Method for controlling growth of graphene nanocrystalline carbon film by adjusting irradiation density of ECR ions

A technology of ion irradiation and density control, applied in the direction of ion implantation plating, sputtering plating, metal material coating process, etc., can solve the problem of poor wear resistance, inconvenient contact surface application, low hardness of graphene nanocrystalline carbon film, etc. problem, to achieve the effect of good mechanical and tribological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

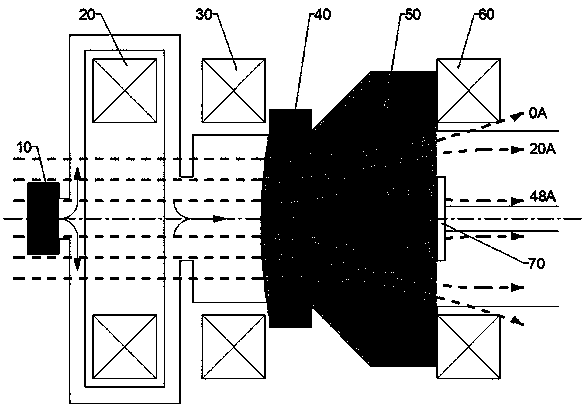

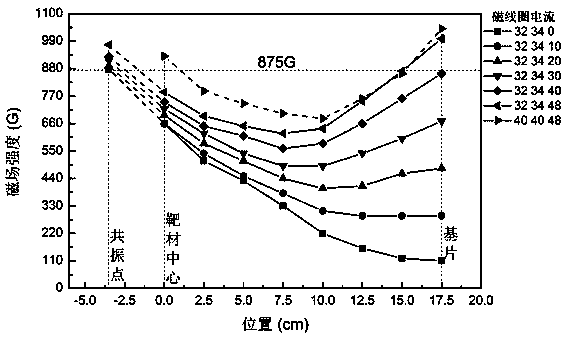

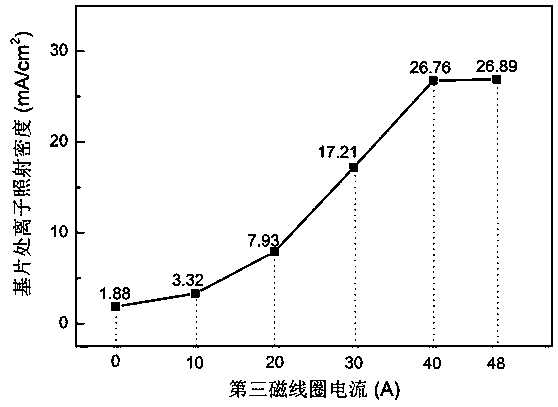

[0052] 1) Put a 25 mm×25 mm P-type Si substrate into a beaker filled with absolute ethanol, clean it with an ultrasonic instrument, wipe the surface of the substrate with a cleaning cloth dipped in acetone, and let it dry naturally Finally, fix it on the substrate holder with clips and load it into the film forming chamber; wait for the mechanical pump and molecular pump to pump the system vacuum to 7×10 -5 ~8×10 -5 Pa, and then into the argon to stabilize the pressure at 0.04 Pa; the first and second magnetic coils respectively apply 32 A and 34 A current to generate a magnetic field, and introduce microwaves with a microwave power of 700W to couple with the magnetic field to generate plasma, which is stable 10 minutes.

[0053] Before starting the deposition, apply a bias voltage of -50 V on the substrate, and use argon ions to bombard the surface of the substrate for cleaning for 2 to 4 minutes, and turn off the bias voltage after completion; then apply a bias voltage of ...

Embodiment 2

[0057] 1) Put a 25 mm×25 mm P-type Si substrate into a beaker filled with absolute ethanol, clean it with an ultrasonic instrument, wipe the surface of the substrate with a cleaning cloth dipped in acetone, and let it dry naturally Finally, fix it on the substrate holder with clips and load it into the film forming chamber; wait for the mechanical pump and molecular pump to pump the system vacuum to 7×10 -5 ~8×10 -5 At Pa, argon gas was introduced to stabilize the pressure at 0.04 Pa; currents of 32 A and 34 A were applied to the first and second magnetic coils respectively, and a current of 20 A was applied to the third magnetic coil to generate a magnetic field, and the microwave power introduced was A 700 W microwave is coupled with a magnetic field to generate plasma, which is stable for 10 minutes.

[0058] Before starting the deposition, apply a bias voltage of -50 V on the substrate, and use argon ions to bombard the surface of the substrate for cleaning for 2 to 4 mi...

Embodiment 3

[0062] 1) Put a 25 mm×25 mm P-type Si substrate into a beaker filled with absolute ethanol, clean it with an ultrasonic instrument, wipe the surface of the substrate with a cleaning cloth dipped in acetone, and let it dry naturally Finally, fix it on the substrate holder with clips and load it into the film forming chamber; wait for the mechanical pump and molecular pump to pump the system vacuum to 7×10 -5 ~8×10 -5 At Pa, the argon gas was introduced again to stabilize the pressure at 0.04 Pa; the first and second magnetic coils were respectively applied with 32 A and 34 A currents, and the third magnetic coil was applied with 48 A current to generate a magnetic field, and the microwave power introduced was A 700 W microwave is coupled with a magnetic field to generate plasma, which is stable for 10 minutes.

[0063] Before starting the deposition, apply a bias voltage of -50 V on the substrate, and use argon ions to bombard the surface of the substrate for cleaning for 2 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com