Drainage type asphalt concrete abrasion layer and construction method thereof

An asphalt concrete and wear layer technology, applied in building components, building thermal insulation materials, buildings, etc., can solve the problems of low road strength and stability, slow construction speed, and scattered aggregates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

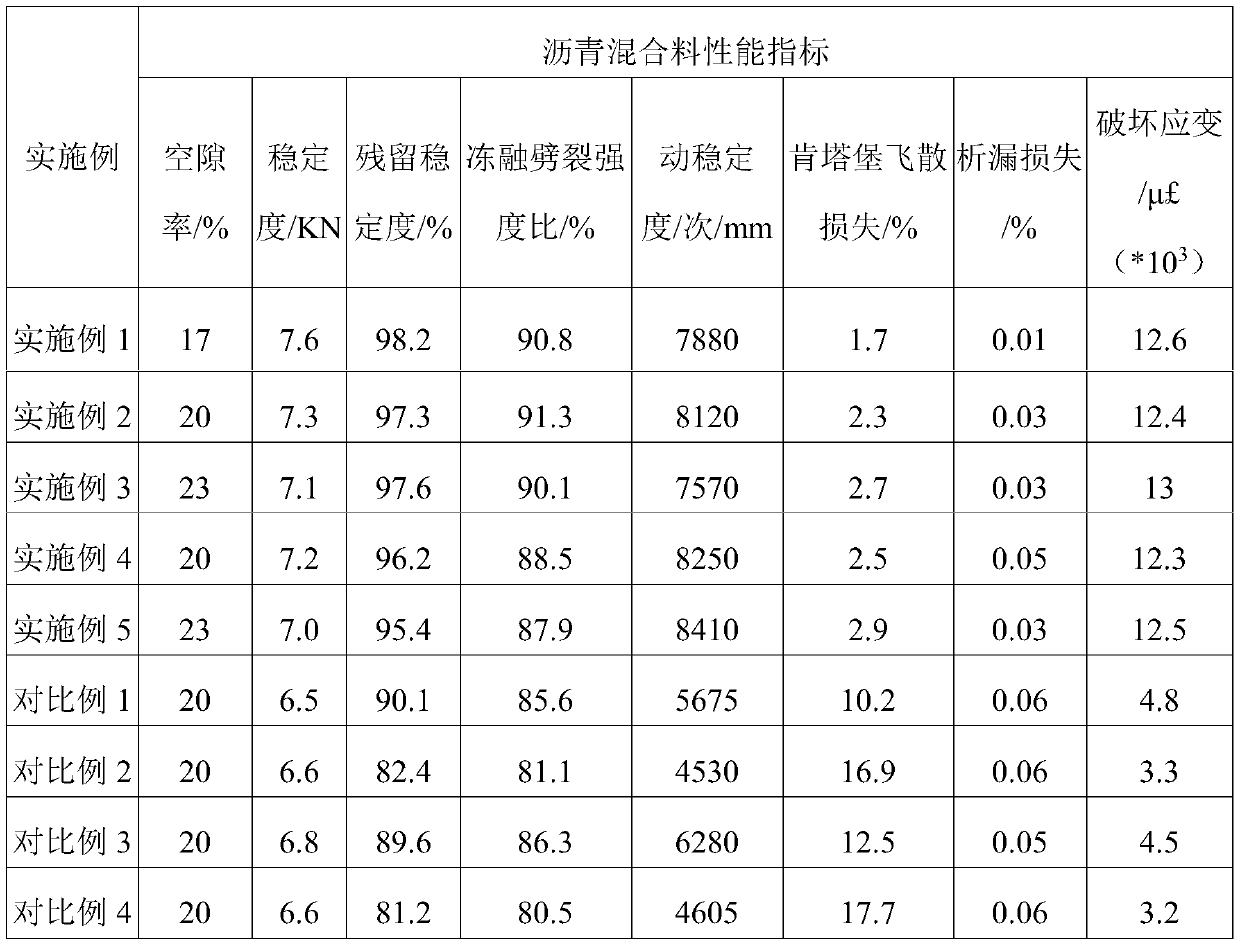

Examples

Embodiment 1-5

[0077] The raw material components of Examples 1-5 are all as described in Table 1.

