Method of preparing large-area uniform CIGS thin film solar cell by using In-GA alloy evaporation source

An evaporation source, large-area technology, used in photovoltaic power generation, vacuum evaporation coating, circuits, etc., to achieve uniformity and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

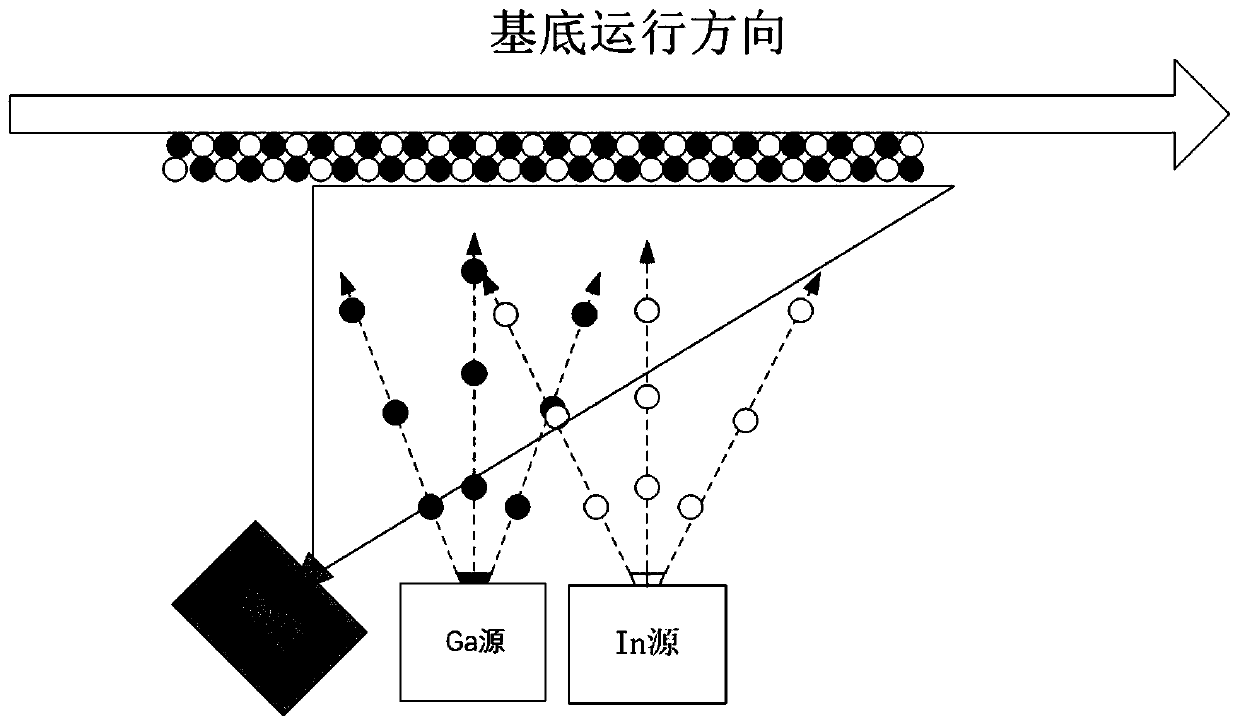

[0056] A method for preparing a large-area uniform CIGS thin-film solar cell using an In-Ga alloy evaporation source. After the soda-lime glass substrate deposited with a molybdenum back electrode layer enters the evaporation source chamber, a one-step co-evaporation process is adopted:

[0057] In a selenium atmosphere, gallium, copper and indium are co-evaporated to deposit selenium, gallium, copper and indium on the substrate. The evaporation source of gallium and indium is an indium gallium alloy source. The evaporation temperature of the indium alloy source and the indium gallium alloy source is controlled at 800-1200°C, the selenium atmosphere is formed by evaporating elemental selenium, and the temperature of evaporating elemental selenium is controlled at 300-650°C; elemental copper is used as the evaporation source of copper, and the evaporation of copper The temperature is controlled at 1000-1500°C.

[0058] The speed of the substrate after entering the evaporation s...

