A control method for the enhanced pretreatment of vanadium precipitation wastewater by resin adsorption separation

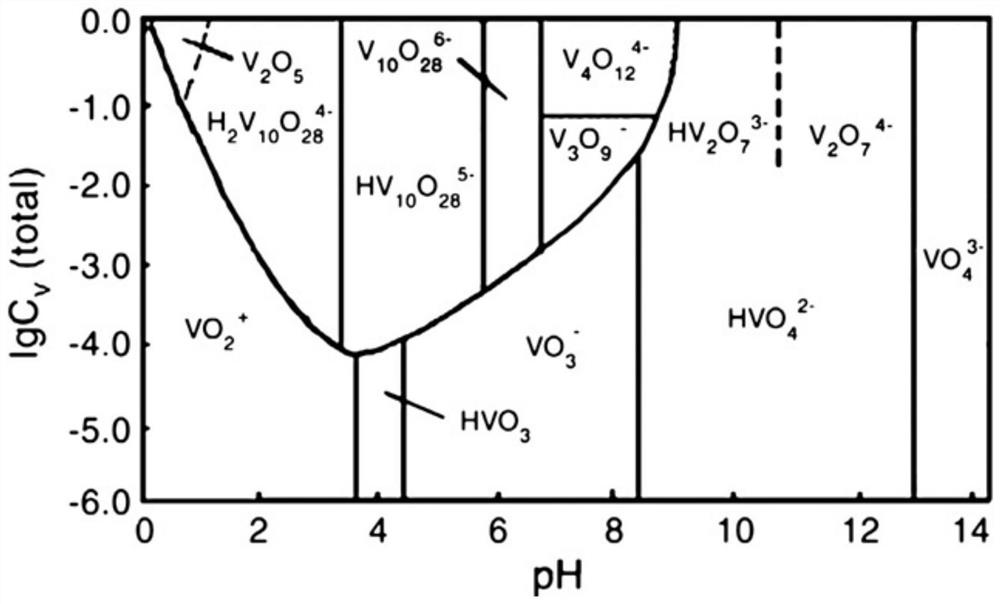

A technology for resin adsorption and vanadium precipitation wastewater, which is applied in water treatment parameter control, adsorption water/sewage treatment, water/sewage treatment, etc. It can solve the problems of inability to carry out precise control and difficulty in effectively separating vanadium and chromium elements, so as to improve resin Separation efficiency, avoiding the reduction of processing efficiency, and the effect of high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

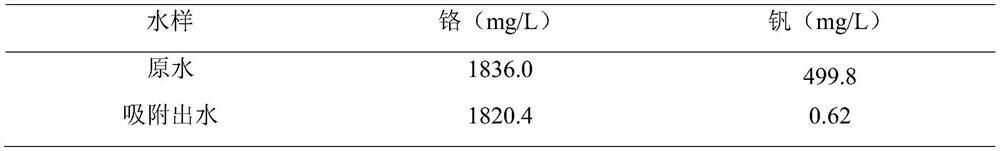

Embodiment 1

[0044] The operation steps of the vanadium precipitation wastewater that the present embodiment is aimed at are as follows:

[0045] (1) Take 1L of vanadium precipitation wastewater, the initial pH of the wastewater is 1.78, and the initial oxidation-reduction potential ORP 1 is 684.2mv;

[0046] (2) Carry out reduction treatment, add reducing agent sodium thiosulfate in the raw water, the reduction potential ORP after the reduction reaction is complete 2 Set to 600mv, the dosage M1 of the reducing agent can be calculated from the reducing agent calculation formula, namely:

[0047] M1=A*ln(ORP 1 -ORP 2 )-B Formula 1;

[0048] A=3±0.3; B=5.5±0.5;

[0049] In this example, A is 2.7, and B is 6. From this, it can be calculated that the dosage of the reducing agent is 6.0 g / L, and the reaction time after adding the reducing agent is 60 minutes;

[0050] (3) Adjust the base of the water sample after reduction, adjust the pH to 3 with sodium hydroxide, and stabilize the oxida...

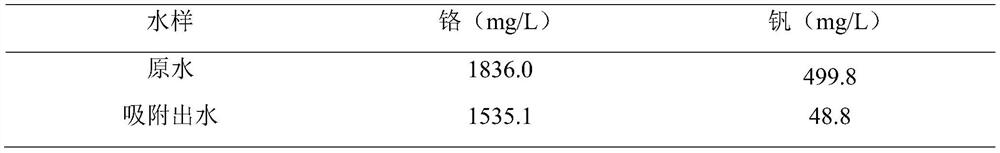

Embodiment 2

[0059] The operation steps of the vanadium precipitation wastewater that the present embodiment is aimed at are as follows:

[0060] (1) Take 1L of vanadium precipitation wastewater, the initial pH of the wastewater is 1.78, and the initial oxidation-reduction potential ORP 1 is 684.2mv;

[0061] (2) Carry out reduction treatment, add the reducing agent sodium thiosulfate to the raw water, and the target oxidation-reduction potential ORP after the reduction reaction is complete 2 The value is 620mv, and the dosage M1 of reducing agent can be calculated from the formula of reducing agent, namely:

[0062] M1=A*ln(ORP 1 -ORP 2 )-B Formula 1;

[0063] A=3±0.3; B=5.5±0.5;

[0064] In this embodiment, A takes 3.3, and B takes 5. From this, it can be calculated that the dosage of the reducing agent is 8.7g / L. Adding the reducing agent sodium thiosulfate can be added in stages, and the first stage is 5g, and the reaction The time is 30 minutes; the second level is added with 3....

Embodiment 3

[0074] The operation steps of the vanadium precipitation wastewater that the present embodiment is aimed at are as follows:

[0075] (1) Take 1L of vanadium precipitation wastewater, the initial pH of the wastewater is 1.81, and the initial oxidation-reduction potential ORP 1 is 691.2mv;

[0076] (2) Carry out reduction treatment, add the reducing agent sodium metabisulfite to the raw water, and the target oxidation-reduction potential ORP after the reduction reaction is complete 2 The value is 550mv, and the dosage M1 of the reducing agent can be calculated from the reducing agent calculation formula, namely:

[0077] M1=A*ln(ORP 1 -ORP 2 )-B Formula 1;

[0078] A=3±0.3; B=5.5±0.5;

[0079] In this example, A is taken as 3, and B is taken as 5.5. From this, it can be calculated that the dosage of the reducing agent is 9.35g / L. Adding the reducing agent sodium thiosulfate can be added in stages, and the first stage is 6g. The reaction time is 30min; the second stage is 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com