Steady-state flow test device and method for low-speed two-stroke marine diesel engine cylinder

A marine diesel engine and testing device technology, which is applied in the direction of measuring device, speed/acceleration/impact measurement, fluid velocity measurement, etc., can solve problems such as low measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

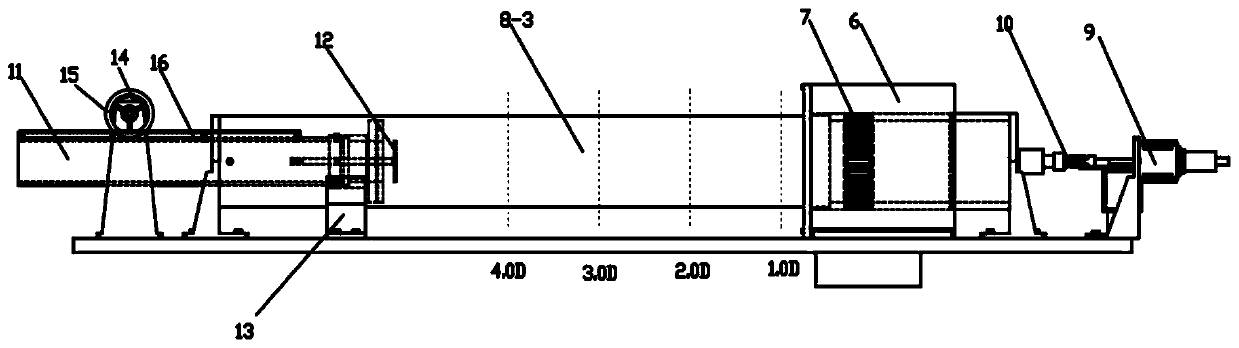

[0114] Single-cylinder machine scavenging flow test: close the valves on both sides of the scavenging box, and use the middle path to conduct a single-side air intake test. The bore is 170mm and the stroke is 850mm. The stroke is determined by the adjustment of the position of the vane anemometer assembly. Install the vane anemometer assembly, fix the vane at the stroke-to-bore ratio z / D=1.0, keep the opening of the scavenging port at 100%, and the opening of the exhaust valve at full open. Turn on the signal acquisition system, set the scavenging air pressure difference to 2000Pa, start the fan, read the eddy current speed obtained by the signal acquisition system after the air flow is stable, and then control the scavenging air pressure difference to 2000Pa, and adjust the blade by replacing the front and rear cylinder liners. The position of the anemometer assembly can be adjusted to achieve the adjustment of the stroke-to-bore ratio, so as to achieve the purpose of changing...

