Preparation method of high-purity nylon regenerated material

A recycled material, high-purity technology, applied in the field of preparation of high-purity nylon recycled material, to achieve the effect of narrow particle size distribution, high purity, and no impurities in purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

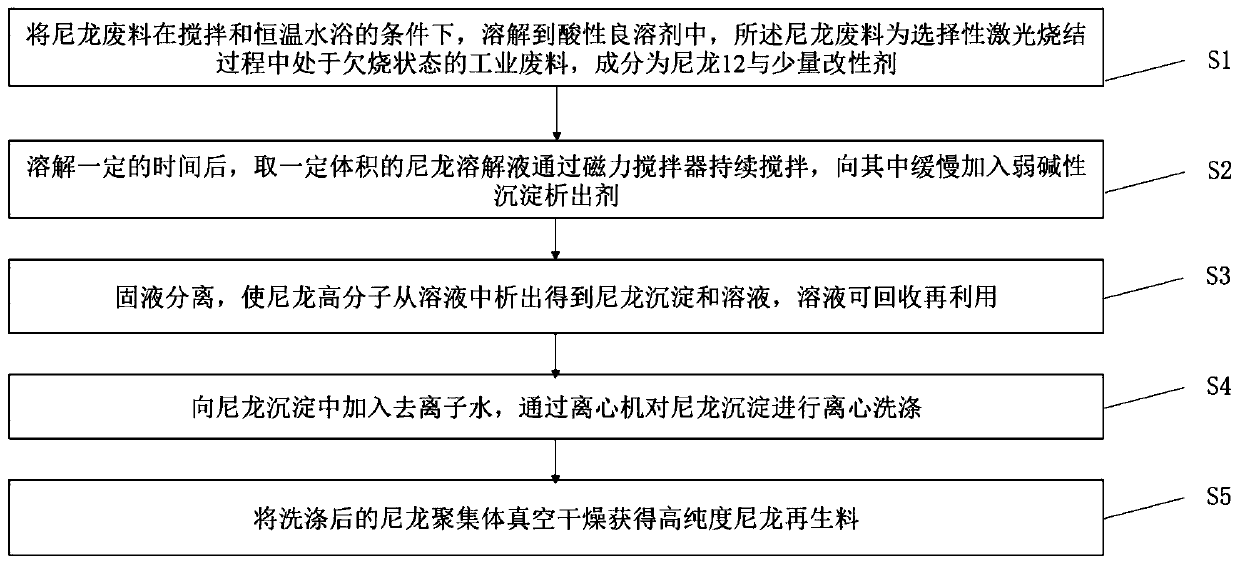

Method used

Image

Examples

Embodiment 1

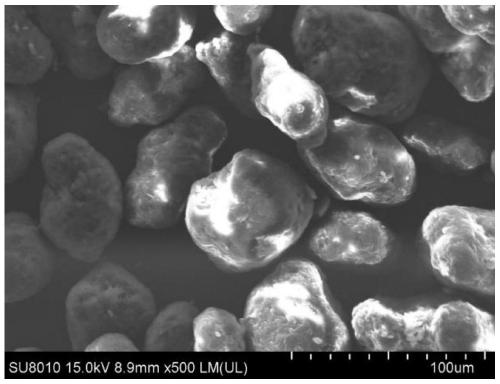

[0029] Dissolve 50g of nylon 12 waste material (95% by weight of nylon 12 and 5% by weight of silica) into 600ml of formic acid solvent under stirring and a constant temperature water bath at 90°C, and stir at constant temperature for 3 hours to fully dissolve the pellets. Take 50ml of the obtained nylon solution, keep stirring and slowly add 300ml of 1% ammonia water to precipitate nylon 12 polymer from the solution, and the stirring speed is 300r / min. After standing for 10 minutes, separate the solid and liquid, recycle the salt solution, add deionized water to the nylon 12 precipitate, wash the nylon 12 precipitate by centrifugation for 5 times, and vacuum dry at 80°C for 10 hours to obtain high-purity nylon 12 Recycled materials. figure 2 The scanning electron micrograph of the nylon 12 recycled material prepared in Example 1.

Embodiment 2

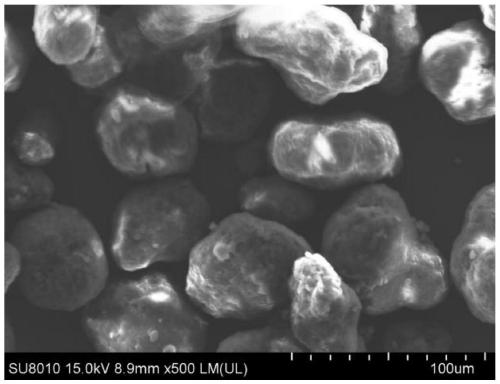

[0031] Dissolve 50g of nylon 12 waste material (95% by weight of nylon 12 and 5% by silicon dioxide) into a mixed solvent of 300ml of formic acid and 300ml of glacial acetic acid under stirring and a 90°C constant temperature water bath, and stir at a constant temperature for 3h to make the particles The material is fully dissolved. Take 50ml of the obtained nylon solution, keep stirring and slowly add 500ml of 2% ammonia water to precipitate the nylon 12 polymer from the solution, and the stirring speed is 300r / min. After standing for 10 minutes, the solid and liquid were separated, and the salt solution was recovered and reused. Deionized water was added to the nylon 12 precipitate, and the nylon 12 precipitate was centrifugally washed 4 times, and vacuum-dried at 80°C for 10 hours to obtain high-purity nylon 12 Recycled materials. image 3 Scanning electron micrograph of the nylon 12 recycled material prepared in Example 2.

Embodiment 3

[0033] Dissolve 50g of nylon 12 waste material (95% by weight of nylon 12 and 5% by silicon dioxide) into a mixed solvent of 400ml formic acid, 100ml glacial acetic acid, and 100ml hydrochloric acid under stirring and a 90°C constant temperature water bath, and stir for 3 hours at a constant temperature , to fully dissolve the pellets. Take 50ml of the obtained nylon solution, keep stirring and slowly add 800ml of 0.2% ammonia water to precipitate nylon 12 polymer from the solution, and the stirring speed is 300r / min. After standing for 10 minutes, separate the solid and liquid, recycle the salt solution, add deionized water to the nylon 12 precipitate, centrifugally wash the nylon 12 precipitate 4 times, and vacuum dry at 80°C for 10 hours to obtain high-purity nylon 12 Recycled materials. Figure 4 Scanning electron micrograph of the nylon 12 recycled material prepared in Example 3.

[0034] Figure 5 The particle size distribution diagram of the nylon 12 recycled materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com