A kind of quick-setting anti-cracking cold pouring material for pavement crack repair and preparation method thereof

A pavement crack and quick-setting technology, which is applied in the field of road engineering crack repair materials, can solve problems such as slow curing speed, low temperature crack resistance, insufficient toughness, and traffic delays, and achieve strong adhesion, convenient and fast construction, and guaranteed repair effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present disclosure also provides a method for preparing the above-mentioned quick-setting and cooling joint filling material for repairing pavement cracks. The steps are as follows:

[0055] (1) Preparation of SBR latex-modified emulsified asphalt: weigh the asphalt by weight, and heat the asphalt to 130-150°C; weigh the cationic surfactant, acidity regulator, SBR latex and water by weight, under stirring mode Mix uniformly and maintain the temperature at 60-70°C; process and emulsify the asphalt and the above-mentioned mixed solution under a colloid mill for 5-8 minutes, wherein the rotational speed of the colloid mill is set to 4000-8000 rpm; carry out the SBR latex with the cationic emulsified asphalt prepared above. Mix evenly to obtain SBR latex modified emulsified asphalt.

[0056] (2) cooling the SBR latex modified emulsified asphalt prepared in (1) to 20-45° C., then adding corresponding amounts of defoaming agent, early-strength agent and water-reducing age...

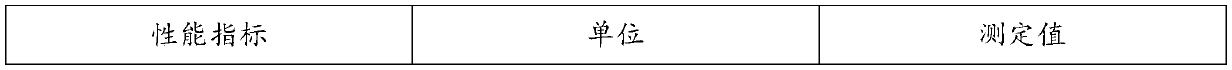

Embodiment 1

[0074] A preparation method of a quick-setting and cooling joint filling material used for repairing pavement cracks, comprising the following steps:

[0075] (1) Weigh 800g of heavy traffic asphalt AH-70, and heat the asphalt to 135°C; Weigh 60g of cationic surfactant (quaternary ammonium salt), 50g of SBR latex, 40g of acidity regulator (acetic acid) and 180g of water , mix evenly under stirring mode and maintain the temperature at 70°C; process and emulsify the asphalt and the above mixture under a colloid mill for 5 minutes, wherein the rotational speed of the colloid mill is set to 8000rpm, and mix the SBR latex with the cationic emulsified asphalt prepared above. Evenly, the SBR latex modified emulsified asphalt is obtained.

[0076] (2) Cool the SBR latex modified emulsified asphalt prepared in (1) to 30°C, then add 25 g of calcium chloride, 15 g of polyether-polyetheramine, and 30 g of naphthalene sulfonate formaldehyde polymer, and stir at 500 rpm 5min to obtain A co...

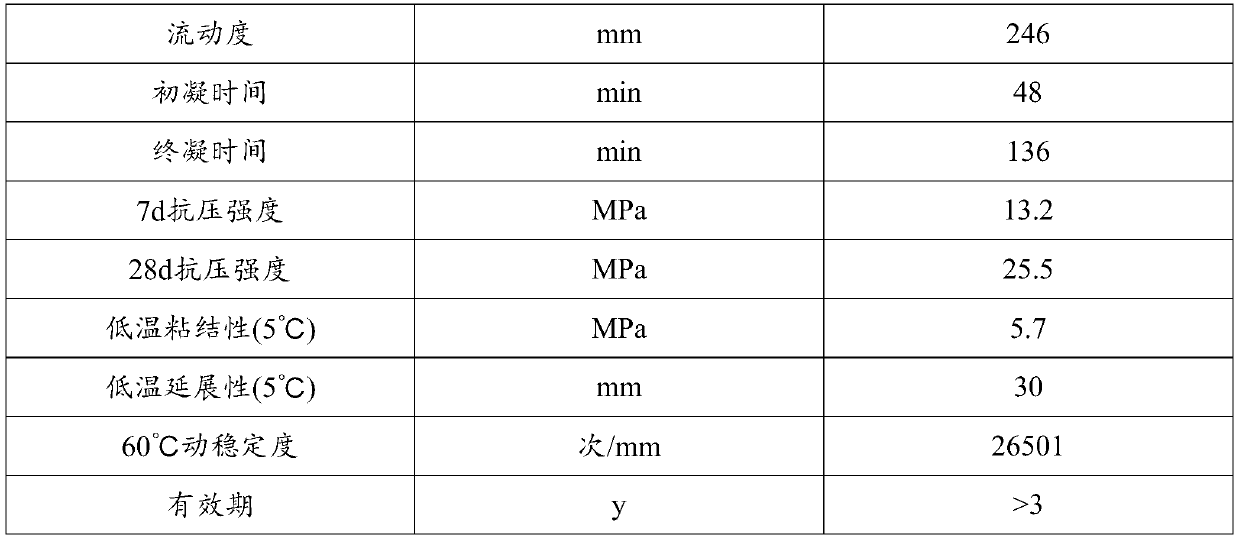

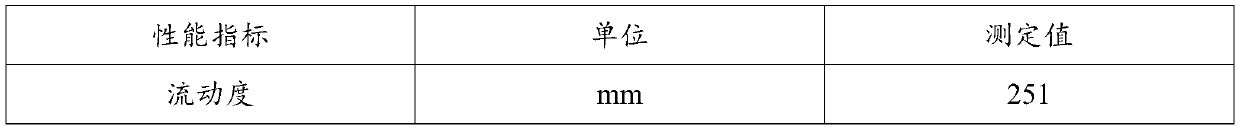

Embodiment 2

[0085] A preparation method for a quick-setting cold filling material for pavement crack repair, comprising the steps of:

[0086] (1) Weigh 700g of heavy traffic road asphalt AH-50, and heat the asphalt to 130°C; weigh 100g of cationic surfactant (alkylimidazolinium salt), 80g of SBR latex, 50g of acidity regulator (acetic acid) and Mix 200g of water evenly in the stirring mode and keep the temperature at 70°C; process and emulsify the asphalt and the above mixed solution under the colloid mill for 5 minutes, wherein the speed of the colloid mill is set to 4000rpm, mix the SBR latex with the cationic emulsified asphalt prepared above Mix evenly to obtain SBR latex modified emulsified asphalt.

[0087] (2) Cool the SBR latex modified emulsified asphalt prepared in (1) to 20°C, then add 10g of aluminum chloride, 10g of organic silicon, and 20g of lignosulfonate, and stir at 300rpm for 5min to obtain component A.

[0088] (3) Weigh 650g of red mud and sieve it through 1mm to ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com