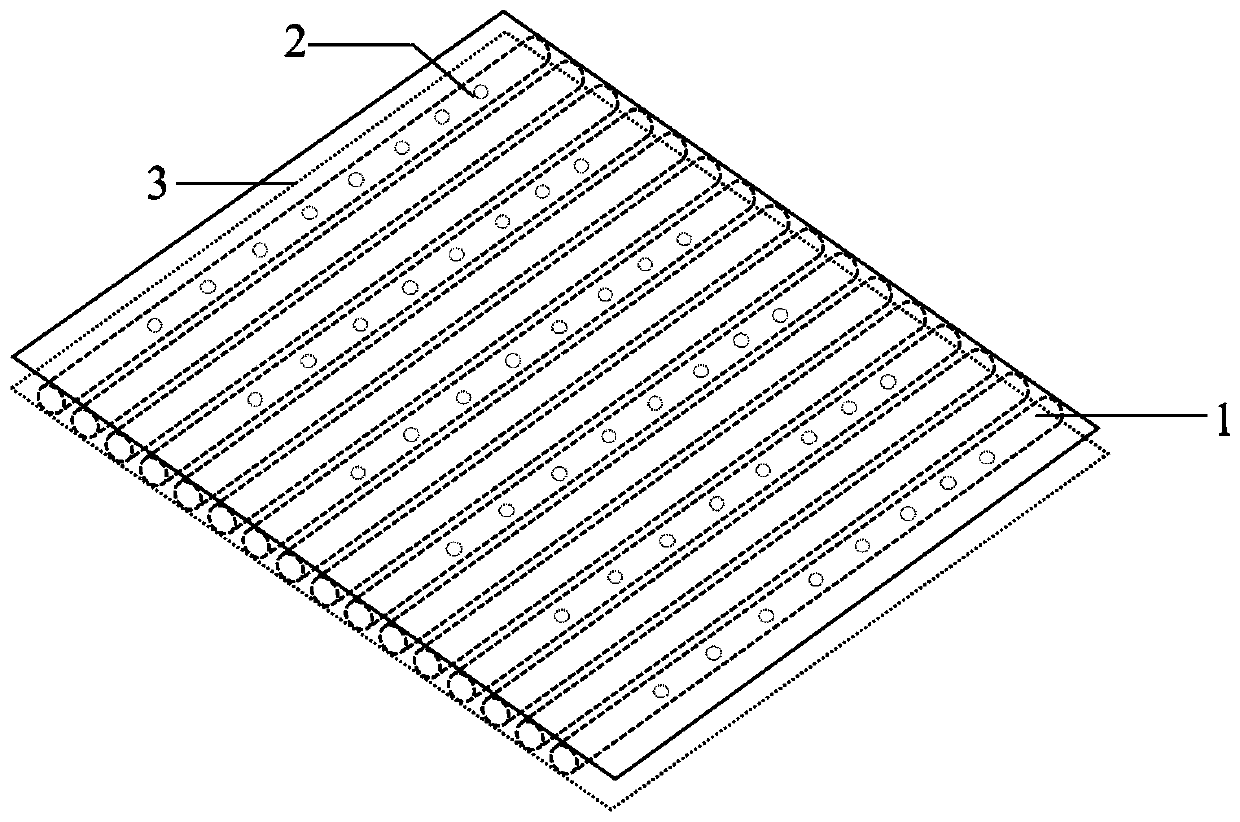

Novel ecological floating bed body

An ecological floating bed and bed technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of low buoyancy, poor stability, low strength, etc., and achieve good stability and safety, high gas barrier properties, long-term use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

