Novel ceramic hot-work die steel

A hot work die steel and ceramic technology, applied in the field of metal-ceramic composite materials, can solve the problem of high cost and achieve the effects of strong toughness, cost saving, toughness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

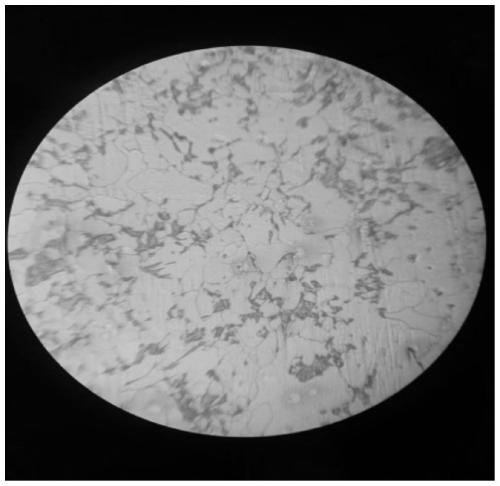

Image

Examples

Embodiment 1

[0043]The new ceramic hot work die steel, in parts by weight, consists of raw materials: 65 parts of steel scrap, 5 parts of kaolin, 6 parts of bauxite, 5 parts of quartz sand, 2 parts of mica, 1 part of bentonite, 2 parts of kyanite, 1.5 parts of spar, 1 part of calcite, 1 part of graphite, 1.5 parts of fluorite, 1 part of feldspar, 1 part of mullite, 5 parts of SiC, 1 part of zeolite, and 1 part of bauxite. Smelting and heat treatment are carried out according to the following technical scheme.

Embodiment 2

[0045] The new ceramic hot work die steel, in parts by weight, consists of raw materials: 70 parts of steel scrap, 2 parts of kaolin, 2 parts of bauxite, 5 parts of quartz sand, 2 parts of mica, 2 parts of bentonite, 1 part of kyanite, 1 part of spar, 1 part of calcite, 1 part of fluorite, 1 part of feldspar, 2 parts of mullite, 4 parts of SiC, 1 part of zeolite, 1 part of wollastonite, 1 part of spinel, 1 part of crystal stone, aluminum Magnesium ore 2 parts. Smelting and heat treatment are carried out according to the following technical scheme.

Embodiment 3

[0047] The new type of ceramic hot work die steel, in parts by weight, consists of raw materials: 60 parts of steel scrap, 8 parts of kaolin, 9 parts of bauxite, 5 parts of quartz sand, 1 part of mica, 1 part of kyanite, and 1 part of barite , 1 part of calcite, 1 part of fluorite, 1 part of feldspar, 2 parts of mullite, 3 parts of SiC, 1 part of zeolite, 3 parts of wollastonite, 1 part of spinel, and 2 parts of bauxite. Smelting and heat treatment are carried out according to the following technical scheme.

[0048] Melting and heat treatment solutions

[0049] Melting process: 1) Check the equipment. Including whether the intermediate frequency furnace, the water flow condition of the induction coil, the furnace wall, the furnace tilting device, the driving of the intermediate frequency machine, etc. are in good condition, and if there is any problem, start it up after repairing it.

[0050] 2) Weigh and add the charge as required, put the metal that is difficult to melt a...

PUM

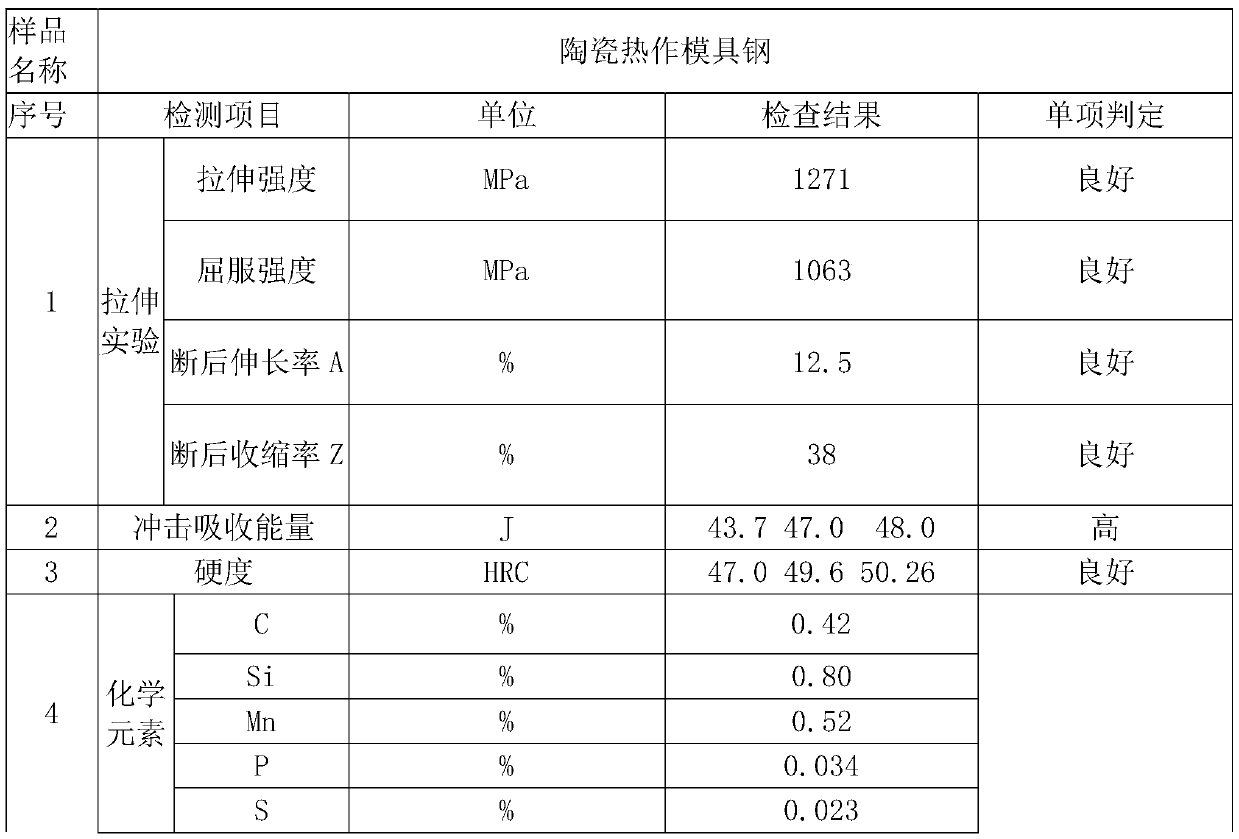

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact absorption energy | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com