Preparation method of aerogel

An airgel and hydrogel technology, applied in the field of airgel, can solve problems such as environmental pollution, a large amount of organic solvents, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

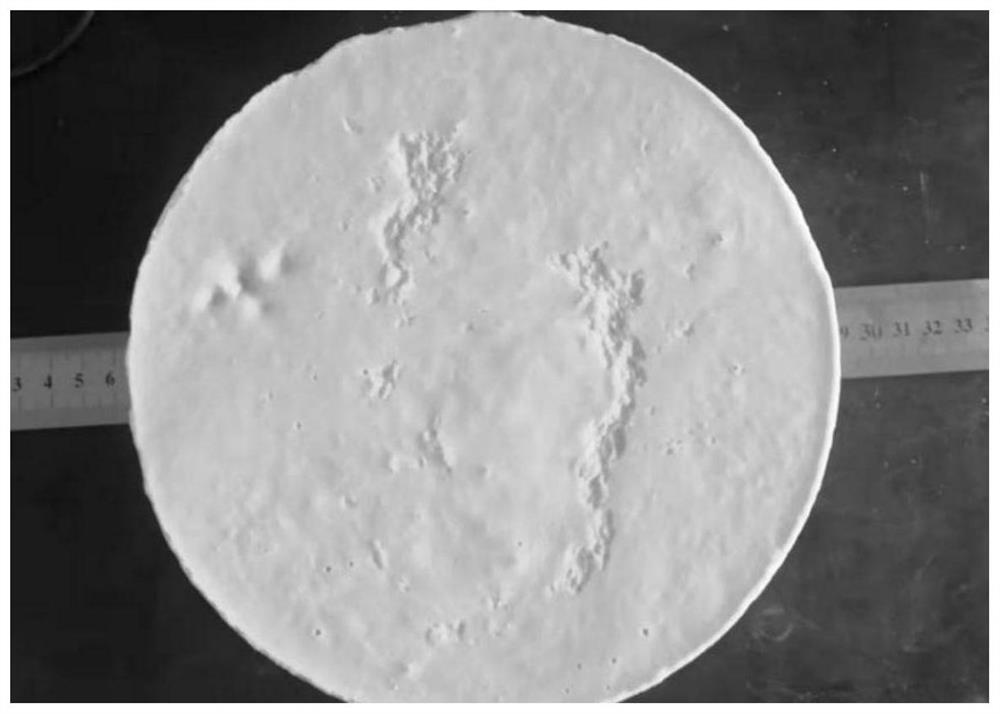

Image

Examples

preparation example Construction

[0034] The invention provides a preparation method of aerogel, comprising the following steps:

[0035] The acidic aqueous solution of the surfactant is subjected to hydrolysis condensation reaction with the tetrafunctional siloxane, the first trifunctional siloxane and the reinforcing agent in turn to obtain a sol system;

[0036] mixing the sol system and the gel catalyst to obtain a hydrogel;

[0037] drying the hydrogel at atmospheric pressure to obtain the aerogel;

[0038] The reinforcing agent includes one or more of the second trifunctional siloxane, the first difunctional siloxane and the first monofunctional siloxane.

[0039] In the present invention, unless otherwise specified, all preparation raw materials are commercially available products well known to those skilled in the art.

[0040] In the present invention, the acidic aqueous solution of the surfactant is subjected to hydrolysis condensation reaction with the tetrafunctional siloxane, the first trifuncti...

Embodiment 1

[0084] Mix 8g of cetyltrimethylamine bromide and 1000mL of deionized water, heat to 60°C to dissolve, then cool to room temperature, add nitric acid to adjust the pH to 2, and obtain an acidic aqueous solution of surfactant;

[0085] 45mL of tetraethyl orthosilicate was added to the acidic aqueous solution of surfactant, stirred at a stirring speed of 300rpm for 60min, and carried out a first-level hydrolysis condensation reaction; then added 145mL of methyltriethoxysilane, and stirred at a stirring speed of 300 45min, carry out secondary hydrolysis condensation reaction; then add 70mL dimethyldiethoxysilane, stir at 300rpm stirring speed for 30min, carry out hydrolysis condensation reaction; then add 40mL aminopropyltrimethoxysilane, stir at 300rpm speed, stir for 30min, carry out hydrolysis condensation reaction, obtain sol system;

[0086] Mix the sol system with ammonia water, adjust the pH value to 7, stir at a stirring speed of 800 rpm for 20 min, and let stand to form a...

Embodiment 2

[0089] Mix 20 g of polyoxyethylene ether and 1000 mL of deionized water and heat to 60° C. to dissolve, then cool to room temperature and add glacial acetic acid to adjust the pH to 4 to obtain an acidic aqueous solution of surfactant;

[0090] Add 30 mL of ethyl orthosilicate to the acidic aqueous solution of surfactant, and stir for 60 min at a stirring speed of 300 rpm to carry out a first-level hydrolysis condensation reaction; then add 180 mL of methyltrimethoxysilane, and stir for 30 min at a stirring speed of 300 rpm. , carry out secondary hydrolysis condensation reaction; then add 60mL dimethyldiethoxysilane, stir 50min at 300rpm stirring speed, carry out hydrolysis condensation reaction; then add 30mL acryloyloxypropyltrimethoxysilane, stir at 300rpm Stirring speed, stirring for 30min, carry out hydrolysis condensation reaction, obtain sol system;

[0091] Mix the sol system with the quaternary ammonium base, adjust the pH value to 8, stir at a stirring speed of 800 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com