Control method for anti-oxidation of vitamin C injection

A control method and vitamin technology, which are applied in the preparation of test samples, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc. C instability and other problems, to achieve the effect of improving the process production efficiency, reducing the probability, and improving the qualified rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

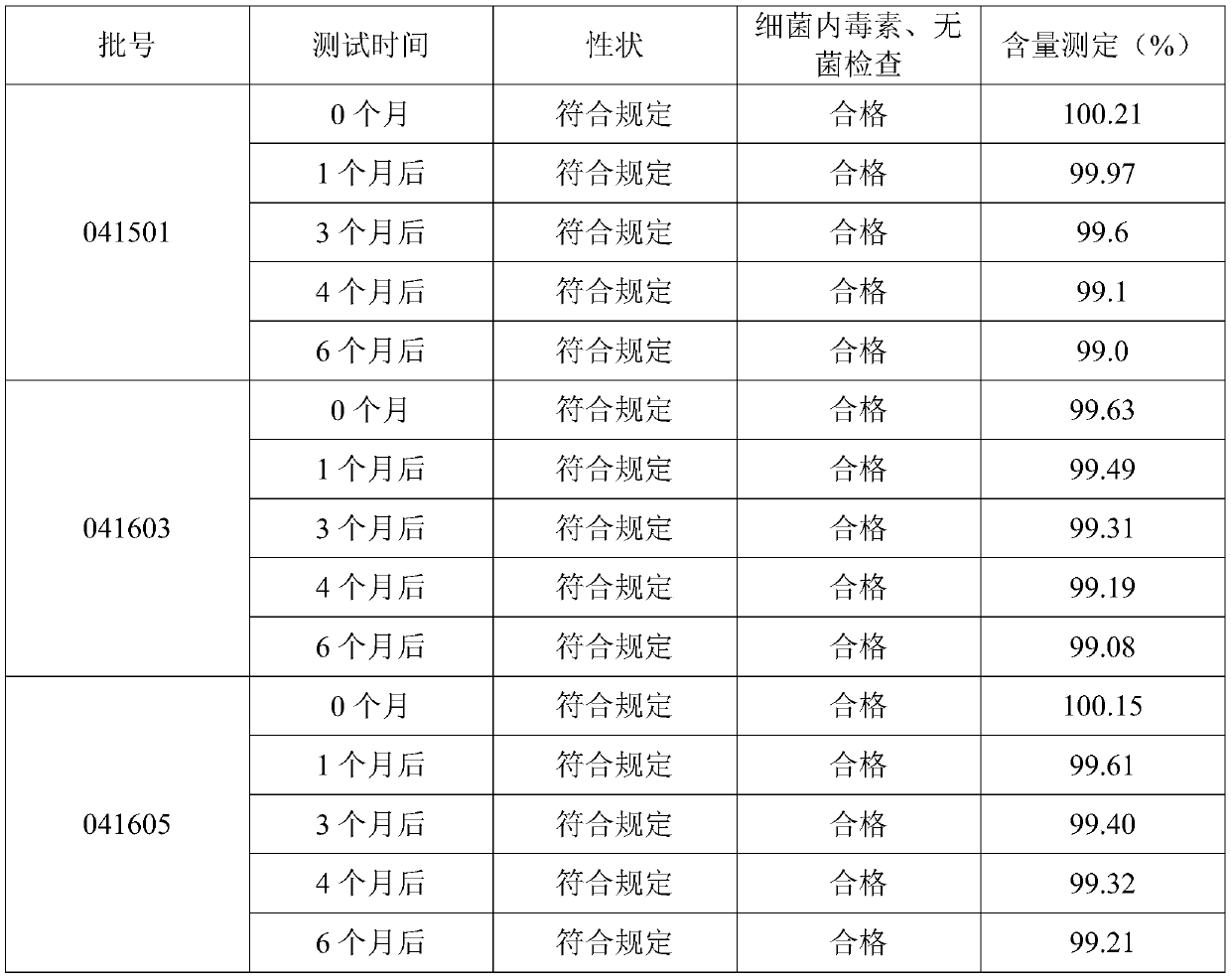

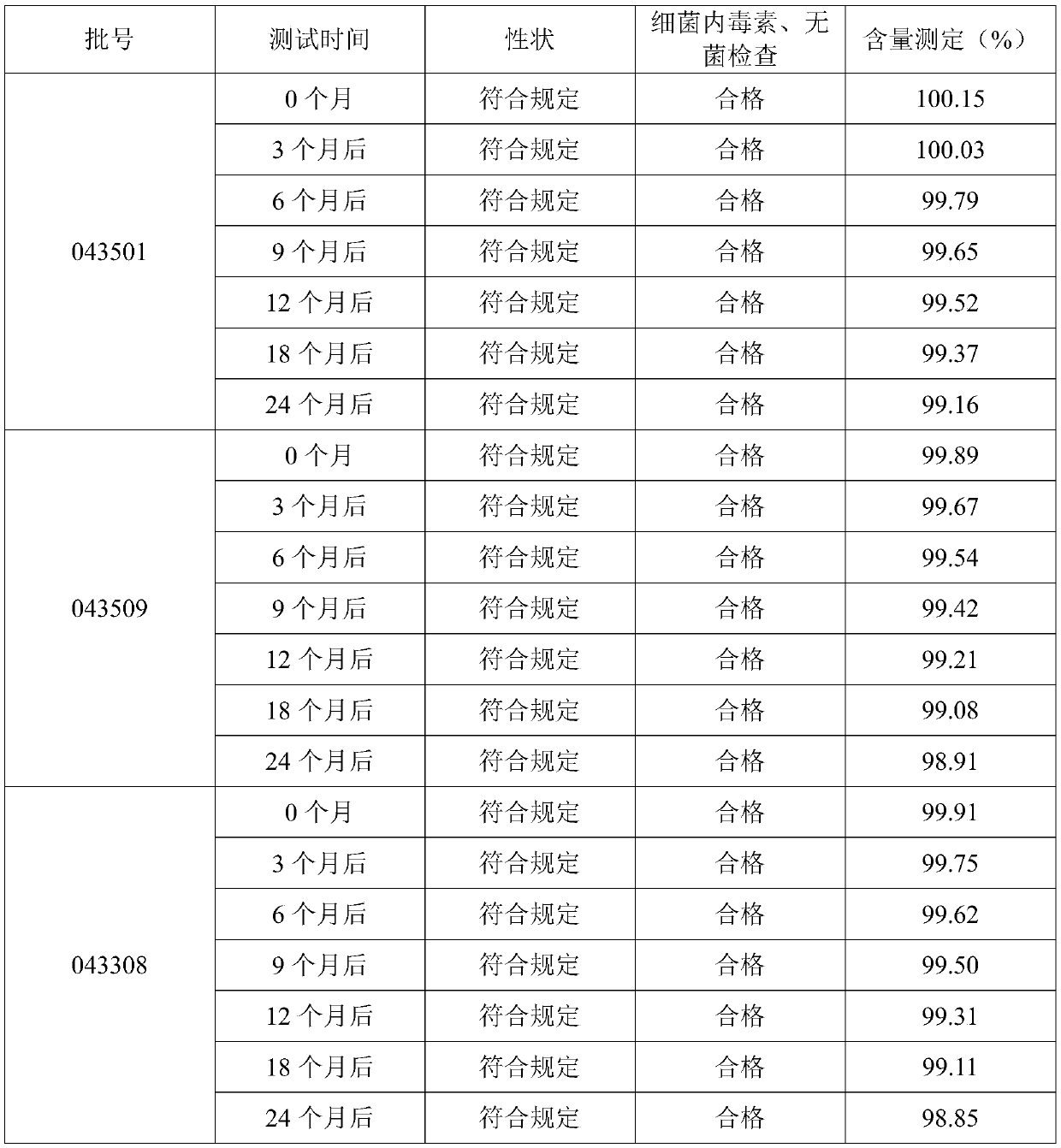

Examples

Embodiment 1

[0027] A method for controlling the anti-oxidation of vitamin C injection, the production process of vitamin C injection comprises the following steps: (1) quality control of raw material vitamin C and auxiliary materials, detection of furfural and Ca in raw material vitamin C 2+ content; detection of Ca in each excipient 2+ , Fe 3+ 、Cu 2+ and the content of sulfate; (2) the cleaning and drying of borosilicate ampoules: use circulating water, detergent, circulating water, clean compressed air, degraded water, clean compressed air, water for injection, and clean compressed air to carry out ampoules Cleaning, and then dry and sterilize the ampoule bottle; wherein, the filter element of the circulating water equipment is replaced every two weeks; (3) Preparation: includes the following steps: S1: Add water for injection of 2 / 3 of the preparation amount into the dispensing tank, The temperature was controlled at 32°C, and nitrogen gas with a purity of 99.99% was passed through t...

Embodiment 2

