A kind of elastomer used for rail transit under-rail block and preparation method thereof

A rail transit and elastomer technology, applied in the field of rail transit polymer materials, can solve the problems of shortened service cycle, short service life, large temperature influence, etc., and achieve the effect of improving overall performance, improving mechanical properties, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

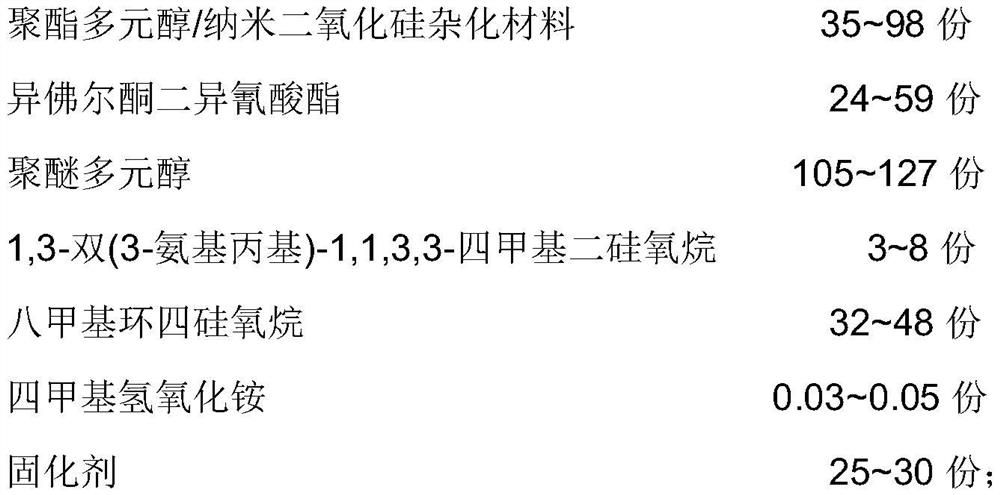

Image

Examples

Embodiment 1

[0057] I. Preparation of Polyester Polyol / Nano-Silica Hybrid Material

[0058] 8g N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane was added dropwise to a solution of 8.3g p-phenylenediisocyanate in toluene / ethyl acetate (100ml, volume ratio = 4:1); The reaction was mechanically stirred for 1.5 h at room temperature, then 141 g of polypropylene malonate and 0.45 g of stannous octoate were added, heated to 70-72 °C and stirred for 8 h at this temperature, and rotary-evaporated to remove the toluene / ethyl acetate solvent. Obtain prepolymer; Disperse 10g nano silica in 100g toluene, ultrasonic 30min, get nano silica dispersion; Next, take 15.2g prepolymer, mix with 12g described nano silica dispersion, 2g Water and 90 g of toluene were mixed, and the reaction was stirred at 80° C. for 3.5 hours, and the toluene and water were removed by rotary evaporation to prepare the polyester polyol / nano-silica hybrid material.

[0059] II. Preparation of Elastomers

[0060] Take 36g polye...

Embodiment 2

[0063] I. Preparation of Polyester Polyol / Nano-Silica Hybrid Material

[0064] 8.2g of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane was added dropwise to a solution of 9g of p-phenylenediisocyanate in toluene / ethyl acetate (110ml, volume ratio = 4:1); The reaction was mechanically stirred for 2h at room temperature, then 150g of polybutylene adipate and 0.6g of dibutyltin dilaurate were added, heated to 75~80°C, and the reaction was stirred at this temperature for 8.5h, and the toluene was removed by rotary evaporation. / ethyl acetate solvent to prepare a prepolymer; disperse 10g of nano-silica in 100g of toluene, and ultrasonically for 30min to obtain a nano-silica dispersion; then, take 23g of prepolymer, mix it with 16g of the nano-dioxide Silica dispersion, 4 g of water and 100 g of toluene were mixed, stirred and reacted at 85° C. for 3.5 h, and rotary evaporated to remove toluene and water to prepare the polyester polyol / nano silica hybrid material.

[0065] II. P...

Embodiment 3

[0069] I. Preparation of Polyester Polyol / Nano-Silica Hybrid Material

[0070] 8.6g of N-β-(aminoethyl)-γ-aminopropyltrimethoxysilane was added dropwise to a solution of 10.9g of p-phenylenediisocyanate in toluene / ethyl acetate (120ml, volume ratio=4:1); The reaction was mechanically stirred at room temperature for 2.5h, then 166.4g of polybutylene succinate and 0.72g of dibutyltin dilaurate were added, heated to 82~85°C, and the reaction was stirred at this temperature for 8h. Remove the toluene / ethyl acetate solvent to prepare a prepolymer; disperse 10 g of nano-silica in 100 g of toluene, and ultrasonicate for 30 min to obtain a nano-silica dispersion; The nano-silica dispersion liquid, 4 g of water and 115 g of toluene were mixed, stirred and reacted at 80° C. for 5 h, and rotary steamed to remove toluene and water to prepare the polyester polyol / nano-silica hybrid material.

[0071] II. Preparation of Elastomers

[0072] Take 56.3g of polyester polyol / nano silica hyb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com