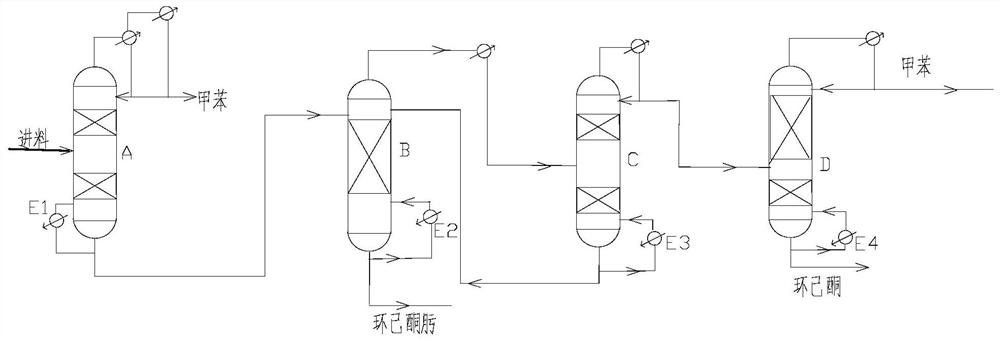

Method for separating cyclohexanone oxime, cyclohexanone and toluene from ammoximation reaction product

An ammoximation reaction and cyclohexanone oxime technology is applied in the field of cyclohexanone and toluene to separate cyclohexanone oxime, so as to achieve the effects of reducing the amount of toluene, reducing the difficulty of recovery and reducing the probability of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

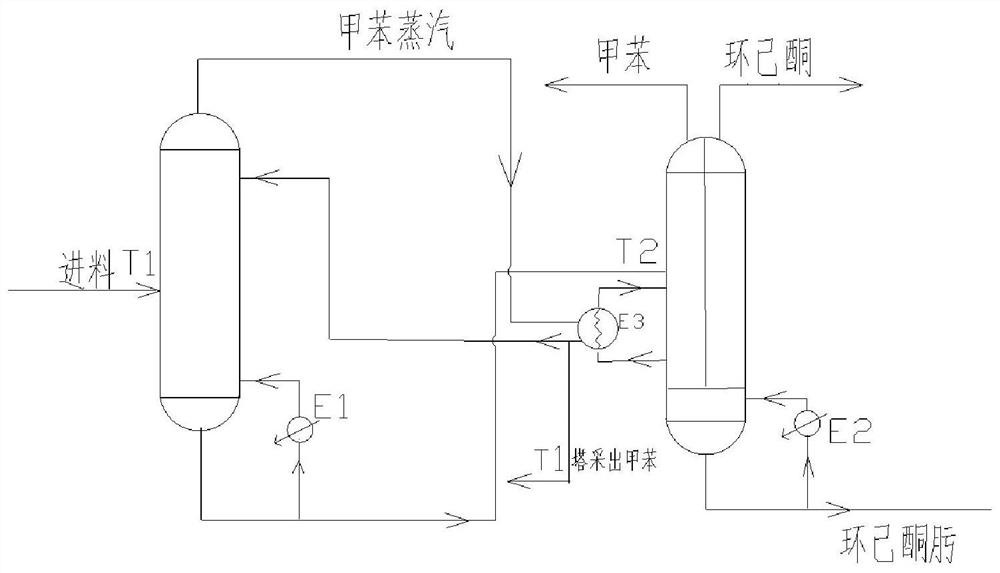

Embodiment 1

[0023] A method for separating cyclohexanone oxime, cyclohexanone and toluene from an ammoximation reaction product. Taking a 100,000-ton / year device as an example, the cyclohexanone oxime content is 24.7%, the toluene content is 73.1%, and the cyclohexanone oxime content is 73.1%. The mixture with hexanone content of 0.2% and water content of 2% is added to the pressurized toluene tower T1, the operating pressure of the pressurized toluene tower T1 is 150kpa, the top temperature is 118°C, and 20-30% of toluene and toluene are distilled from the top of the tower. All the moisture in the material, the top steam of the tower enters the intermediate reboiler E3, and after condensing to a temperature 15°C higher than the reboiler feed temperature of E3, it enters the second condenser and is further condensed to 45°C and enters the reflux tank for phase separation, and the water phase is collected. out, part of the toluene liquid is refluxed into the tower, part of it is extracted, ...

