Normal pressure dried phenolic aerogel and preparation method thereof

A technology of atmospheric drying and phenolic gel, applied in the field of nanomaterials, can solve the problems of high shrinkage rate of phenolic aerogel, weak skeleton of phenolic aerogel, poor process performance, etc., and achieve good oxidation resistance and burning resistance. Corrosion performance, skeleton strength improvement, shrinkage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a kind of preparation method of normal pressure drying phenolic airgel in the first aspect, described method comprises the steps:

[0031] (1) prepare the grafting reaction solution that comprises novolac resin, silane grafting agent and the first organic solvent, make described novolac resin and silane grafting agent carry out grafting reaction in described grafting reaction solution, obtain silane Grafted phenolic resin;

[0032] (2) adding a curing agent and a second organic solvent to form a curing reaction solution and carry out a curing reaction to obtain a phenolic gel;

[0033] (3) Drying the phenolic gel under normal pressure to obtain the phenolic aerogel.

[0034]In the present invention, first adopt silane grafting agent to carry out grafting reaction to novolac resin, the present invention unexpectedly finds that compared with directly blending silane monomer with phenolic resin or phenolic small molecule monomer, adopting th...

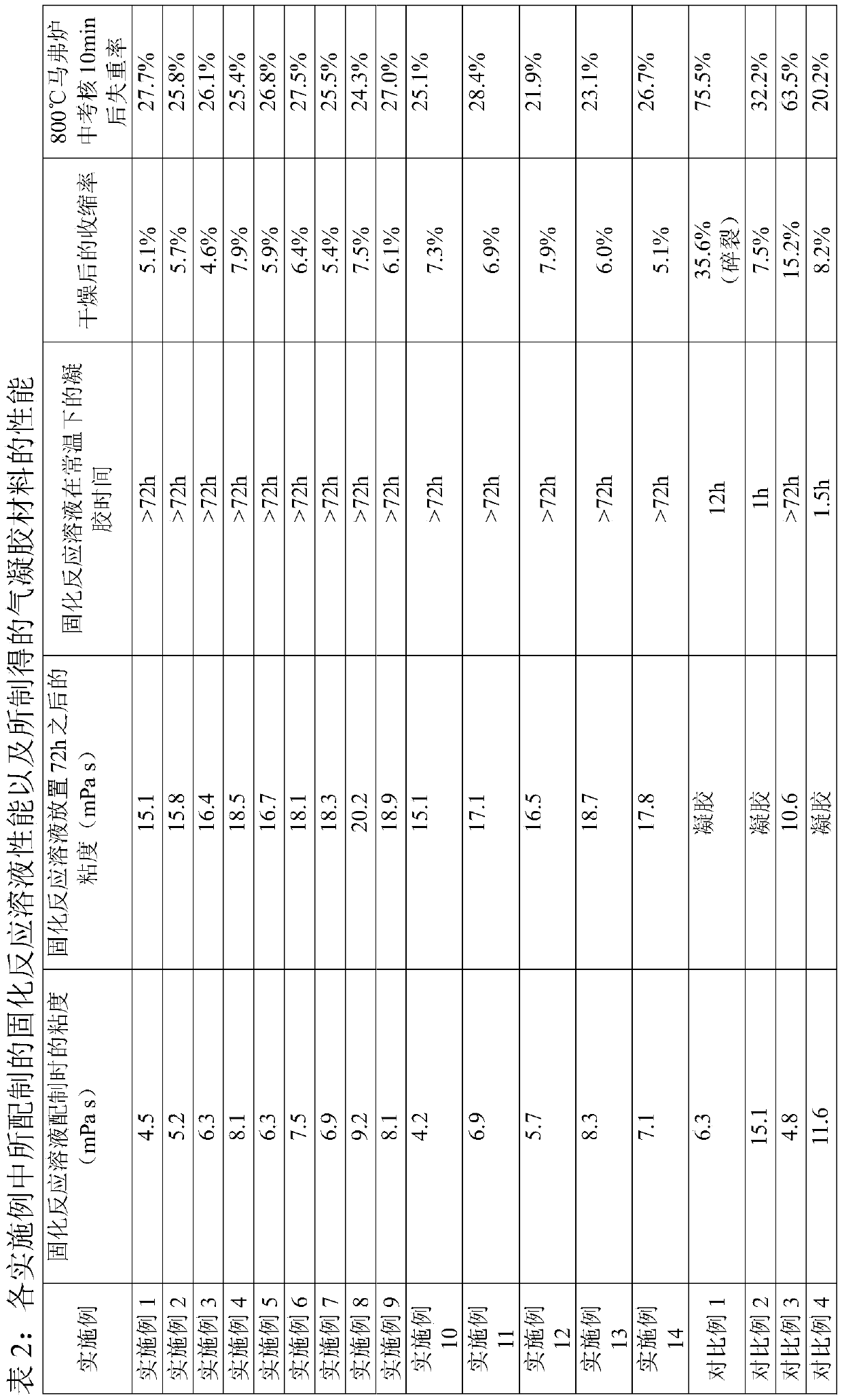

Embodiment 1

[0040] Weigh novolac resin and tetraethyl orthosilicate with a hydroxyl molar ratio of 1:1, dissolve in ethanol solution, prepare a uniform grafting reaction solution, and place it in a three-necked round-bottomed flask. The mass fraction of novolak resin in the grafting reaction solution is 45wt%. 1 wt% acetic acid based on the mass of phenolic resin was added as a grafting catalyst, and the grafting reaction was carried out under reflux at 95° C. for 12 hours.

[0041] Cool down to room temperature after the reaction is over, add ethanol to adjust the solid content to 35wt%, add 10wt% hexamethylenetetramine of the phenolic resin quality as a curing agent, stir until it is completely dissolved, and obtain a solidified reaction solution. The time of standing 72h does not produce gel. Put the curing reaction solution into a metal mold that can be sealed and withstand high pressure, so that the mold cavity is filled and sealed, and placed in an oven at 120° C. for 72 hours to c...

