Low-temperature melon gel fracturing liquid

A fracturing fluid and low-temperature technology, applied in drilling compositions, chemical instruments and methods, etc., to achieve the effects of increasing the rate of gel breaking, preventing the formation of precipitation, and shortening the gel breaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

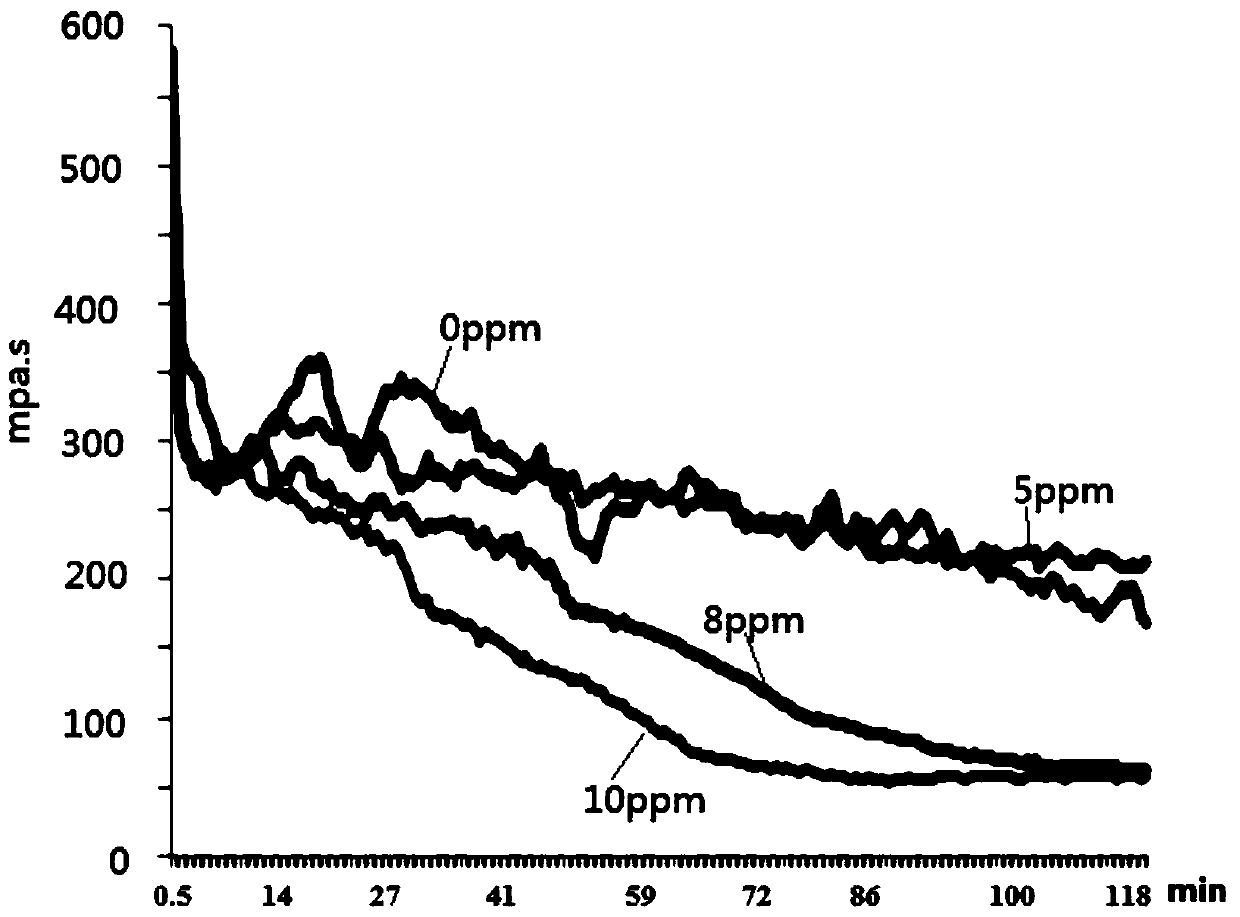

Embodiment 1

[0028] A low-temperature guar gum fracturing fluid, consisting of base fluid, crosslinking agent borax and gel breaker (NH4) 2 S 2 o 8 composition. The base liquid includes the following components in mass percentage: 0.4% hydroxypropyl guar gum, 0.1% formaldehyde, 0.3% drainage aid, 0.02-0.03% sodium hydroxide (adjust the pH value to 11), 1% KCl, low temperature Activator, the rest is water. The mass percentage of borax in the fracturing fluid is 1%. Breaker (NH4) 2 S 2 o 8 The concentration is 200 ppm. The cross-link ratio is 100:5.

[0029] Among them, the low-temperature activator is prepared by the following method: dissolving ligand A in methanol aqueous solution containing 60-75% methanol mass (the mass percentage of ligand A in methanol aqueous solution is 20%), heating to 60°C, using Adjust the pH to 4-5 with citric acid, add AgNO 3 , AgNO 3 The mass percentage is 3% in methanol aqueous solution, stirred evenly, and the pH is adjusted to 7-8 with ammonia wa...

