Composite film for agricultural greenhouses and preparation method of composite film

A composite film, agricultural greenhouse technology, applied in the fields of botanical equipment and methods, chemical instruments and methods, agriculture, etc., can solve the problems of limited thermal insulation performance and tensile strength, weak far-infrared blocking ability, serious electrostatic adsorption, etc. The far-infrared blocking ability and thermal insulation performance are improved, the far-infrared blocking ability is strong, and the effect of good resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

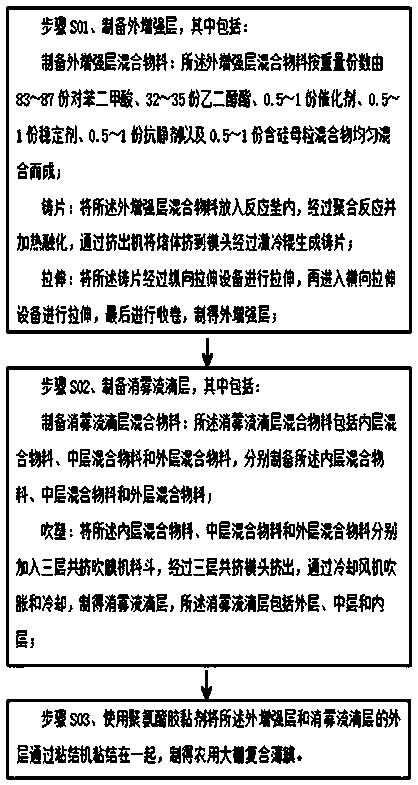

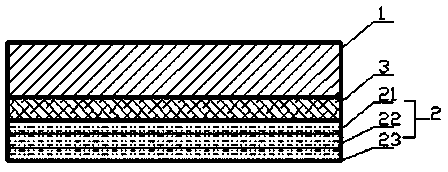

[0031] See figure 1 Shown, the preparation method step of a kind of agricultural greenhouse composite film is as follows:

[0032] Step S01, preparing the outer reinforcing layer 1, which includes:

[0033] Preparation of the external reinforcement layer mixture: the external reinforcement layer mixture consists of 83 parts by weight of terephthalic acid, 32 parts of ethylene glycol ester, 0.9 part of catalyst, 0.7 part of stabilizer, 0.5 part of antistatic agent and 0.5 part of silicon-containing The masterbatch mixture is uniformly mixed;

[0034] Cast sheet: Put the mixed material of the outer reinforcement layer into the reactor, undergo polymerization reaction and heat to melt, extrude the melt to the die head through the extruder and pass through the chilled roll to form the cast sheet;

[0035] Stretching: Stretching the cast sheet through longitudinal stretching equipment, then entering transverse stretching equipment for stretching, and finally winding to obtain the...

Embodiment 2

[0047] See figure 1 Shown, the preparation method step of a kind of agricultural greenhouse composite film is as follows:

[0048] Step S01, preparing the outer reinforcing layer 1, which includes:

[0049] Preparation of the external reinforcement layer mixture: the external reinforcement layer mixture consists of 85 parts by weight of terephthalic acid, 33 parts of ethylene glycol ester, 1 part of catalyst, 0.9 part of stabilizer, 0.7 part of antistatic agent and 0.7 part of silicon-containing The masterbatch mixture is uniformly mixed;

[0050] Cast sheet: Put the reinforced layer mixture into the reactor, undergo polymerization reaction and heat to melt, extrude the melt to the die through the extruder and pass through the chilled roll to form the cast sheet;

[0051] Stretching: Stretching the cast sheet through longitudinal stretching equipment, then entering transverse stretching equipment for stretching, and finally winding to obtain the outer reinforcement layer 1;

...

Embodiment 3

[0063] See figure 1 Shown, the preparation method step of a kind of agricultural greenhouse composite film is as follows:

[0064] Step S01, preparing the outer reinforcing layer 1, which includes:

[0065] Preparation of the external reinforcement layer mixture: the external reinforcement layer mixture consists of 83 parts by weight of terephthalic acid, 32 parts of ethylene glycol ester, 0.9 part of catalyst, 0.7 part of stabilizer, 0.5 part of antistatic agent and 0.5 part of silicon-containing The masterbatch mixture is uniformly mixed;

[0066] Cast sheet: Put the mixed material of the outer reinforcement layer into the reactor, undergo polymerization reaction and heat to melt, extrude the melt to the die head through the extruder and pass through the chilled roll to form the cast sheet;

[0067] Stretching: Stretching the cast sheet through longitudinal stretching equipment, then entering transverse stretching equipment for stretching, and finally winding to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com