High calcium peptide instant fish ball and production method thereof based on ultra-fine pulverization by wet processing

A technology of wet ultrafine grinding and production method, which is applied in the field of deep processing of aquatic products, can solve problems such as difficult protein, enzymatic hydrolysis, complex process, etc., and achieve the goal of increasing peptide calcium chelation rate, preventing fatty acid rancidity, and super high nutritional value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

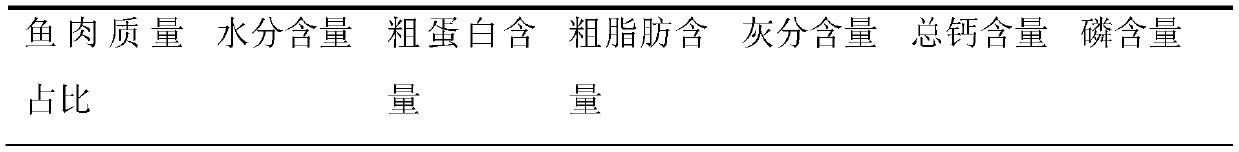

[0039] The skeleton of the white banana perch was taken to analyze the basic components such as the proportion of fish meat, moisture, crude protein, crude fat, ash, total calcium content and phosphorus content. As can be seen from Table 1, the fish skeleton contains a large amount of fish meat (33.17%), rich in crude protein (16.65%), crude fat (3.03%), calcium (8.46%), phosphorus (3.89%), and the ash content is also Up to 8.46%. It shows that the skeleton of white banana perch is a resource with high protein and calcium, and the protein and calcium in the raw material can be chelated into chelating peptides by certain technology, so as to improve the nutritional value.

[0040] Table 1 Basic nutrient composition of fish skeleton (%, wet weight)

[0041]

[0042]

Embodiment 2

[0044] 1. Prepare the white banana perch fish skeleton slurry: clean 10 kg of white banana perch fish skeleton raw materials, chop them into 2×3cm size to meet the requirements of the feed port of the wet ultrafine pulverizer, and adjust the filter screen of the discharge port of the machine The size of the net is 100 mesh, and the skeleton of the white banana perch is crushed into 10 kg of fish skeleton slurry.

[0045] 2. Preparation of fish skeleton peptide: add 0.05 kg of low-temperature protease to 10 kg of fish skeleton pulp, and enzymatically hydrolyze it for 5 hours, so that the fish protein in the fish bone pulp is transformed into fish peptide with an average molecular weight of 10KDa; heat the fish bone pulp to 50°C Afterwards, the enzyme was incubated for 10 minutes to obtain the white banana perch fish skeleton peptide solution.

[0046] 3. Preparation of white banana perch fish skeleton peptide calcium chelate: add 0.075 kg of edible lactic acid to 10 kg of white...

Embodiment 3

[0052] 1. Preparation of tilapia fish skeleton slurry: clean 10 kg of tilapia fish skeleton raw materials, chop them into 2×3cm size to meet the requirements of the feed port of the wet ultrafine pulverizer, and adjust the filter screen of the discharge port of the machine The size of the net is 120 mesh, and the tilapia fish skeleton is crushed into 10 kg of fish skeleton slurry.

[0053] 2. Preparation of tilapia fish skeleton peptide: 0.05 kg of low-temperature protease was added to 10 kg of tilapia fish skeleton slurry, and enzymolysis was carried out for 4.5 hours, so that the tilapia fish protein in the fish bone slurry was transformed into peptides with an average molecular weight of 20KDa Fish peptide: heat the fish bone slurry to 50°C and inactivate the enzyme for 10 minutes to obtain the tilapia fish skeleton peptide solution.

[0054] 3. Preparation of tilapia fish skeleton peptide calcium chelate: add 0.05 kg of edible lactic acid to 10 kg of tilapia fish skeleton ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com