Water glass inorganic used sand regeneration method

A technology of used sand regeneration and water glass, which is applied in the cleaning/processing machinery of casting materials, casting molding equipment, casting molds, etc., can solve the problems of shortening the life of regeneration equipment, poor quality of recycled sand and low regeneration efficiency, Achieve the effect of acid-base stability, high regeneration rate and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of water glass inorganic old sand regeneration method, comprises the following steps:

[0038] (1) Add 1 part by weight of additives to 100 parts by weight of water glass inorganic old sand and stir and mix. The additives contain aluminum chloride, ammonium chloride and silicon dioxide, and the mass ratio of the three is 2:2:1 .

[0039] During the stirring process, 0.5 parts by weight of water was added by spraying, and stirred for 5 minutes to obtain a mixture.

[0040] (2) After the stirring is completed, the mixture is placed in a centrifuge at a centrifugal speed of 500-3000 r / min, and centrifuged continuously for 1 min to obtain regenerated sand.

[0041] (3) The recycled sand after centrifugation is sieved through a 140-mesh screen and recorded as finished sand.

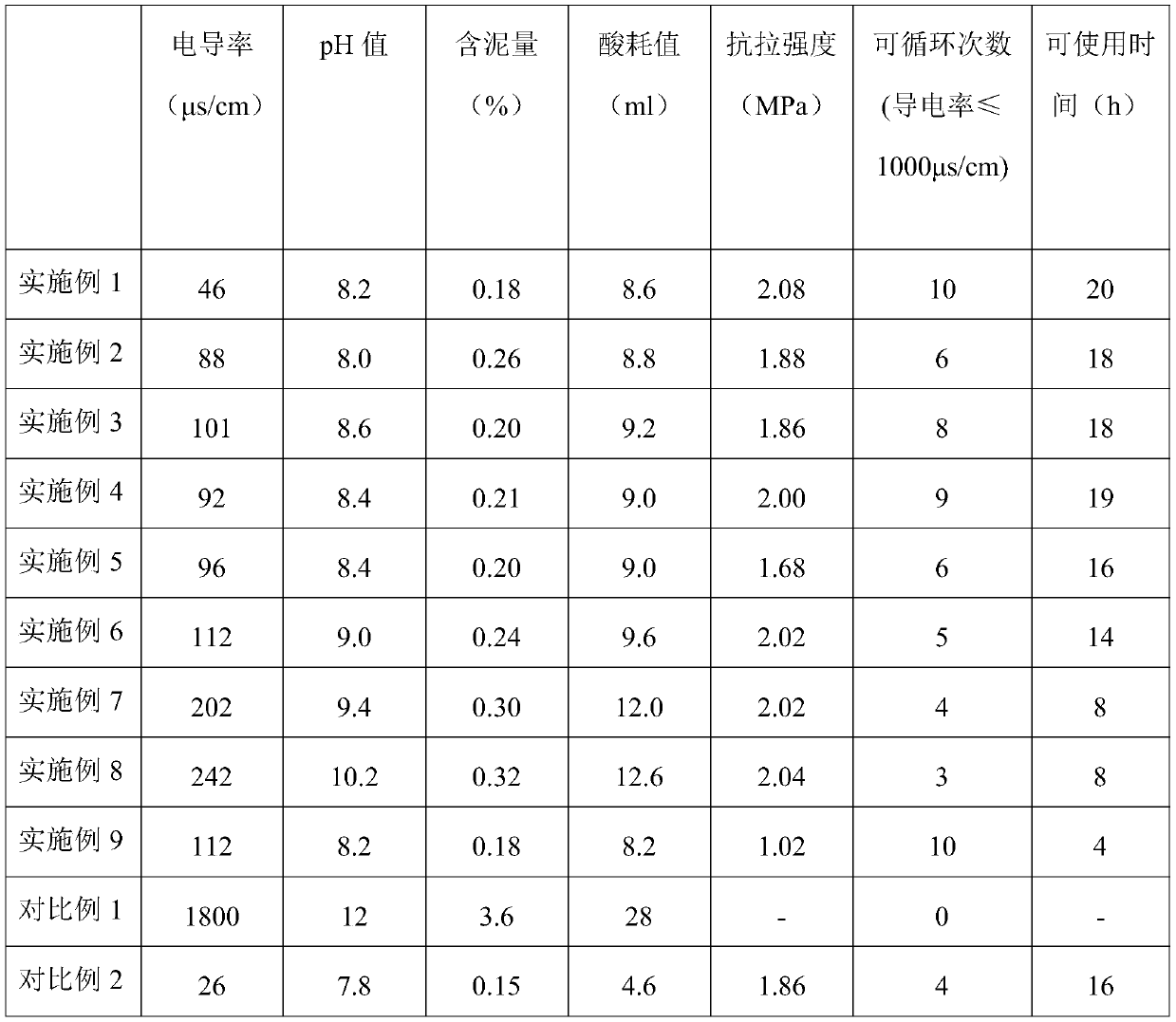

[0042] The reaction conditions in Examples 2-9 were changed, and the specific settings are shown in Table 1. The properties of the reclaimed sand obtained are shown in Table 2.

[0043] Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com