[0029] A method for controlling the anti-oxidation of vitamin C injection, the production process of vitamin C injection comprises the following steps: (1) quality control of raw material vitamin C and auxiliary materials, detection of furfural and Ca in raw material vitamin C 2+ content; detection of Ca in each excipient 2+ , Fe 3+ 、Cu 2+ and the content of sulfate; (2) the cleaning and drying of borosilicate ampoules: use circulating water, detergent, circulating water, clean compressed air, degraded water, clean compressed air, water for injection, and clean compressed air to carry out ampoules Cleaning, and then dry and sterilize the ampoule bottle; wherein, the filter element of the circulating water equipment is replaced every two weeks; (3) Preparation: includes the following steps: S1: Add water for injection of 2 / 3 of the preparation amount into the dispensing tank, The temperature was controlled at 32°C, and nitrogen gas with a purity of 99.99% was passed through t...

Embodiment 3

[0031] A method for controlling the anti-oxidation of vitamin C injection, the production process of vitamin C injection comprises the following steps: (1) quality control of raw material vitamin C and auxiliary materials, detection of furfural and Ca in raw material vitamin C 2+ content; detection of Ca in each excipient 2+ , Fe 3+ 、Cu 2+ and the content of sulfate; (2) the cleaning and drying of borosilicate ampoules: use circulating water, detergent, circulating water, clean compressed air, degraded water, clean compressed air, water for injection, and clean compressed air to carry out ampoules Cleaning, and then dry and sterilize the ampoule bottle; wherein, the filter element of the circulating water equipment is replaced every two weeks; (3) Preparation: includes the following steps: S1: Add water for injection of 2 / 3 of the preparation amount into the dispensing tank, The temperature was controlled at 32°C, and nitrogen gas with a purity of 99.99% was passed through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com