Core oil/water calibration method based on nuclear magnetic resonance transverse relaxation spectrum line

A technology of nuclear magnetic resonance and transverse relaxation, which is used in the analysis of nuclear magnetic resonance, material analysis through resonance, and measurement devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

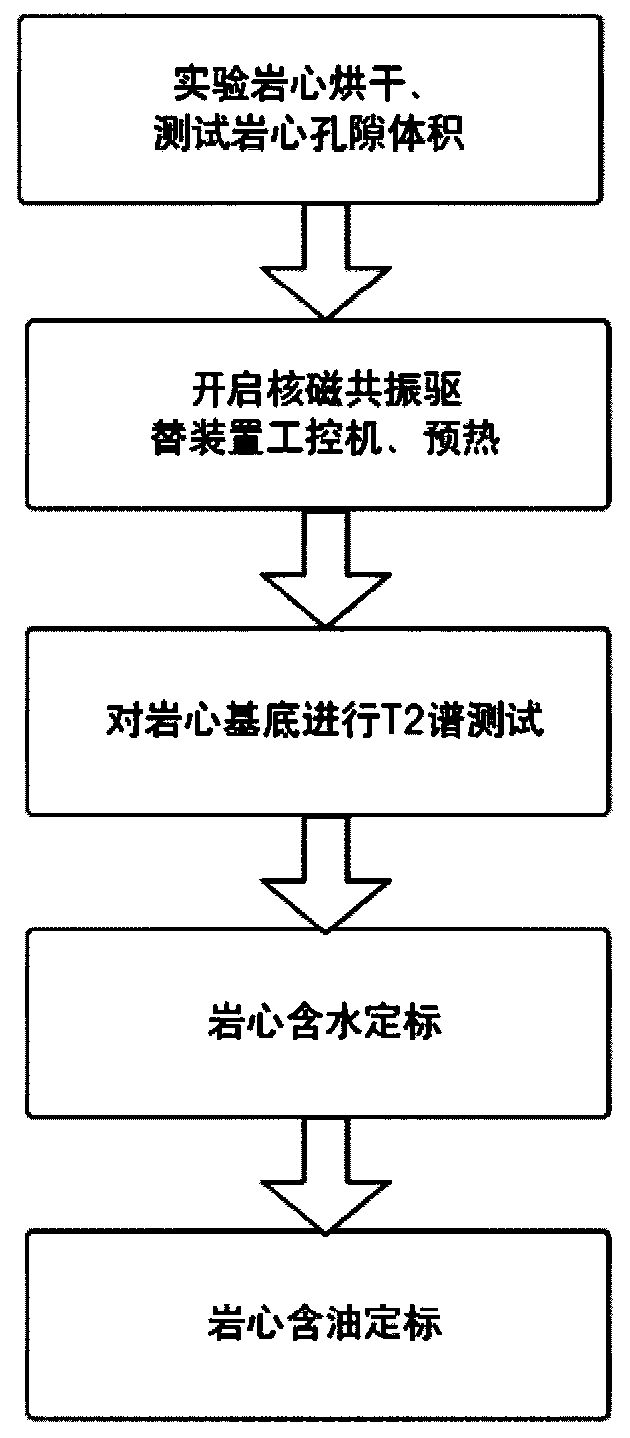

[0033] see Figure 1 to Figure 5 , this example is based on the core oil / water calibration method of nuclear magnetic resonance transverse relaxation lines. The corresponding relationship between the resonance T2 relaxation signal peak area is tested, that is, the calibration result of the oil / water mass or volume and the signal amplitude is obtained more accurately without affecting the experimental operation process, and the calibration is realized; the specific implementation steps as follows:

[0034] 1) Clean and dry the experimental core, and weigh the mass of the dry core in m R0 And use the gas porosity tester to test the core pore volume V 0 ;

[0035] 2) Turn on the industrial computer of the nuclear magnetic resonance displacement device and preheat;

[0036] 3) Put the dry core into the holder, load the appropriate ring pressure and adjust the parameters of the nuclear magnetic resonance instrument, and perform a T test on the core base. 2 Spectrum test, inver...

Embodiment 2

[0050] see Figure 1 to Figure 5 and Table 1 to Table 3.

[0051] Table 1 Core Physical Property Parameters

[0052]