Embodiment 2

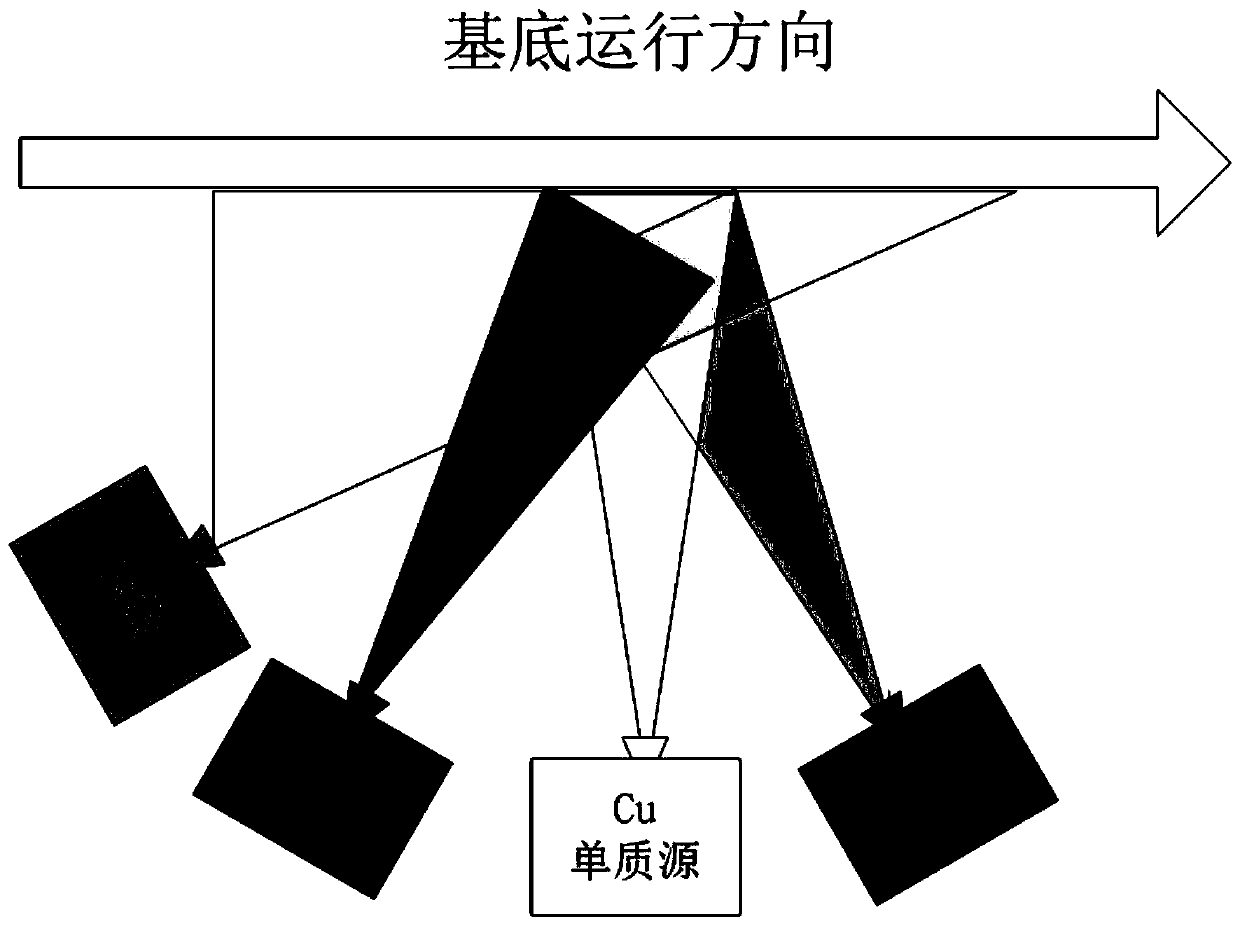

[0063] A method for preparing a large-area uniform CIGS thin-film solar cell using an In-Ga alloy evaporation source. After the soda-lime glass substrate deposited with a molybdenum back electrode layer enters the evaporation source chamber, a two-step co-evaporation process is adopted:

[0064] Step 1: co-evaporate gallium and indium in a selenium atmosphere to deposit selenium, gallium and indium on the substrate;

[0065] Step 2: Copper is evaporated in a selenium atmosphere, so that selenium and copper are deposited on the substrate.

