Liquid baby milk suitable for 0-12-month old babies and preparation method of liquid baby milk

A baby milk, liquid technology, applied in the field of baby milk, can solve the problems of uncontrollable microorganisms, protein denaturation, precipitation and stability, unfavorable cleaning product labels, etc., and achieve the effect of reducing allergies, stable quality, and clean product labels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The invention provides an infant formula milk and a preparation method thereof. The dry matter content of the infant formula milk is 12.5wt.%, and the components contained in every 1000Kg of infant formula milk are as follows: 255.75Kg of raw cow milk hydrolyzate, hydrolyzed desalted milk Clear powder 61.50Kg, anhydrous butter 14.5Kg, vegetable oil 10.0Kg, lactose 9.5Kg, multivitamin 0.32Kg, multimineral 0.64Kg, choline 0.075Kg, taurine 0.065Kg, carrageenan 0.15Kg, citric acid 0.05Kg , the rest supplemented with water to 1000Kg.

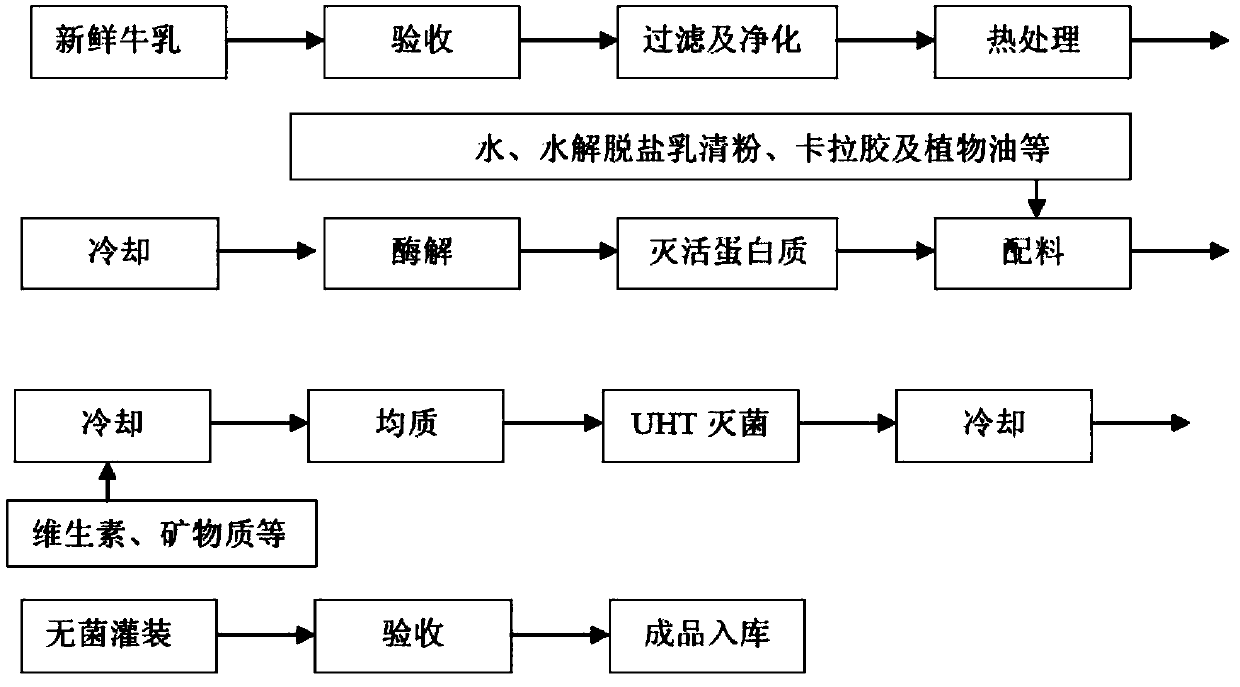

[0060] Such as figure 1 As shown in the flow chart, the preparation method of described infant formula milk comprises the following steps:

[0061] (1) After acceptance, filtration and purification of 255.75Kg of fresh raw milk, heat treatment at 80°C for 10 minutes to denature the protein, and cool the solution to 55°C;

[0062] (2) Add protease (by neutral protease F (Validase FP Concentrate, purchased from DSM Trading (Shanghai) Co., Ltd....

Embodiment 2

[0110] The invention provides an infant formula milk and a preparation method thereof. The dry matter content of the infant formula milk is 12.5wt.%, and the components contained in every 1000Kg of infant formula milk are as follows: 255.75Kg of raw cow milk hydrolyzate, hydrolyzed desalted milk Clear powder 61.50Kg, anhydrous butter 14.5Kg, vegetable oil 10.0Kg, lactose 9.5Kg, multivitamin 0.32Kg, multimineral 0.64Kg, choline 0.075Kg, taurine 0.065Kg, carrageenan 0.20Kg, citric acid 0.05Kg , the rest supplemented with water to 1000Kg.

[0111] Such as figure 1 As shown in the flow chart, the preparation method of described infant formula milk comprises the following steps:

[0112] (1) After acceptance, filtration and purification of 255.75Kg of fresh raw milk, heat treatment at 80°C for 10 minutes to denature the protein, and cool the solution to 55°C;

[0113] (2) Add protease Amano2SD (purchased from Amano Enzyme Co., Ltd.) to the above solution for enzymolysis, the amou...

Embodiment 3

[0121] The invention provides an infant formula milk and a preparation method thereof. The dry matter content of the infant formula milk is 12.5wt.%, and the components contained in every 1000Kg of infant formula milk are as follows: 255.75Kg of raw cow milk hydrolyzate, hydrolyzed desalted milk Clear powder 61.50Kg, anhydrous butter 14.5Kg, vegetable oil 10.0Kg, lactose 9.5Kg, multivitamin 0.32Kg, multimineral 0.64Kg, choline 0.075Kg, taurine 0.065Kg, carrageenan 0.10Kg, citric acid 0.05Kg , the rest supplemented with water to 1000Kg.

[0122] Such as figure 1 As shown in the flow chart, the preparation method of described infant formula milk comprises the following steps:

[0123] (1) After acceptance, filtration and purification of 255.75Kg of fresh raw milk, heat treatment at 80°C for 10 minutes to denature the protein, and cool the solution to 50°C;

[0124] (2) Add protease Amano C100 (purchased from Amano Enzyme Co., Ltd.) to the above solution for enzymolysis, the amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com