Composite solvent and electrolyte and application of same in lithium-sulfur battery

A composite solvent and lithium-sulfur battery technology, applied in electrolytes, secondary batteries, secondary battery repair/maintenance, etc., can solve problems such as reducing the ionic conductivity of the electrolyte, increasing the cost of the electrolyte, and increasing the viscosity of the electrolyte. Achieve the effect of improving Coulombic efficiency, increasing capacity and cycle stability, and improving the effect of adding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

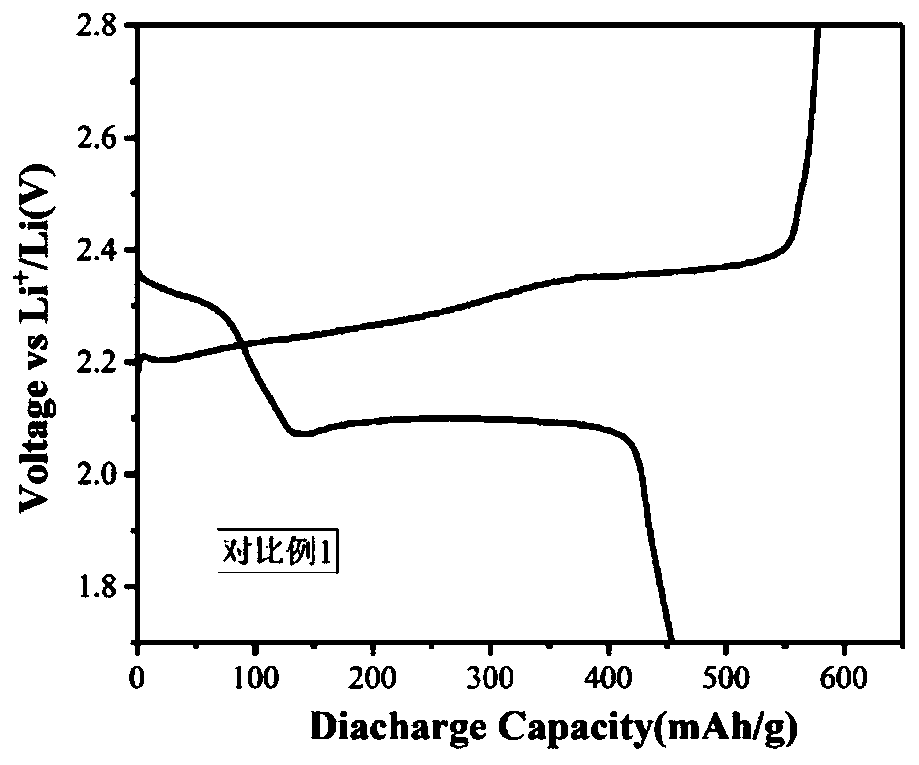

Examples

Embodiment 1

[0047] Prepare the lithium-sulfur battery by configuring the electrolyte as follows:

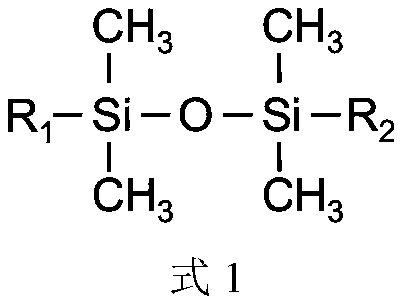

[0048] ①Electrolyte configuration: in a glove box with argon atmosphere (H 2 O1 , R 2 for -(CH 2 ) 2 CH 3 )=45:45:10 mixed with lithium salts LiTFSI (1M) and LiDFOB (0.05M), added anhydrous lithium nitrate with a total mass of 2%, and stirred well to obtain the lithium-sulfur battery electrolyte of the present invention.

[0049] ②Preparation of sulfur positive electrode: mix sulfur / carbon composite material (sulfur load of 80%), acetylene black, and PVDF in a ratio of 80:10:10, and then add an appropriate volume of N-methylpyrrolidone (NMP) Stir in a slurry machine to form a stable and uniform positive electrode slurry. The slurry was coated on a carbon-coated aluminum foil with a doctor blade, and dried in an oven at 80°C for 8 hours until the NMP was completely volatilized.

[0050] ③Lithium-sulfur button battery assembly test: The prepared sulfur pole piece was punched into a Φ13mm...

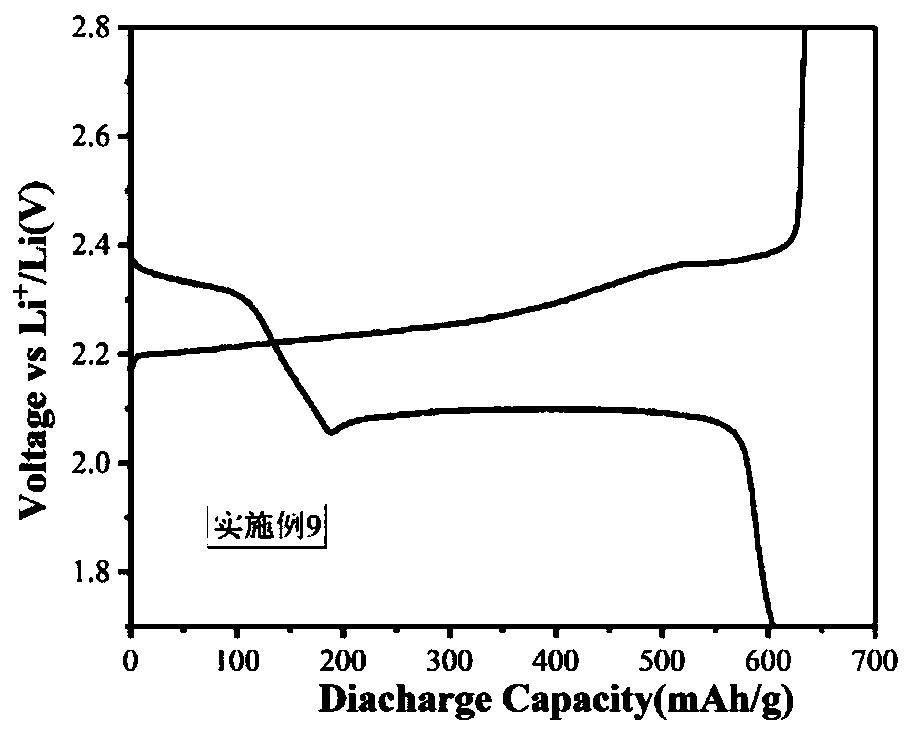

Embodiment 2-4

[0052] Except that the ratio of co-solvent A in Table 1 is changed, other parameters and preparation methods are the same as in Example 1.

Embodiment 2-974

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com