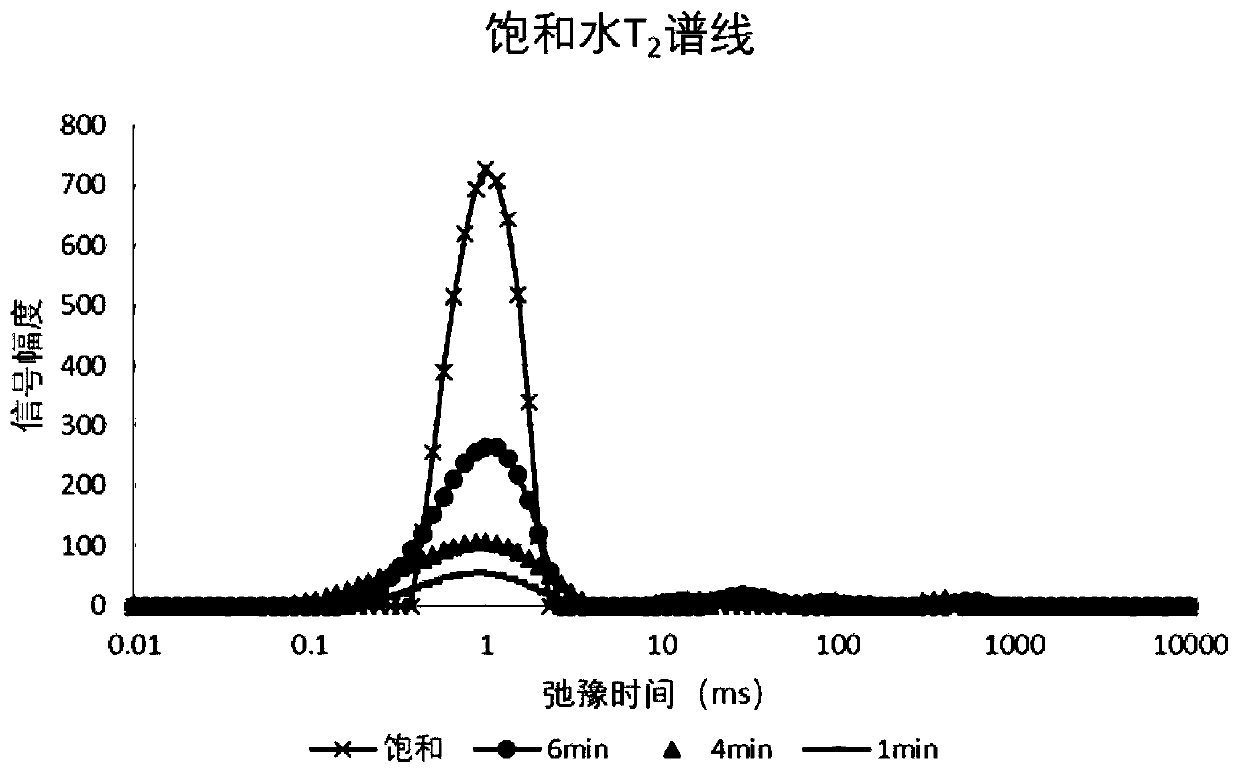

[0053] Table 2 NMR T2 spectral line peak area and saturation S 1 -14 The relationship between weighing and water quality in the process of drying core

[0054] Duration (min) weighing (g) Water content (g) Peak area 1.00 82.470 0.000 640.000 3.00 83.156 0.686 1356.600 4.00 83.510 1.040 1618.485 6.00 84.922 2.452 2764.481 saturation 95.604 13.134 9647.394

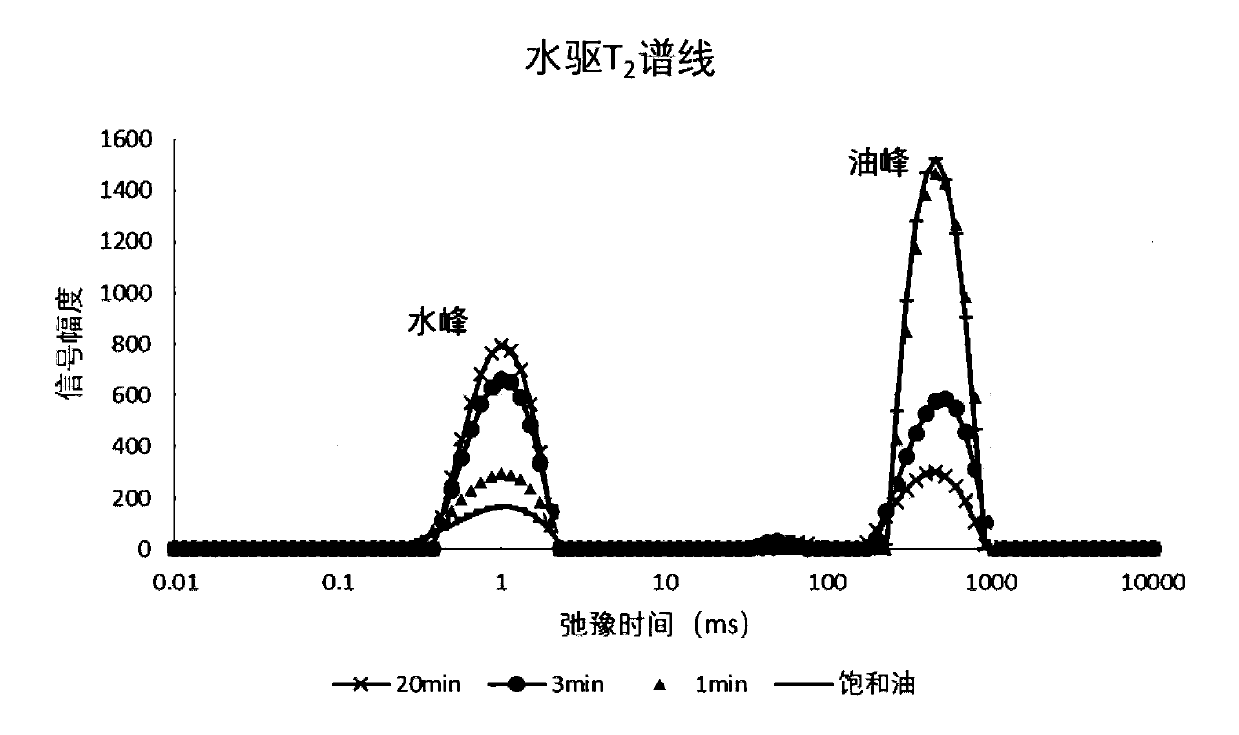

[0055] Table 3 The relationship between the oil peak area of the NMR T2 spectrum and the volume of diesel oil produced and the volume of oil in the displacement process

[0056]

[0057] This example is an oil / water calibration method for heterogeneous core water flooding and foam flooding.

[0058] 1. For the experimental core (code S 1 -14) wash and dry, weigh dry core quality m R0 =82.47g and utilize the gas porosity tester to test the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com