Comprehensive analysis device for combustion and fire extinguishing process of cup combustor

A cup burner and comprehensive analysis technology, which is applied in chemical analysis by combustion, material analysis by optical means, material analysis, etc., can solve the limitations that cannot meet the precise comprehensive analysis of combustion products, and cannot isolate the device from the surrounding environment , other parameters can not be studied, etc., to achieve the effect of avoiding damage and pollution, reducing impact, and high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

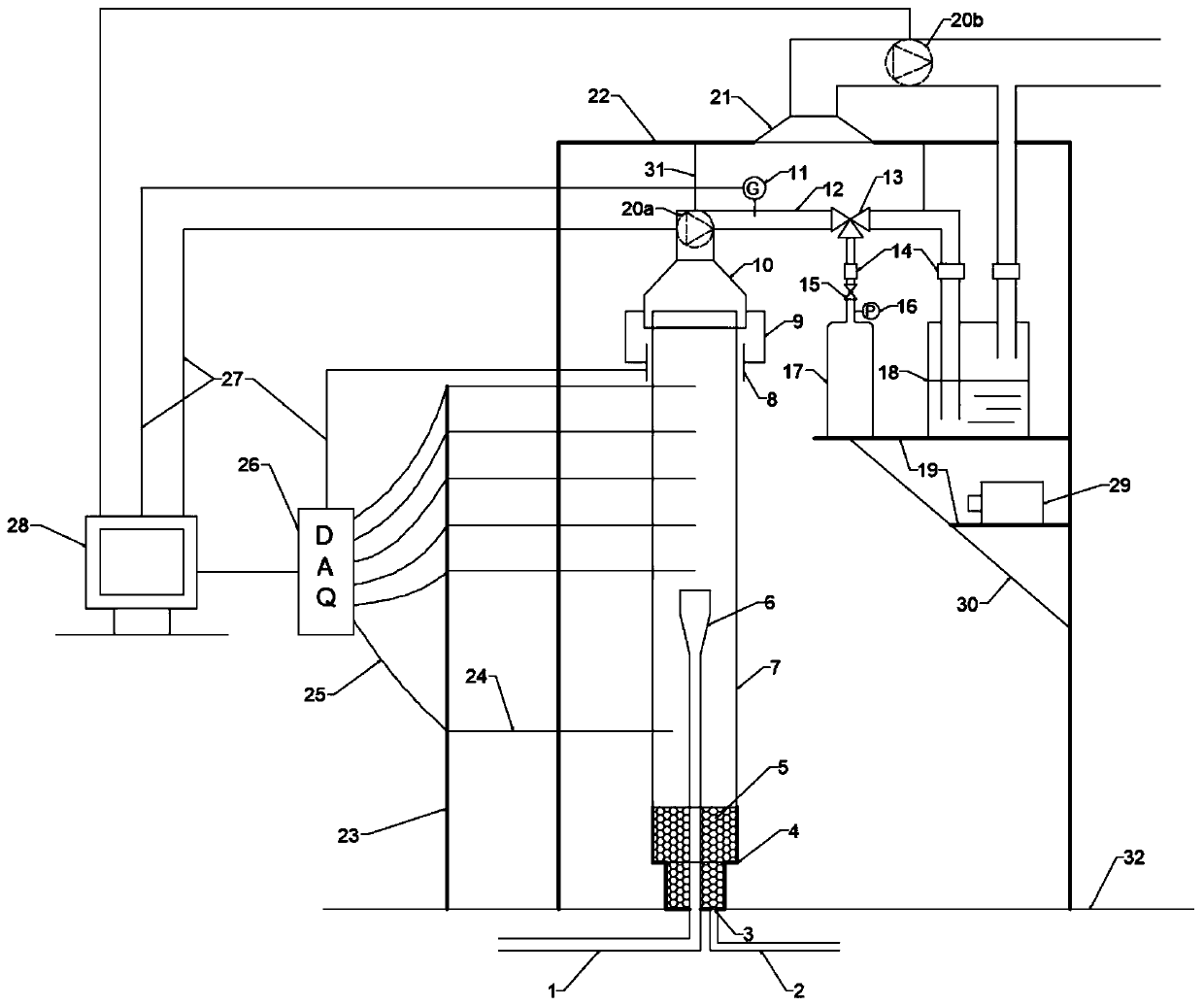

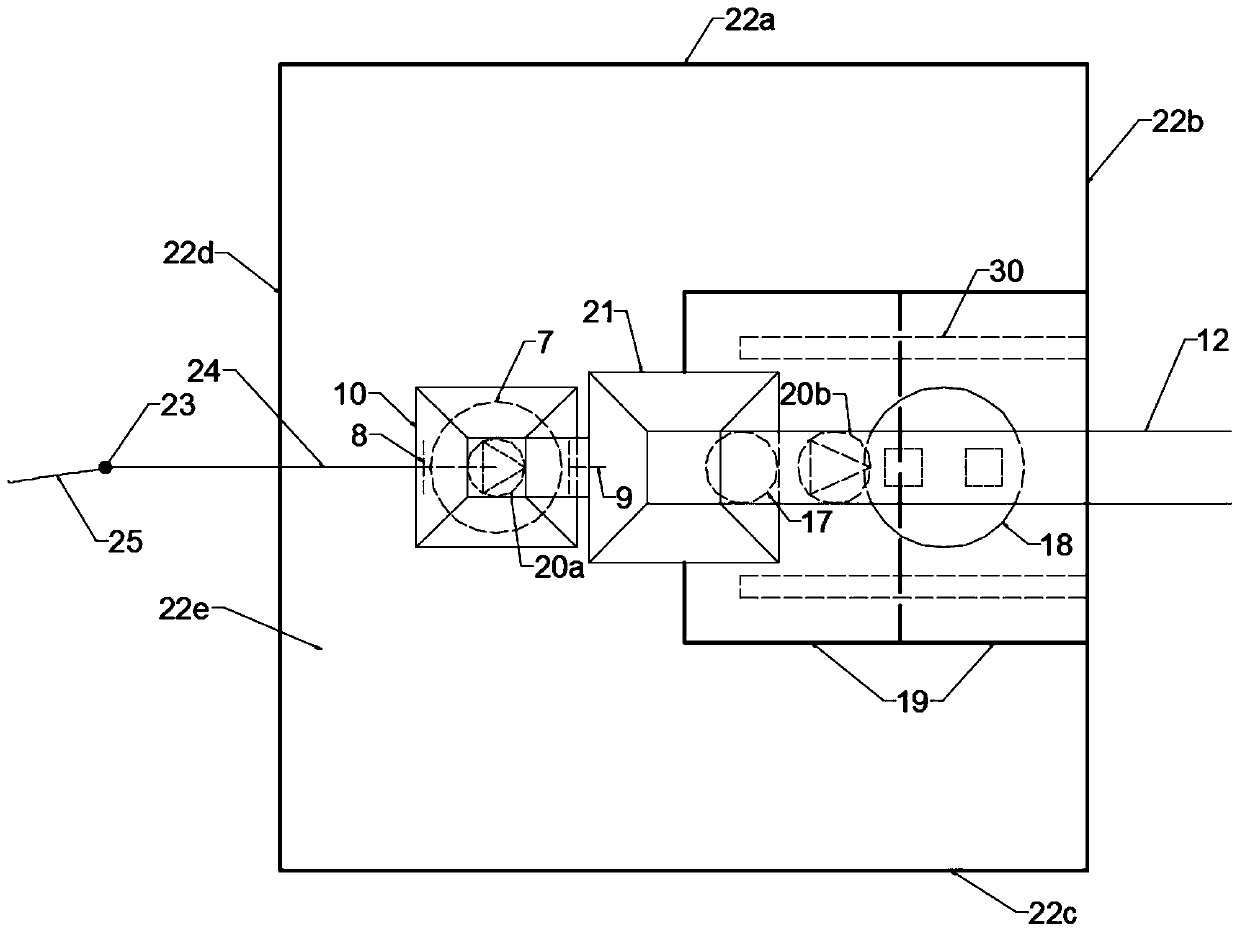

[0038] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0039] like figure 1 and figure 2 As shown, a comprehensive analysis device for the combustion and fire extinguishing process of the cup burner of the present invention includes a fuel supply pipeline 1, an air and fire extinguishing agent supply pipeline 2, an isolation net 3, a stainless steel base 4, and glass beads 5 , combustion cup 6, quartz cup cover 7, infrared gas detector 8, fixed bracket 9, gas collecting hood 10, flue gas analyzer 11, exhaust pipeline 12, three-way valve 13, two-way pipe 14, ball valve 15, Pressure gauge 16, high-pressure gas storage cylinder 17, gas collection cylinder 18, support platform 19, first fan 20a, first fan 20b, exhaust cover 21, quartz glass cover 22, thermocouple bracket 23, thermocouple 24, thermocouple Connection line 25, data acquisition device 26, transmission line 27, computer 28, high-speed came...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com