A kind of emulsified asphalt compound red mud-boron mud filling grouting material and preparation method thereof

A technology of emulsified asphalt and grouting material, applied in the field of road engineering grouting material, can solve the problems of inflexible strength control, long setting time, insufficient cohesion, etc., to ensure the repair effect, low price, improve and adjust the strength and the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

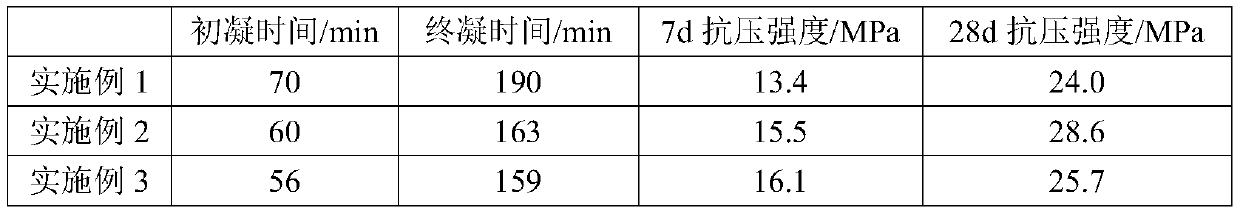

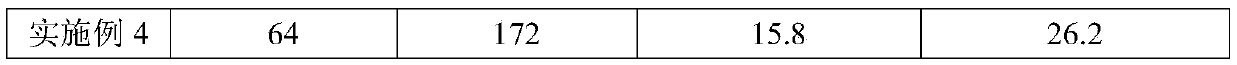

Examples

Embodiment 1

[0046] A method for preparing emulsified asphalt compound red mud-boron mud filling grouting material, comprising the following steps:

[0047] (1) Weigh 900g of heavy traffic road asphalt AH-50, and heat the asphalt to 135°C; weigh 45g of cationic surfactant (quaternary ammonium salt), 40g of acidity regulator (acetic acid) and 180g of water, Mix evenly and keep the temperature at 50°C; process and emulsify the asphalt and the above mixed solution under the colloid mill for 5 minutes, wherein the speed of the colloid mill is set at 6500rpm;

[0048] (2) Weigh 90 g of water glass, 120 g of ordinary Portland cement (grade 42.5) and 90 g of plaster of paris, stir evenly in a mixer, and control the speed at 75 rpm to obtain the curing agent.

[0049] (3) Take 600g of cationic emulsified asphalt prepared in step (1), and add sintered red mud (with a specific surface area of 360 to 390m 2 / kg range) 400g, 400g of boron mud and 300g of curing agent prepared by capturing (2), stir...

Embodiment 2

[0052] A method for preparing emulsified asphalt compound red mud-boron mud filling grouting material, comprising the following steps:

[0053] (1) Weigh 800g of heavy traffic road asphalt AH-30, and heat the asphalt to 150°C; weigh 60g of cationic surfactant (alkylimidazolinium salt), 40g of acidity regulator (hydrochloric acid) and 100g of water, Mix evenly in the stirring mode and maintain the temperature at 60°C; process and emulsify the asphalt and the above mixed solution under the colloid mill for 8 minutes, and the speed of the colloid mill is set at 7000rpm.

[0054] (2) Weigh 90 g of water glass, 150 g of ordinary Portland cement (grade 42.5) and 60 g of plaster of paris, and stir them evenly in a mixer with the speed controlled at 60 rpm.

[0055] (3) Take 400 g of cationic emulsified pitch prepared in step (1), and add sintered red mud (with a specific surface area of 370 to 430 m 2 / kg range) 800g, 600g of boron mud and 300g of curing agent prepared in step (2)...

Embodiment 3

[0058] A method for preparing emulsified asphalt compound red mud-boron mud filling grouting material, comprising the following steps:

[0059] (1) Weigh 900g of heavy traffic road asphalt AH-70, and heat the asphalt to 140°C; weigh 15g of cationic surfactant (lignin), 20g of acidity regulator (acetic acid) and 150g of water, and mix it under stirring mode Mix evenly and maintain the temperature at 40°C; process and emulsify the asphalt and the above mixed solution under the colloid mill for 3 minutes, wherein the speed of the colloid mill is set at 4000rpm.

[0060] (2) Weigh 80 g of water glass, 110 g of ordinary Portland cement (grade 52.5) and 50 g of plaster of paris, and stir them evenly in a mixer with the rotational speed controlled at 70 rpm.

[0061] (3) Take 300g of cationic emulsified asphalt prepared in step (1), and add sintered red mud (with a specific surface area of 360 to 400m 2 / kg range) 300g, 300g of boron mud and 100g of curing agent prepared in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com