[0066] The evaporation source of gallium and indium is an indium-gallium alloy source. The indium-gallium alloy source includes a gallium-rich alloy source and an indium-rich alloy source. The evaporation temperature of the indium-gallium alloy source is controlled at 800-1200°C. The temperature of elemental selenium is controlled at 300-650°C; elemental copper is used as the evaporation source of copper, and the evaporation temperature of c...

Embodiment 3

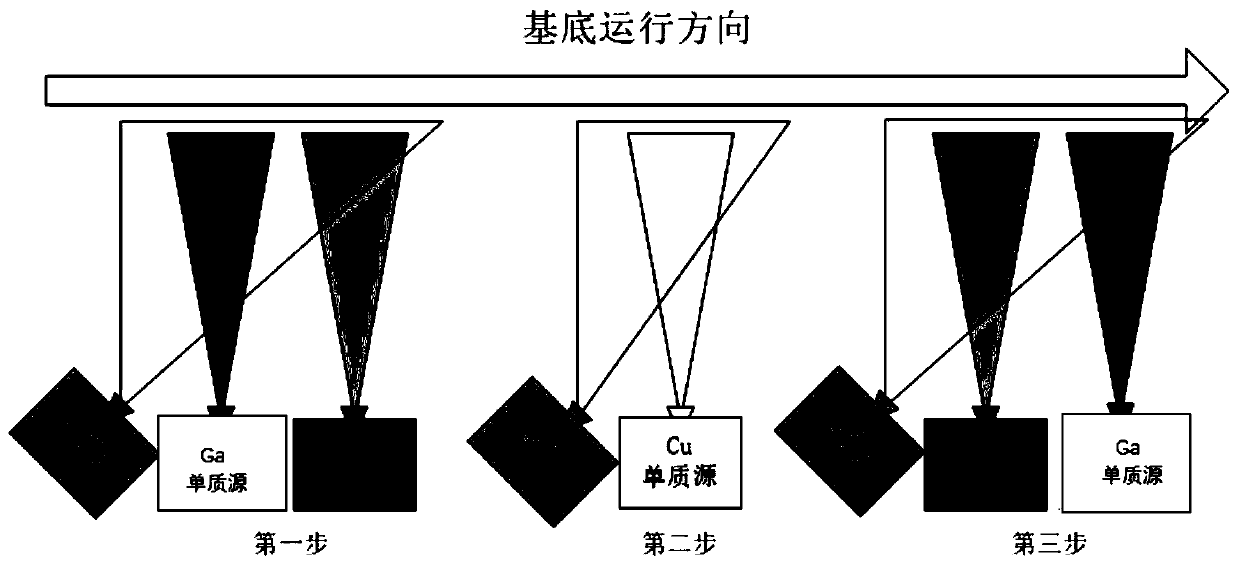

[0075] A method for preparing a large-area uniform CIGS thin-film solar cell using an In-Ga alloy evaporation source. After the soda-lime glass substrate deposited with a molybdenum back electrode layer enters the evaporation source chamber, a three-step co-evaporation process is adopted:

[0076] Step 1: co-evaporate gallium and indium in a selenium atmosphere to deposit selenium, gallium and indium on the substrate;

[0077] Step 2: In a selenium atmosphere, evaporate copper to deposit selenium and copper on the substrate;

[0078] Step 3: co-evaporating gallium and indium in a selenium atmosphere to deposit selenium, gallium and indium on the substrate.

[0079] The evaporation source of gallium and indium is an indium-gallium alloy source. The indium-gallium alloy source includes a gallium-rich alloy source and an indium-rich alloy source. The evaporation temperature of the indium-gallium alloy source is controlled at 800-1200°C. The temperature of elemental selenium is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com