[0078] Table 1

[0079] Raw material components Example 1 Example 2 Example 3 Example 4 Example 5 Super high viscosity modified asphalt bitumen ratio / % 5.1 5 4.9 4.9 4.8 Aggregate / % 95 97 97 97 97 Mineral powder / % 5 3 3 3 3 Porosity% 17 20 23 20 23 Asphalt concrete layer thickness / mm 15 15 15 20 20

[0080] Wherein, the amount of ultra-high-viscosity modified asphalt, the percentages in aggregate and mineral powder are all percentages by mass.

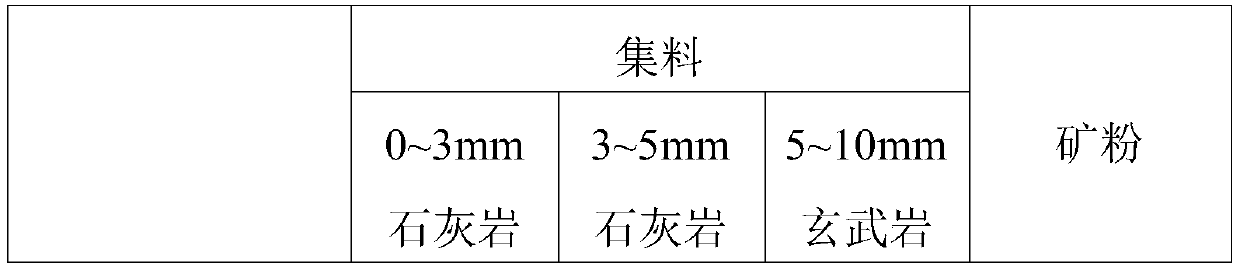

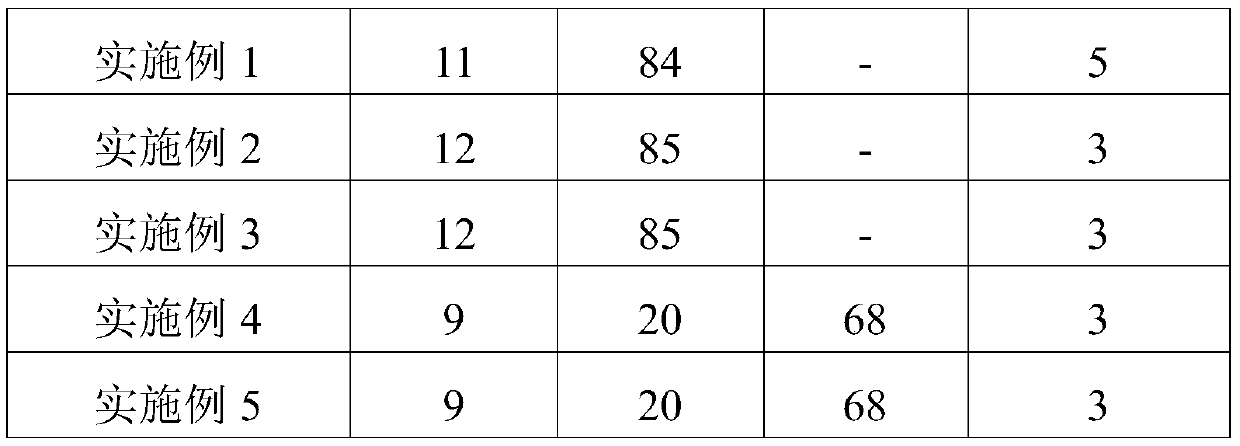

[0081] The above-mentioned aggregates are all composed of crushed stones. The specific types and proportions of the crushed stones are shown in Table 2. The above-mentioned mineral powders are specifically limestone mineral powders.

[0082] Table 2

[0083]

[0084]

[0085] (The above data refers to the mass ratio. For example, the first line of the data refers to: in E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com