Magnetic catalyst, preparation method thereof, and method for preparing furfuryl alcohol

A magnetic catalyst, furfuryl alcohol technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of unfavorable catalyst environment, difficulty in balancing catalytic activity and reusability etc. to achieve good reusability, high catalytic activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

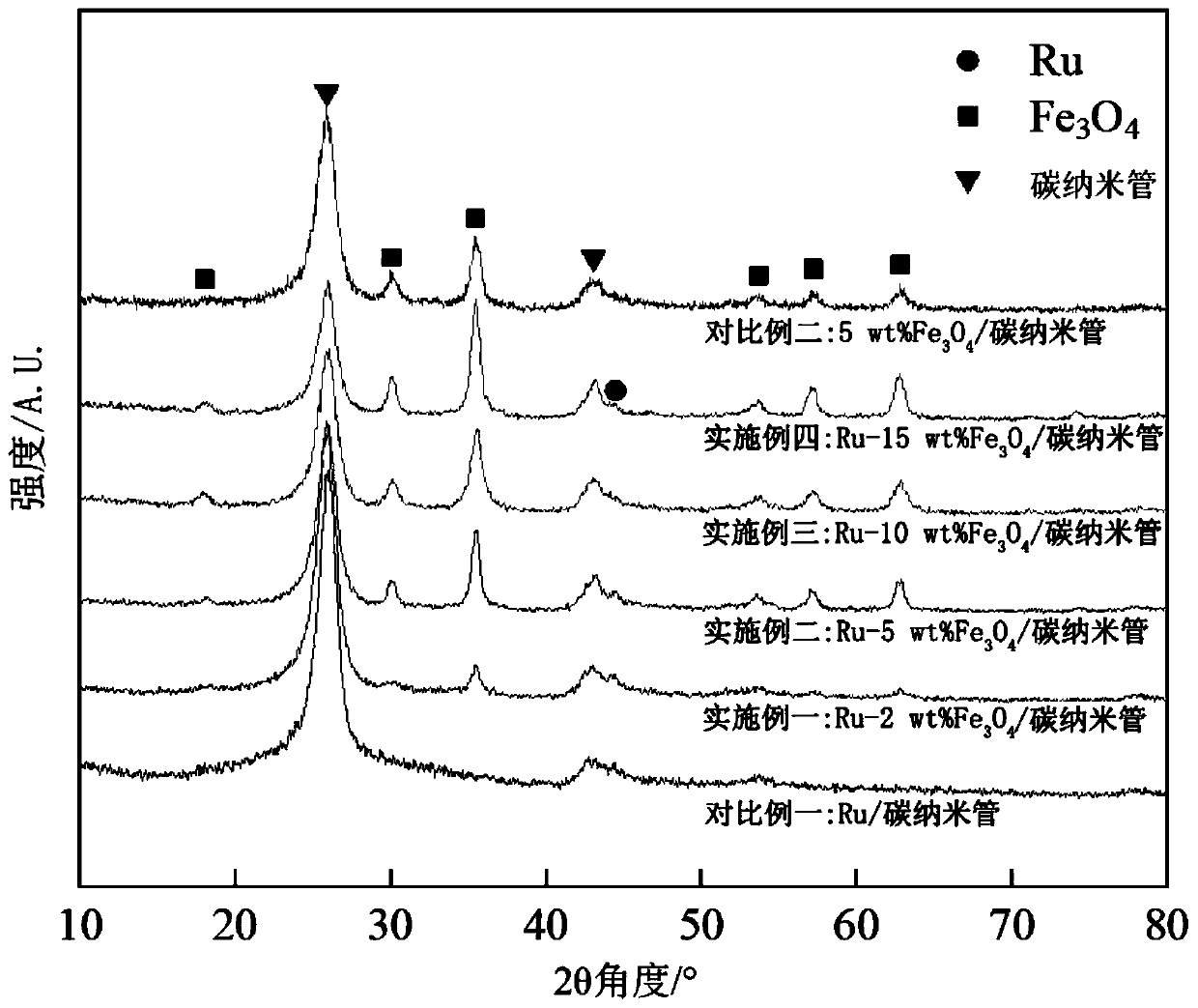

[0030] This embodiment provides a magnetic catalyst, and the preparation method of the magnetic catalyst comprises the following steps:

[0031] To treat carbon nanotubes, put 1g of carbon nanotubes in 75mL of concentrated sulfuric acid with a mass percentage of 70%, ultrasonically disperse at 30°C for 0.5h, then add 25mL of concentrated nitric acid with a mass percentage of 68% to form a mixed acid, continue Ultrasonic disperse for 0.5h, then heat up to 120°C and reflux for 6h, filter with a 0.45μm microporous membrane after cooling, wash the filtered carbon nanotubes with deionized water until the pH of the filtrate is neutral, and wash the carbon nanotubes The tubes were dried at 100°C to obtain acid-treated carbon nanotubes. Summary of this embodiment, the volume ratio of concentrated sulfuric acid and concentrated nitric acid is 3:1, and every 100 mL of the mixed acid of concentrated sulfuric acid and concentrated nitric acid is used to treat 1 g of carbon nanotubes.

[...

Embodiment 2

[0036] The difference between this example and Example 1 is that in the reaction step, 0.088g of ferric chloride hexahydrate is weighed, and 0.450g of acid-treated carbon nanotubes are added to the aqueous solution of ferric chloride for treatment to obtain A magnetic catalyst with a ruthenium loading of 5wt% and a ferric oxide loading of 5wt% is designated as R2.

Embodiment 3

[0038] The difference between this example and Example 1 is that in the reaction step, 0.175g of ferric chloride hexahydrate is weighed, and 0.425g of acid-treated carbon nanotubes are added to the aqueous solution of ferric chloride for treatment to obtain A magnetic catalyst with a ruthenium loading of 5wt% and a ferric oxide loading of 10wt% is coded as R3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com