Embodiment 2~14

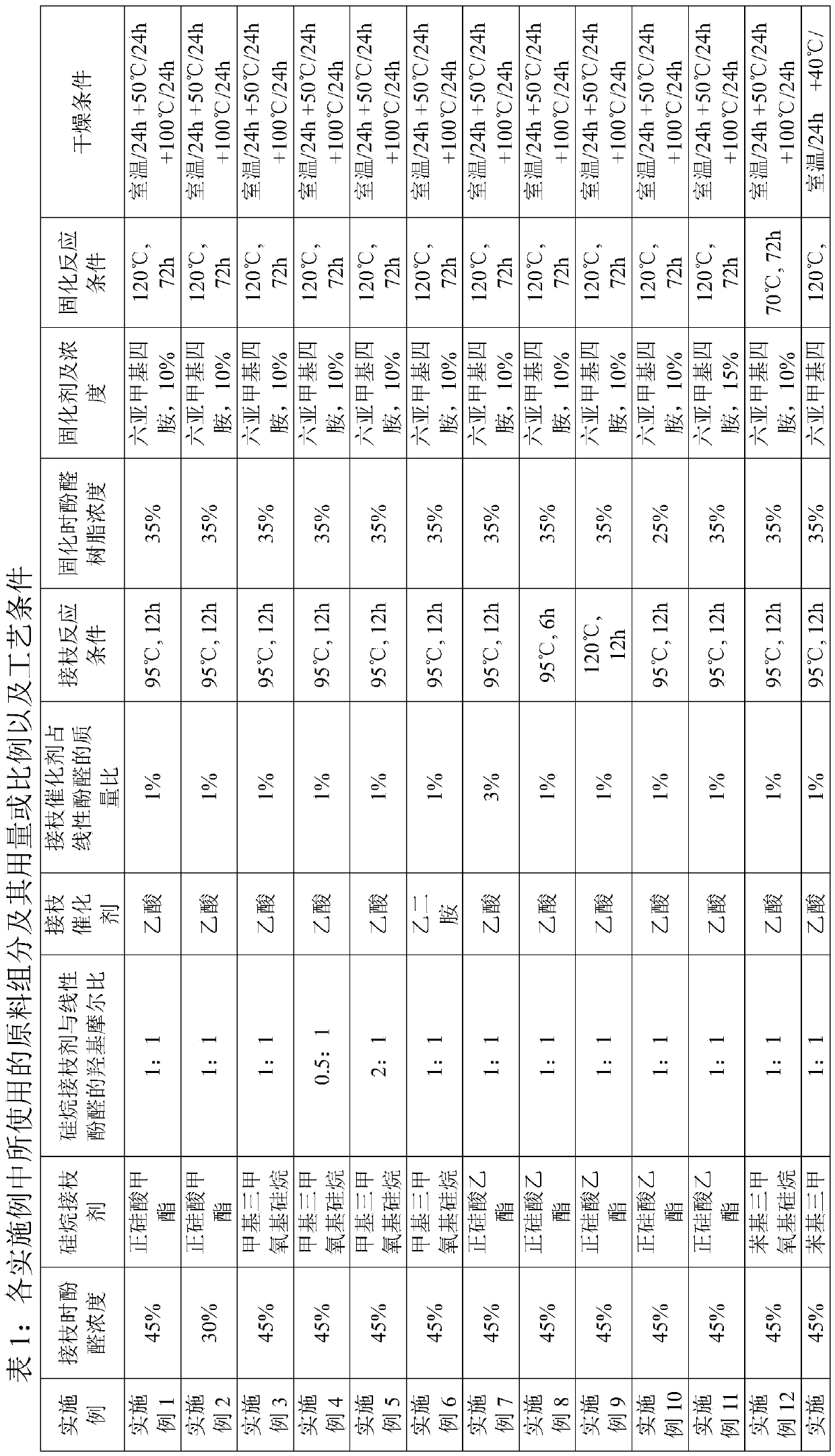

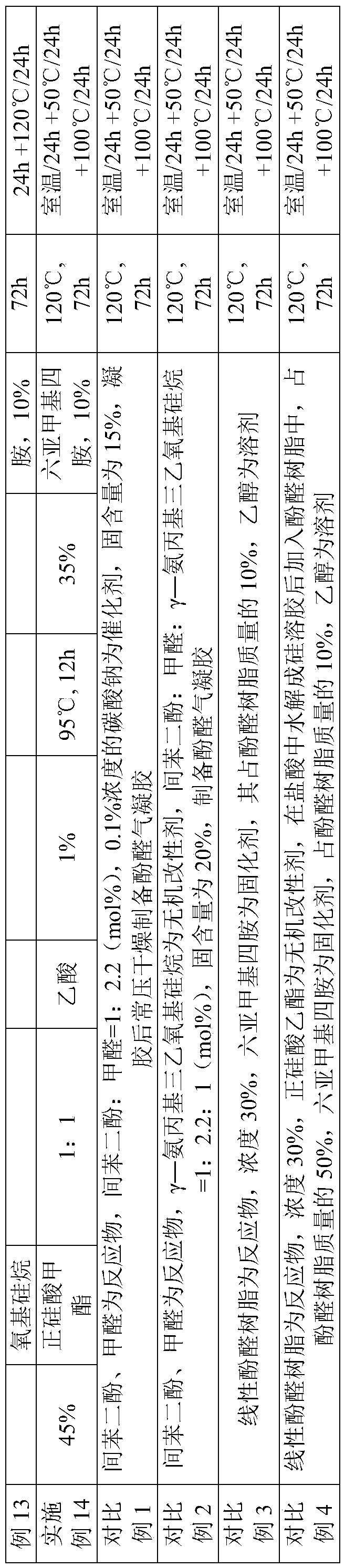

[0044] The process parameters adopted in Examples 2 to 14 are shown in Table 1. Except for the listed parameters, the other unmentioned process parameters are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com