Embodiment 2

[0027] A method for separating cyclohexanone oxime, cyclohexanone and toluene from an ammoximation reaction product. Taking a 100,000-ton / year device as an example, the cyclohexanone oxime content is 24.7%, the toluene content is 73.1%, and the cyclohexanone oxime content is 73.1%. A mixture with a hexanone content of 0.2% and a water content of 2% is added to the pressurized toluene tower T1, the operating pressure of the pressurized toluene tower T1 is 190kpa, the top temperature is 127°C, and 20-30% of toluene and toluene are distilled from the top of the tower. All the moisture in the material, the overhead steam enters the intermediate reboiler E3, and after condensing to a temperature 20°C higher than the reboiler feed temperature of E3, it enters the second condenser and further condenses to 45°C and enters the reflux tank for phase separation, and the water phase is collected. out, part of the toluene liquid is refluxed into the tower, part of it is extracted, and the m...

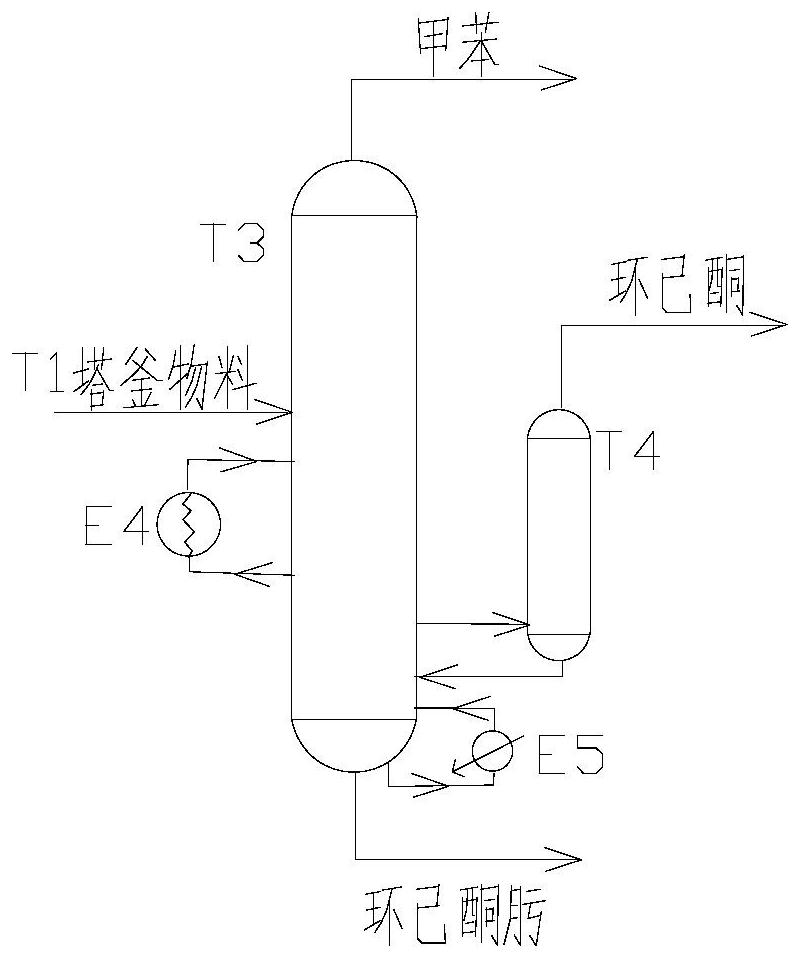

Embodiment 3

[0034] A method for separating cyclohexanone oxime, cyclohexanone and toluene from an ammoximation reaction product. Taking a 100,000-ton / year device as an example, the cyclohexanone oxime content is 24.7%, the toluene content is 73.1%, and the cyclohexanone oxime content is 73.1%. A mixture with a hexanone content of 0.2% and a water content of 2% is added to the pressurized toluene tower T1, the operating pressure of the pressurized toluene tower T1 is 190kpa, the top temperature is 127°C, and 20-30% of toluene and toluene are distilled from the top of the tower. All the moisture in the material, the overhead steam enters the intermediate reboiler E4, and after condensing to a temperature 20°C higher than the reboiler feed temperature of E3, it enters the second condenser and further condenses to 45°C and enters the reflux tank for phase separation, and the water phase is collected. out, part of the toluene liquid is refluxed into the tower, part of it is extracted, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com