0056] A novel biochar prepared by mixing sludge and red soil is prepared by the following method:

[0057] (1) Take the mechanically dewatered sludge with a water content of 85%, add red soil, which is the A0 layer of soil structure, that is, the litter layer within 5cm from the ground surface, and the mass ratio of mechanically dewatered sludge to the red soil is 1: 1. Move it into the oven for drying, the oven drying temperature is 60°C, and the drying time is 84 hours; and grind and sieve through a 200-mesh sieve, add scallop powder, and the added mass is 5% of the mixture mass; then mix with nitric acid solution, the concentration of nitric acid solution 6mol·L -1 , the quality of the nitric acid solution is 0.5% to 1% of the mass of the mixture; the mixed mud kneaded into strips has a diameter of 3mm and a length of 5mm;

[0058] (2) Dry the strip-shaped mixed mud naturally at room temperature for 3 days; then put it into an oven for drying, the oven drying temperature ...

Embodiment 3

[0071] A novel biochar prepared by mixing sludge and red soil is prepared by the following method:

[0072] (1) Take the mechanically dewatered sludge with a moisture content of 80%, add red soil, which is the A0 layer of soil structure, that is, the litter layer within 5cm from the ground surface; the mass ratio of mechanically dewatered sludge to the red soil is 2: 1. Move it into an oven for drying, the oven drying temperature is 60°C, and the drying time is 72 hours; and grind and sieve through a 250-mesh sieve; add scallop powder, and the dosage is 4% of the mass of the mixture; then mix with nitric acid solution, the concentration of nitric acid solution 6mol·L -1 , the mass of nitric acid solution is 0.5-1% of the mass of the mixture; the diameter of the mixed mud kneaded into strips is 2 mm, and the length is 3 mm;

[0073] (2) Dry the strip-shaped mixed mud naturally at room temperature for 2 days, and then put it into an oven for drying. The oven drying temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com