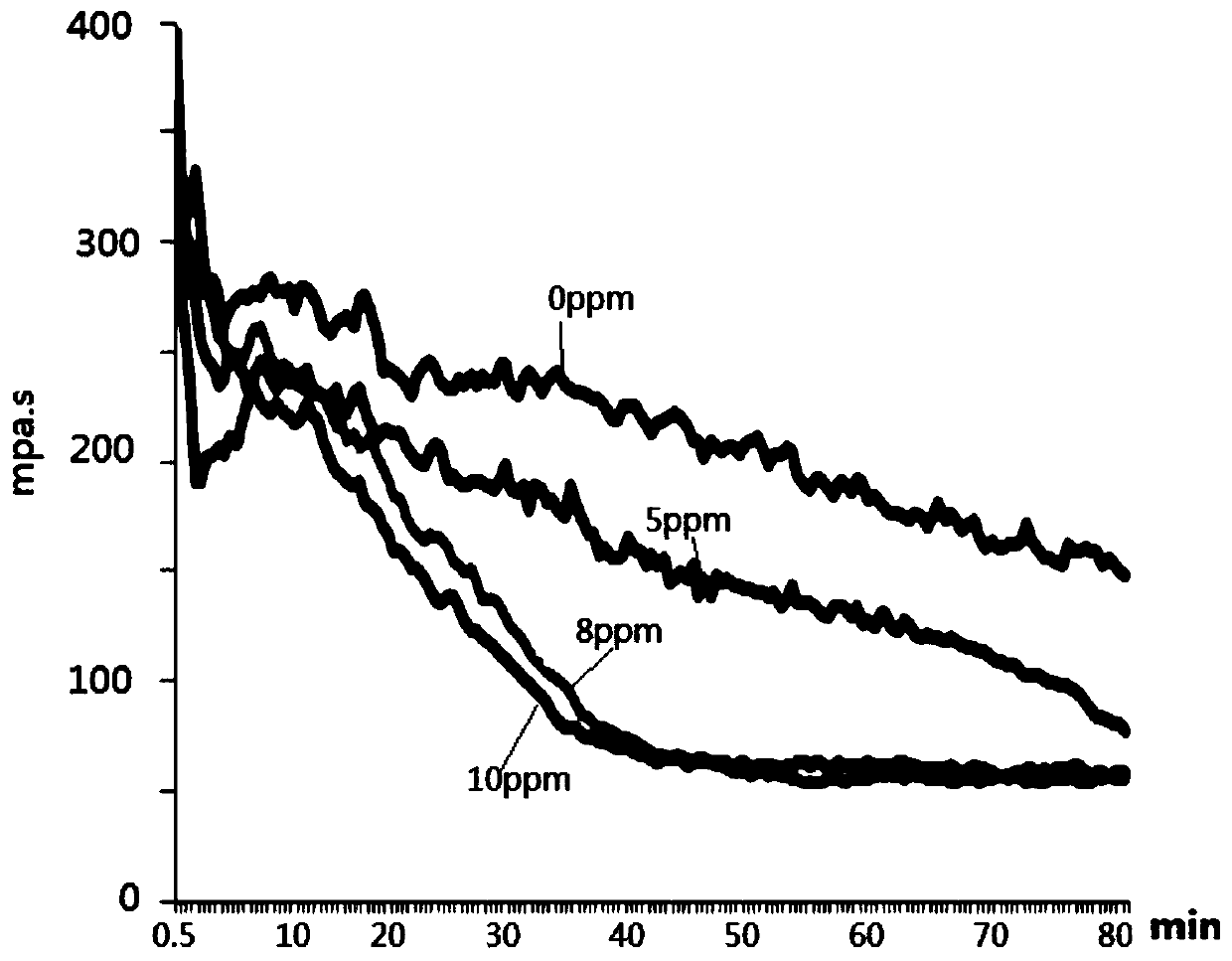

Embodiment 2

[0042] A low-temperature guar gum fracturing fluid, consisting of base fluid, crosslinking agent borax and gel breaker (NH4) 2 S 2 o 8 composition. The base liquid includes the following components in mass percentage: 0.4% hydroxypropyl guar gum, 0.1% formaldehyde, 0.3% drainage aid, 0.02-0.03% sodium hydroxide (adjust the pH value to 11), 1% KCl, low temperature The concentration of activator is 10-30ppm, and the rest is water. The mass percentage of borax in the fracturing fluid is 1%. Breaker (NH4) 2 S 2 o 8 The concentration is 200 ppm. The cross-link ratio is 100:5.

