Method for treating inorganic solid electrolyte by using phosphorus-containing organic substance

A technology of solid electrolyte and organic matter, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, circuits, etc., can solve the problems of large-scale, low-cost operations, limitations, etc., and achieve excellent lithium ion conductivity, mild conditions, and The effect of maintaining structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of LLZTO

[0042] 4.88gLa 2 o 3 , 2.16gZrO 2 , 0.55gTa 2 o 5 , 3gLi 2 CO 3 Place in a 500ml agate ball mill jar, mill at 400r / min for 12h, put the milled product in a muffle furnace, and calcinate at 900°C for 10h. Obtain garnet-type inorganic solid-state electrolyte Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 (LLZTO) calcined powder.

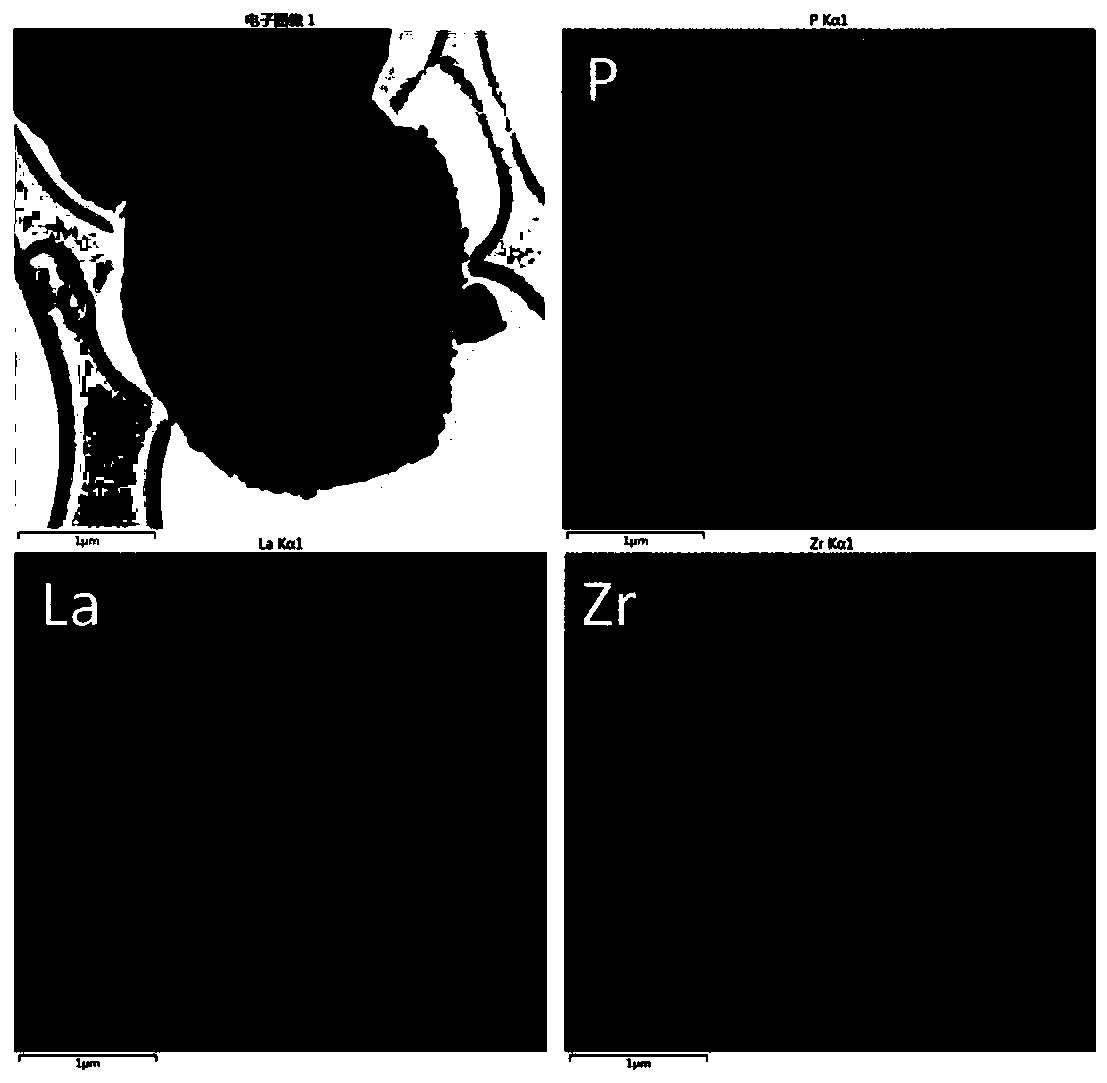

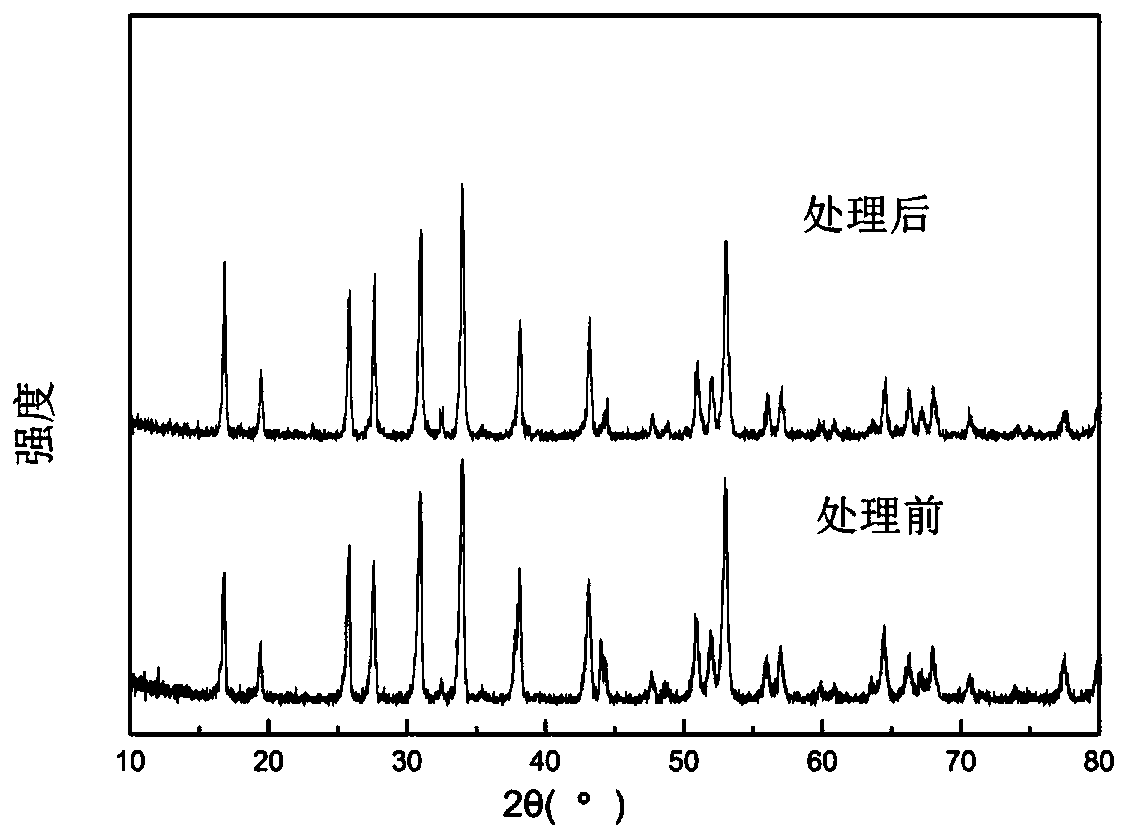

[0043] 2. Dealing with LLZTO

[0044] Disperse 1g of LLZTO calcined powder into 100ml of methanol, add 0.1g of hexachlorotrimeric phosphazene, stir for 2h, place in a water bath at 80°C and evaporate to dryness, and place the material obtained after evaporation in a muffle furnace at 750°C Calcined for 2 hours and cooled naturally to obtain the treated LLZTO. The processed LLZTO material and untreated LLZTO calcined powder were respectively pressed into tablets in a 12mm mold under a pressure of 20MPa, and the pressed tablets were calcined at 1120°C for 16h, fired into LLZTO ceramic sheets, and cooled naturally . The...

Embodiment 2

[0046] Disperse 1 g of the LLZTO calcined powder prepared in Example 1 into 100 ml of methanol, add 5%, 10%, and 20% of the mass of hexachlorotrimeric phosphazene respectively, stir for 2 hours, and evaporate to dryness in a water bath at 80°C , the material obtained after evaporation to dryness was placed in a muffle furnace, calcined at 750°C for 2h, and cooled naturally to obtain the treated LLZTO. The obtained processed LLZTO material was pressed into a tablet in a 12 mm mold under a pressure of 20 MPa, and the pressed sheet was calcined at 1120° C. for 16 hours to be fired into a LLZTO ceramic sheet and cooled naturally. The cooled LLZTO ceramic flakes were ground into powder for characterization. The obtained materials were respectively dispersed in water at a ratio of 1:10, stirred ultrasonically, left to stand for 30 minutes, and the pH value was tested. The results are shown in Table 1. It can be seen from the test results that the method of the invention effectively...