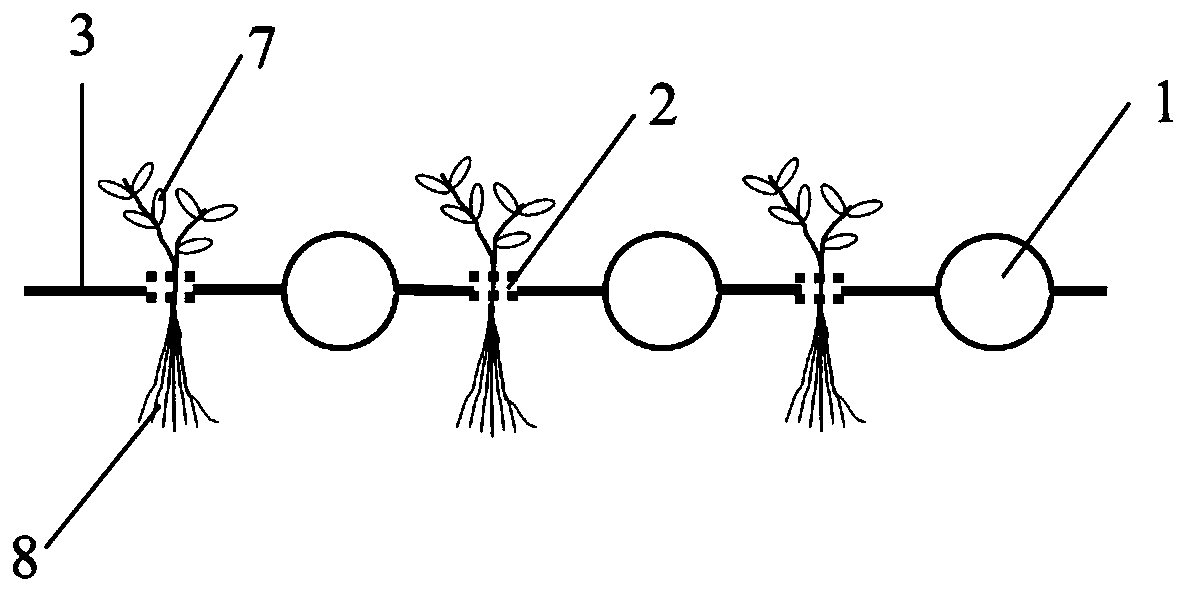

Method used

Image

Examples

Embodiment example 1

[0036] Implementation case 1: Cut part of the floating bed body and immerse it in salt water with a salinity of 35 to observe the performance of xanthan gum and the salt resistance of the material. After two months of soaking test, there is no degumming phenomenon, and it still has strong adhesion. Stretch force, the floating bed body can be used in saltwater waters such as offshore inner bays and lagoons.

Embodiment example 2

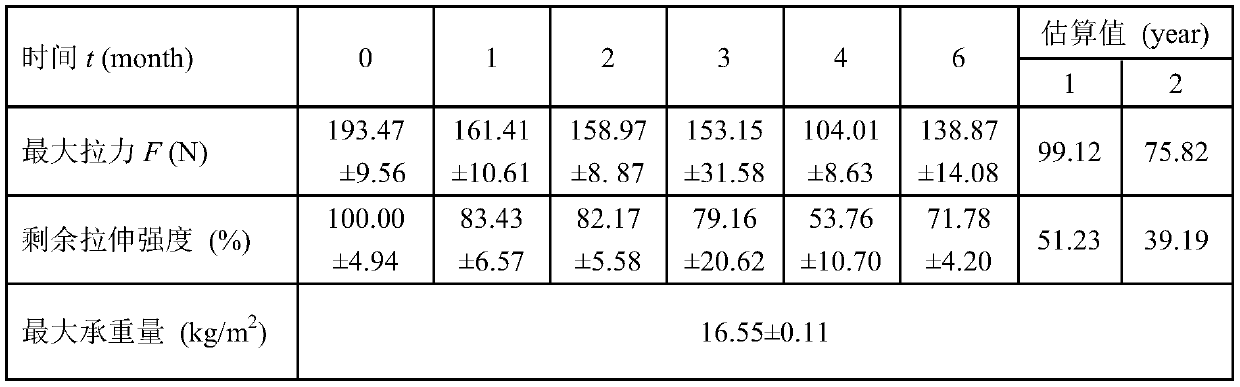

[0037] Implementation case 2: Tensile tests were carried out on the coated woven cloth laid on a floating bed carrier in different periods on a lake (GB / T1040.3-2006, the size of the tested sample is 15cm long × 1.5cm wide), and the new wetted cloth The film woven cloth is used as a comparison to evaluate the service life of the floating bed carrier. Table 1 shows the changes in the physical parameters of the film woven cloth;

[0038] Table 1

[0039]

[0040] From the results in Table 1, it can be known that:

[0041] 1. The film-coated woven fabric used in the present invention is in the natural aging process, and the force bearing capacity and deformation capacity slowly decline with the passage of time;

[0042] 2. After half a year of use, the integrity of the floating bed is good and there is no damage. According to the data measured in Table 1, the performance of the floating bed is good at present (1 and 2 years are estimated values), which is in line with the act...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap