Method for preparing high-performance conductive silicone rubber through in-situ ring-opening polymerization of cyclosiloxane

A technology of ring-opening polymerization and cyclosiloxane, which is applied in the field of preparing high-performance conductive silicone rubber nanocomposites through vulcanization molding, which can solve the problems of complex process, poor tear resistance, and low elongation of conductive silicone rubber. Achieve the effects of uniform distribution, excellent elasticity and tensile properties, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

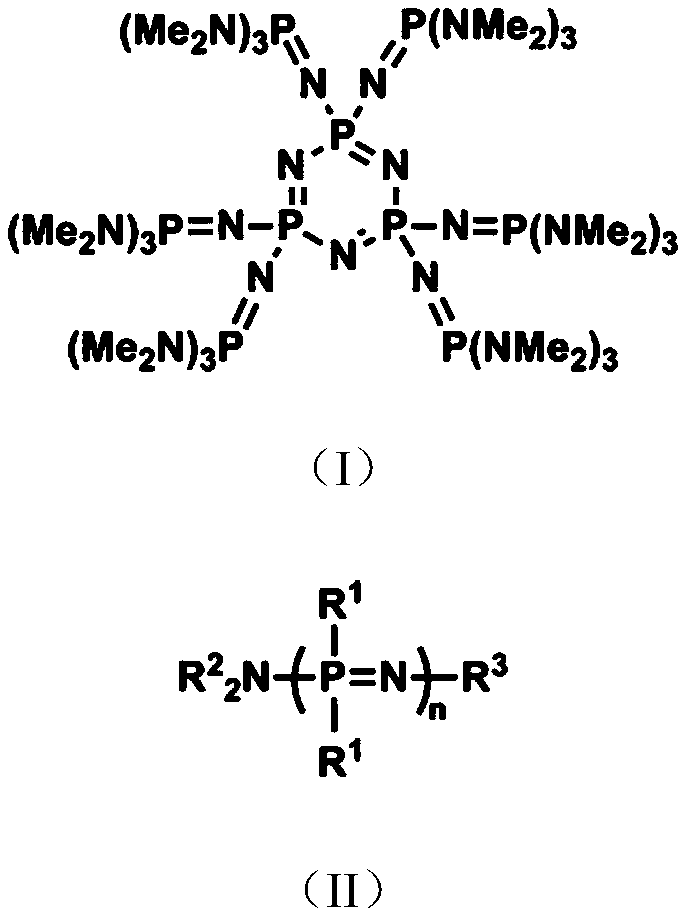

Method used

Image

Examples

Embodiment 1

[0046] Under the protection of nitrogen, under the condition of 100°C, 100 parts by mass of octamethylcyclotetrasiloxane (50.0g) and 1 part of tetramethyltetravinylcyclotetrasiloxane (0.5g) were mixed uniformly, and added 5 parts of carbon fiber particles (2.5g), 10 parts of fumed silica (5.0g), 1 part of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane (0.5g), maintain high speed Stir, add 0.01 parts by mass of phosphazene alkali catalyst toluene solution (catalyst concentration 0.05M), the polymerization reaction starts, the viscosity of the reaction system increases rapidly, and the condition of 100 ° C is kept for 20 minutes to obtain uniform in-situ doped carbon fiber particles. Polysiloxane premix material.

[0047] The above in-situ doped polysiloxane premixed material was added into the mold, and vulcanized for 10 minutes at a vulcanization temperature of 170° C. to obtain an in-situ doped carbon fiber silicone rubber nanocomposite material. The silicone rubber had a volume...

Embodiment 2

[0049] Under the protection of nitrogen, under the condition of 100°C, 100 parts by mass of octamethylcyclotetrasiloxane (50.0g) and 1 part of tetramethyltetravinylcyclotetrasiloxane (0.5g) were mixed uniformly, and added 10 parts of conductive carbon black nanoparticles (5.0g), 20 parts of fumed silica (10.0g), 1 part of 2,5-dimethyl-2,5-di-tert-butylperoxyhexane (0.5g) , maintain high-speed stirring, add 0.01 parts by mass of phosphazene alkali catalyst toluene solution (catalyst concentration 0.05M), the polymerization reaction starts, the viscosity of the reaction system increases rapidly, and continue to maintain the condition of 100 ° C for 20 minutes to obtain uniform in-situ doping Polysiloxane premix of conductive carbon black particles.

[0050] The above in-situ doped polysiloxane premixed material was added into a mold, and vulcanized for 10 minutes at a vulcanization temperature of 170° C. to obtain an in-situ doped conductive carbon black silicone rubber nanocomp...

Embodiment 3

[0052] Under nitrogen protection, at 60°C, 100 parts by mass of octamethylcyclotetrasiloxane (50.0g), 1 part of tetramethylcyclotetrasiloxane (0.5g) and 1 part of tetramethylcyclotetrasiloxane Tetravinylcyclotetrasiloxane (0.5g) is mixed evenly, adds 10 parts of conductive carbon black nanoparticles (5.0g), 20 parts of fumed silica (10.0g), 0.01 part of Karstedt catalyst (platinum-siloxane Complex, Pt content 5000ppm) (5.0mg), maintain high-speed stirring, add the phosphazene base catalyst toluene solution (catalyst concentration 0.05M) of 0.01 parts by mass, the polymerization reaction starts, the viscosity of the reaction system increases rapidly, and continues to maintain 60 °C for 30 minutes to obtain a uniform polysiloxane premixed material in-situ doped with conductive carbon black nanoparticles.

[0053] The above in-situ doped polysiloxane premixed material was added into a mold, and vulcanized for 8 hours at a vulcanization temperature of 80° C. to obtain in-situ dope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com