Embodiment 2

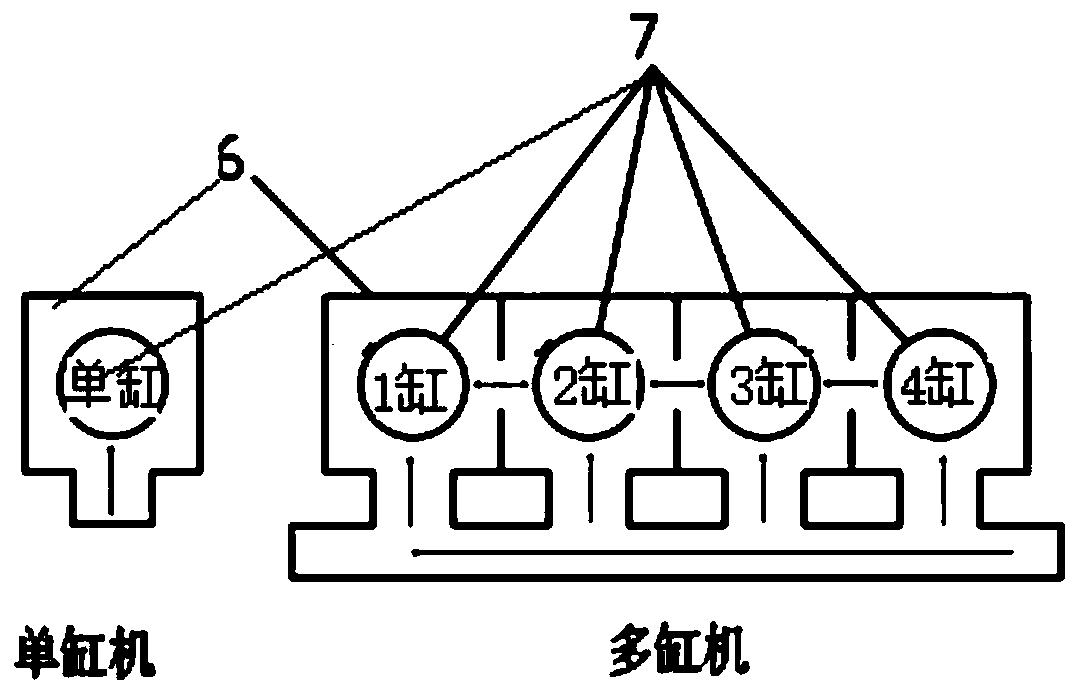

[0118] Multi-cylinder machine scavenging flow test. Such as figure 2 As shown, different from the intake mode of single-cylinder engine, the intake form of multi-cylinder engine is often double-side intake and three-side intake. The 1st and 4th cylinders in the multi-cylinder machine are double-sided air intakes. This device can open the left valve 17-1, close the right valve 17-2, and conversely open the right valve and close the left valve. Realize the same air intake method as the 1st and 4th cylinders. The second and third cylinders in the multi-cylinder engine have three-side air intake, which can be realized by opening the left and right valves at the same time. The test method of this part is the same as that of the above-mentioned single-cylinder engine.

Embodiment 3

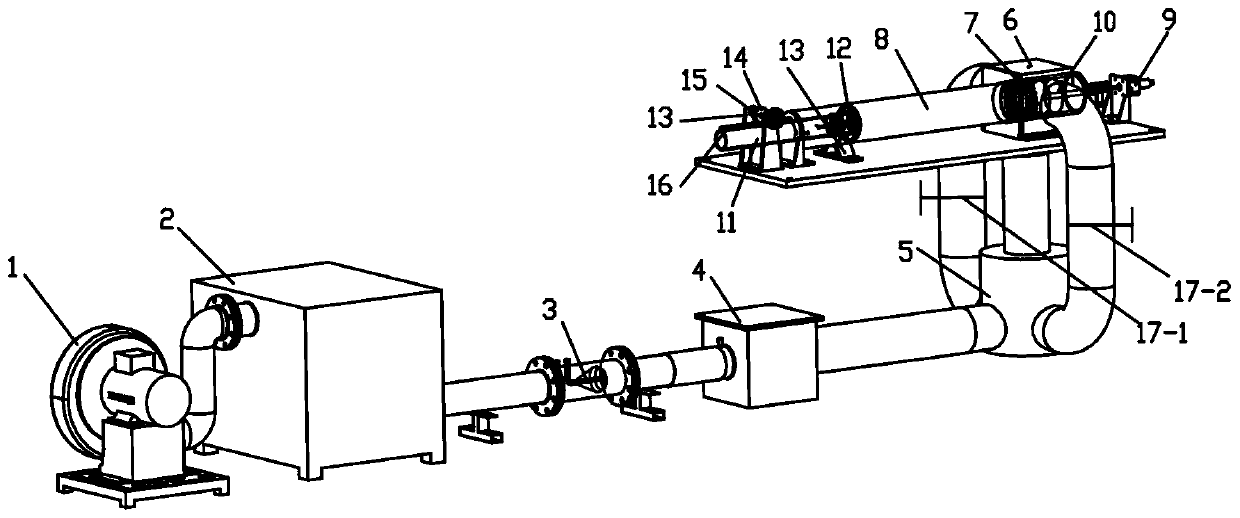

[0120] The air enters the voltage stabilizing box through the fan, and the fan and the stabilizing box are connected with hard bent pipes and flanges. After the pressure is stabilized, the air passes through the flow meter in the pipeline and enters the mixing box, and the tracer particles (used by the PIV instrument) are introduced into the outside of the tank, and the air and the tracer particles are fully mixed and then enter the pressure stabilization cylinder. The air flows through the scavenging port into the extended cylinder liner and is discharged through the exhaust valve and the exhaust pipe. The linear motor moves by controlling the piston.

[0121] When the 3D-PIV instrument system is used for measurement, the front and rear extended cylinder liners are replaced with a complete cylinder liner, and then the PIV instrument system is calibrated, referring to Figure 6 , Figure 7. Adjust the position of the CCD camera or the lens so that the shooting plane area is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com