Sugar free tea flavor biscuits with crisp taste and preparation method of sugar free tea flavor biscuit

A crispy, sugar-tea technology, which is applied in the field of sugar-free tea-flavored biscuits and its preparation, can solve the problems of affecting the cohesion of biscuits, biscuits are too brittle, and the taste is general, so as to improve the taste and texture, improve the taste of eating, and have a unique flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

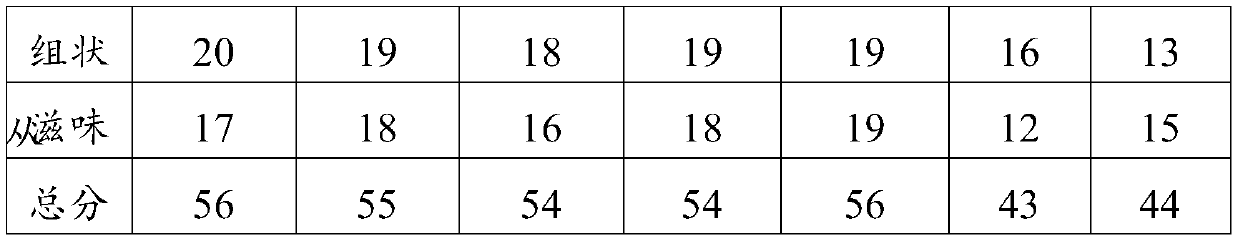

Embodiment 1

[0027] A sugar-free tea-flavored biscuit with a crisp mouthfeel, wherein the ingredients are calculated by weight: 280 parts of wheat flour, 8 parts of edible salt, 60 parts of tea dregs, 10 parts of glycerin, 6 parts of compounding agent, 8 parts of flavoring agent, plant 15 parts of refined oil, 70 parts of water.

[0028] A sugar-free tea-flavored biscuit with a crisp mouthfeel, the preparation method comprising the following steps:

[0029] S1: Soak the raw tea dregs in clean water for 1.5-2 hours, put them into a hot air circulation drying box after washing, and dry them until the water content is 6%, then put them into a grinder for crushing, and pass through 100 Mesh sieve;

[0030] S2: Take the pulverized tea residue powder, mix it with 0.5% sodium chloride solution with a solid-liquid ratio of 1:10-15, then add 0.05mol / L Tris-HCl buffer solution to the mixed solution, Adjust the pH of the mixture to 7.8-8.0, add the complex enzyme solution at an enzyme-to-substrate ...

Embodiment 2

[0044] A sugar-free tea-flavored biscuit with a crisp mouthfeel, wherein the ingredients are by weight: 230 parts of wheat flour, 8 parts of edible salt, 60 parts of tea dregs, 5 parts of glycerin, 6 parts of compounding agent, 8 parts of flavoring agent, plant 15 parts of refined oil, 60 parts of water.

[0045] A sugar-free tea-flavored biscuit with a crisp mouthfeel, the preparation method comprising the following steps:

[0046] S1: Soak the raw tea dregs in clean water for 1.5-2 hours, put them into a hot air circulation drying box after washing, and dry them until the water content is 6%, then put them into a grinder for crushing, and pass through 100 Mesh sieve;

[0047] S2: Take the pulverized tea residue powder, mix it with 0.5% sodium chloride solution with a solid-liquid ratio of 1:10-15, then add 0.05mol / L Tris-HCl buffer solution to the mixed solution, Adjust the pH of the mixture to 7.8-8.0, add the complex enzyme solution at an enzyme-to-substrate mass ratio o...

Embodiment 3

[0061] A sugar-free tea-flavored biscuit with a crisp mouthfeel, wherein the ingredients are by weight: 260 parts of wheat flour, 15 parts of edible salt, 60 parts of tea dregs, 10 parts of glycerin, 6 parts of compounding agent, 5 parts of flavoring agent, plant 10 parts of refined oil, 70 parts of water.

[0062] A sugar-free tea-flavored biscuit with a crisp mouthfeel, the preparation method comprising the following steps:

[0063] S1: Soak the raw tea dregs in clean water for 1.5-2 hours, put them into a hot air circulation drying box after washing, and dry them until the water content is 6%, then put them into a grinder for crushing, and pass through 100 Mesh sieve;

[0064] S2: Take the pulverized tea residue powder, mix it with 0.5% sodium chloride solution with a solid-liquid ratio of 1:10-15, then add 0.05mol / L Tris-HCl buffer solution to the mixed solution, Adjust the pH of the mixed solution to 7.8~8.0, add the compound enzyme solution according to the enzyme-subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com