Stabilizer composition for quick-frozen meat fillings and preparation method thereof

A technology of stabilizer and composition, applied in the directions of food ingredients as thickeners, food ingredients as antifreeze agents, food ingredients as emulsifiers, etc., can solve the problems of high viscosity of natural colloids, inability to inhibit dehydration and water retention, etc. Achieve strong water retention, reduce oil immersion and increase viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

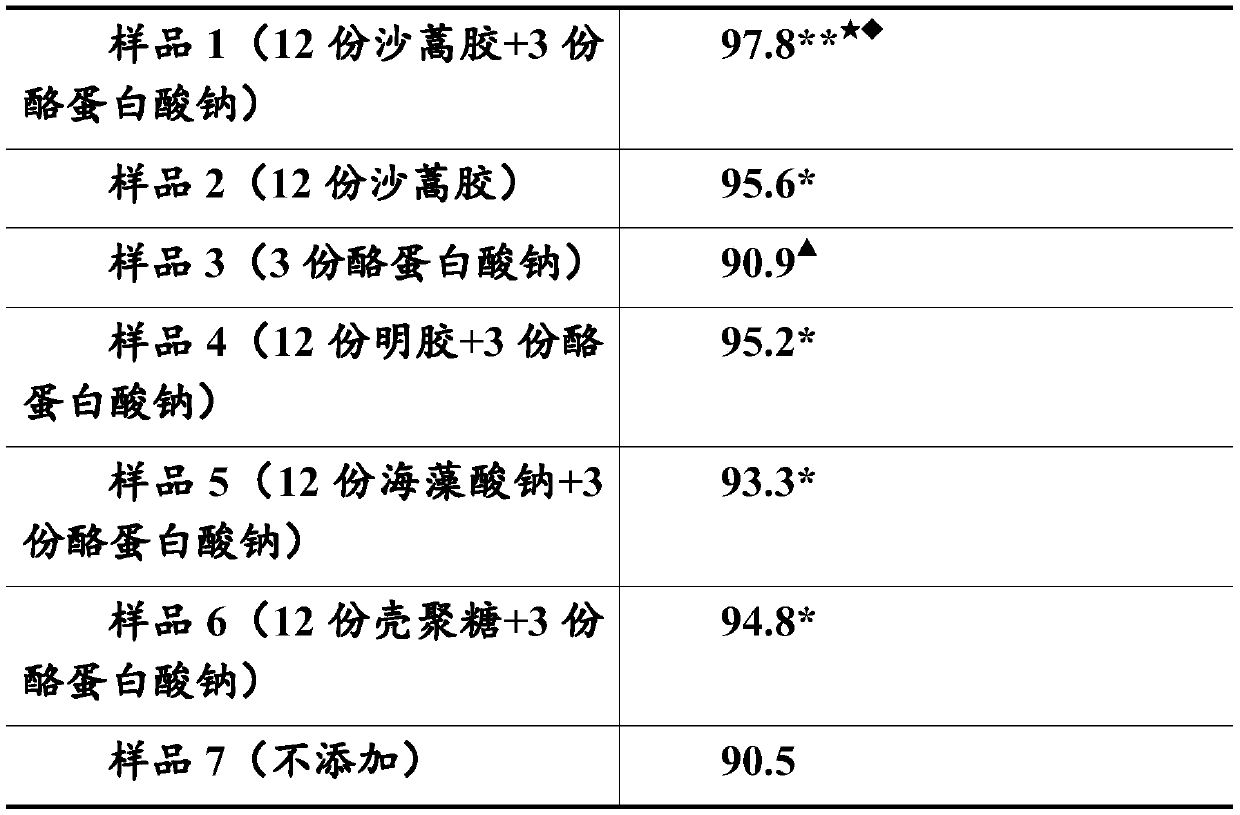

[0028] A quick-frozen meat stuffing food stabilizer, made of the following raw materials in parts by weight: 12 parts of artemisia gum, 3 parts of sodium caseinate, 2 parts of sodium starch octenyl succinate, 2 parts of cholesterol, and 100 parts of water , an appropriate amount of lactic acid, and adjust the pH of the stabilizer to 1.5-5.0.

[0029] The preparation method is as follows: first, mix 100 parts of water with appropriate amount of lactic acid to adjust the pH to 1.5 at 10°C, then add 12 parts of Artemisia gum, 3 parts of sodium caseinate, and 2 parts of sodium starch octenyl succinate to the solution Stir in medium for 15 minutes to make Artemisia gum, sodium caseinate and sodium starch octenyl succinate fully absorb water and swell. Then slowly raise the temperature to 45°C and stir for 20 minutes to completely hydrate the artemisia gum, sodium caseinate and starch sodium octenyl succinate and turn into a clear and transparent solution. Then the solution was fur...

Embodiment 2

[0031] A quick-frozen meat stuffing food stabilizer, which is made of the following raw materials in parts by weight: 10 parts of artemisia gum, 2 parts of sodium caseinate, 2 parts of precrossed starch, 3 parts of cholesterol, 100 parts of water, and an appropriate amount of lactic acid , adjusting the pH of the stabilizer to 1.5-5.0.

[0032] The preparation method is as follows: first, mix 100 parts of water with an appropriate amount of lactic acid to adjust the pH to 1.5 at 10°C, then add 10 parts of artemisia gum, 2 parts of sodium caseinate, and 2 parts of precrossified starch into the solution and stir for 15 Minutes, so that artemisia gum, sodium caseinate and precrossed starch fully absorb water and swell. Slowly raise the temperature to 40°C and stir for 25 minutes to completely hydrate the artemisia gum, sodium caseinate and precrossed starch and turn into a clear and transparent solution. Then the solution was further heated to 70°C, and 2 parts of cholesterol we...

Embodiment 3

[0034] A quick-frozen meat stuffing food stabilizer, made of the following raw materials in parts by weight: 15 parts of artemisia gum, 4 parts of sodium caseinate, 3 parts of cornstarch, 2 parts of cholesterol, 100 parts of water, appropriate amount of lactic acid, adjusted The pH of the stabilizer is 1.5-5.0.

[0035] The preparation method is as follows: first, mix 100 parts of water with an appropriate amount of lactic acid and adjust the pH to 1.5 at 10°C, then add 15 parts of artemisia gum, 4 parts of sodium caseinate, and 3 parts of cornstarch into the solution and stir for 15 minutes. Make artemisia gum, sodium caseinate and cornstarch fully absorb water and swell. Slowly raise the temperature to 50°C and stir for 30 minutes to completely hydrate the artemisia gum, sodium caseinate and cornstarch and turn into a clear and transparent solution. Then the solution was further heated to 80°C, and 2 parts of cholesterol were added, stirred evenly, and the pH value was adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com