[0043] Among them, the low-temperature activator is prepared by the following method: dissolving ligand B in methanol aqueous solution containing 60-75% of methanol mass, the mass percentage of ligand B in methanol aqueous solution is 35%, heating to 60°C, using lemon Acid to adjust pH to 4-5, add AgNO 3 , AgNO 3 The mass percentage is 5% in methanol aqueous solution, the mixture is stirred evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

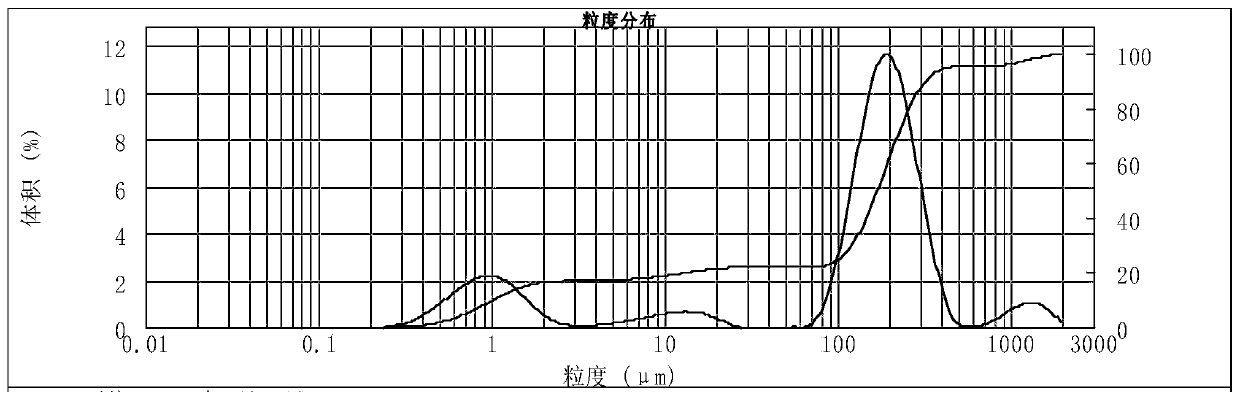

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com