Embodiment 3

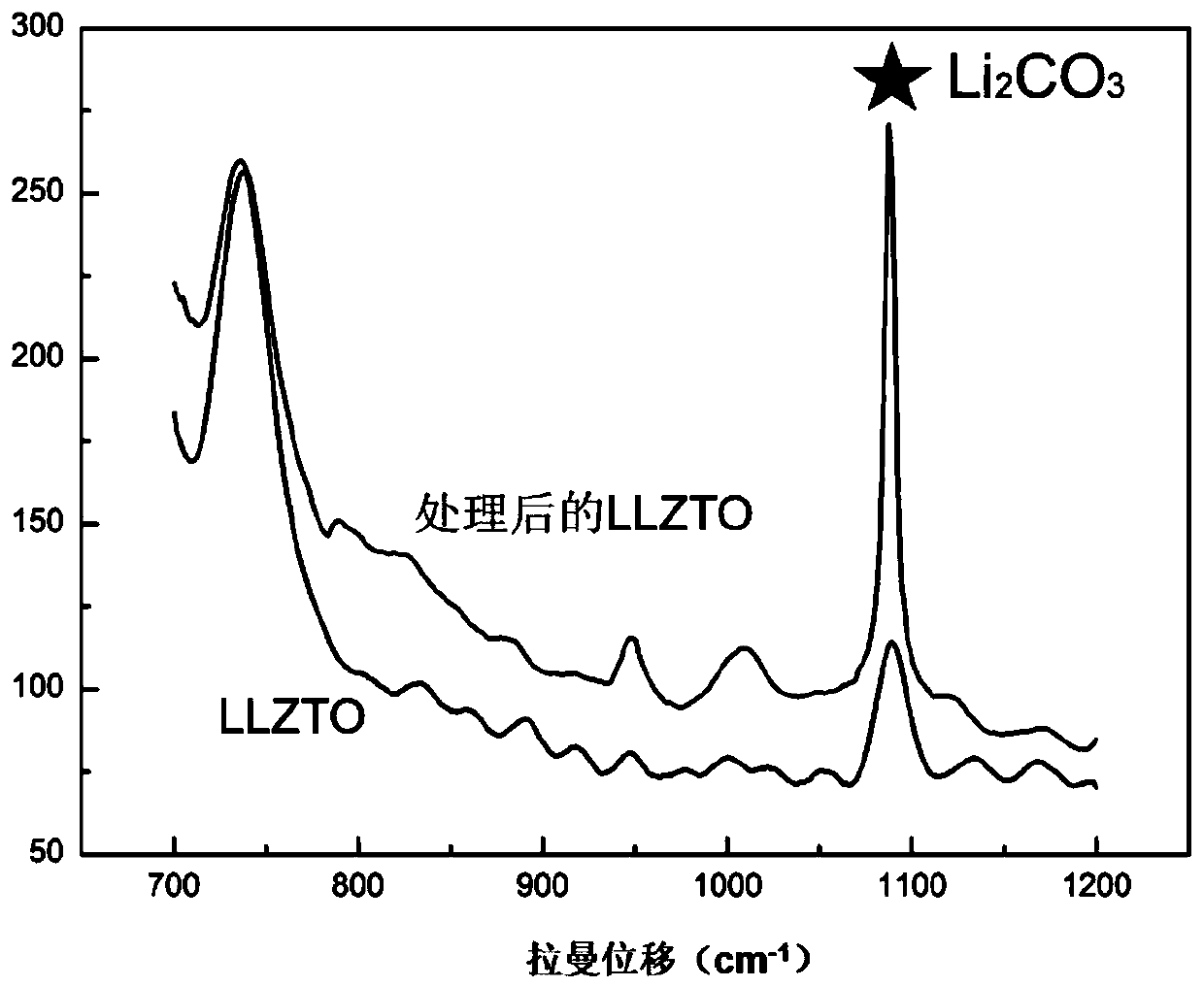

[0050] Disperse 1 g of the LLZTO calcined powder prepared in Example 1 into 100 ml of methanol, add 0.04 g of hexachlorotrimeric phosphazene, stir for 2 h, place it in a water bath at 80 ° C and evaporate to dryness, and place the material obtained after evaporation to dryness in a horse In a Furnace, calcined at 750°C for 2h, and cooled naturally to obtain the treated LLZTO. The obtained treated LLZTO material was pressed into a tablet in a 12mm mold under a pressure of 20MPa, and the pressed sheet was calcined at 1120°C for 16h to be fired into a LLZTO ceramic sheet and cooled naturally. The cooled LLZTO ceramic flakes were ground into powder for characterization. The processed LLZTO and the untreated LLZTO were subjected to micro-Raman test, the test wavelength was 532nm, and the test results were as follows image 3 As shown, the Li contained in the treated LLZTO 2 CO 3 significantly decreased, indicating that during the calcination process, the phosphorus reacted with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com