Copper piece welding process for power module by using sintered silver paste as bonding agent

A technology for power modules and welding processes, applied in circuits, electrical components, electrical solid devices, etc., can solve the problems of increasing manufacturing costs, natural environment effects, increasing process complexity, etc., to save process time and cost, superior electrical conductivity, Savings on conventional chemical reagents and water cleaning and disposal emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

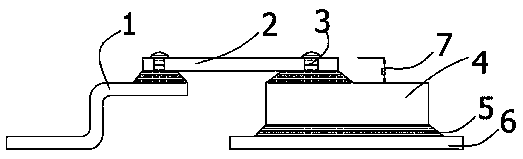

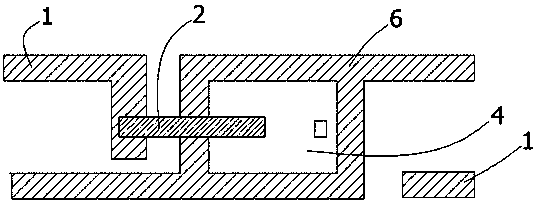

[0039] A power module copper sheet welding process using sintered silver paste as an adhesive, including a copper sheet welding step, in which the sintered silver paste is used as the bonding between the copper sheet and the chip welding area and the frame welding area agent, the welding process includes:

[0040] (a) Die attach film and dicing;

[0041] (b) die attach;

[0042] (c) Dot sintered silver paste: put 3 dots of sintered silver paste on the upper surface of pin 1 and chip 4, the shape of sintered silver paste is hemispherical;

[0043] (d) Copper sheet welding: press the copper sheet welding on the sintered silver paste 3 where the sintered silver paste is placed at point (c), to ensure that the sintered silver paste overflows from the locking hole of the copper sheet,

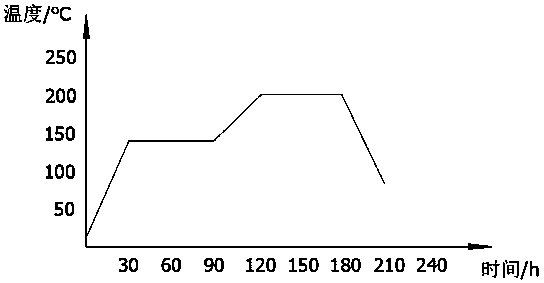

[0044] (e) Solidification of sintered silver paste: then solidified by reflow soldering, using equipment desktop reflow soldering furnace, which is divided into five stages:

[0045] (1) Heating:...

specific Embodiment 2

[0061] A power module copper sheet welding process using sintered silver paste as an adhesive, including a copper sheet welding step, in which the sintered silver paste is used as the bonding between the copper sheet and the chip welding area and the frame welding area agent, the welding process used for high-current power module bonding includes:

[0062] (a) Die attach film and dicing;

[0063] (b) die attach;

[0064] (c) Spot sintered silver paste: spot the sintered silver paste on the upper surface of pin 1 and chip 4, the shape of the sintered silver paste is hemispherical;

[0065] (d) Copper sheet welding: Press the copper sheet welding on the sintered silver paste at point (c) to ensure that the sintered silver paste overflows from the locking hole of the copper sheet.

[0066] (e) Solidification of sintered silver paste: then solidified by reflow soldering, using equipment desktop reflow soldering furnace:

[0067] (1) Heating: the starting temperature is room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com