Tire sidewall rubber composition capable of resisting early wax spraying in high-damp-heat environment and preparation method of tire sidewall rubber composition

A hot and humid environment, sidewall rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve the problems of early blooming, reduce whitening of blooming, improve anti-blooming performance, prevent anti-aging The effect of performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

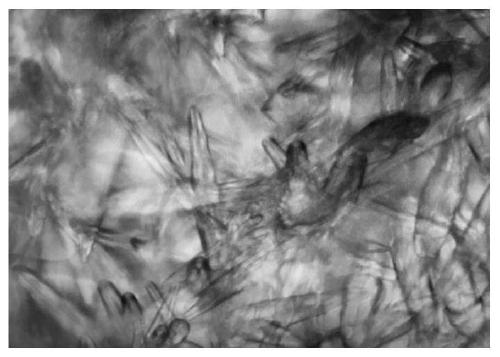

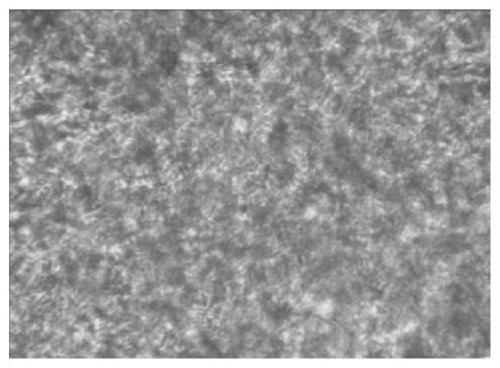

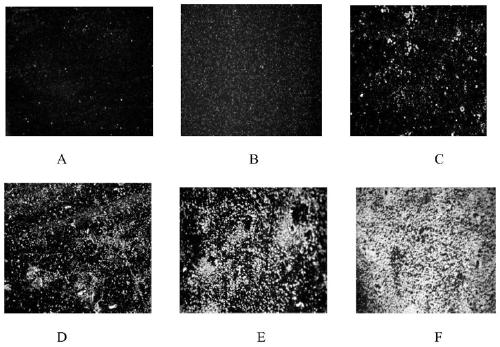

Image

Examples

Embodiment 1

[0032] One-stage mastication: add all the natural rubber, butadiene rubber and 1 / 2-2 / 3 carbon black into the internal mixer, press the top bolt and knead for 30 seconds, raise the top bolt, press the lump and knead for 25 seconds, and then lift Clean the top bolt, press the top bolt and mix for 25s, open the discharge door to remove glue, control the glue removal temperature to 140°C, the speed of the internal mixer is 50 rpm, open the mixer to unload, cool and build, and get a stage of mixing glue;

[0033]Two-stage mixing: add the obtained first-stage plasticizing rubber, all remaining carbon black, and all tackifying resins, stearic acid, zinc oxide, environmentally friendly aromatic oil, modified protective wax, anti-aging agent RD and anti-aging agent 4020 In the internal mixer, press the top bolt to mix for 40 seconds, raise the top bolt to clean for 5 seconds, press the top bolt to mix for 30 seconds, open the discharge door to discharge glue, control the glue discharge...

Embodiment 2

[0037] One-stage mastication: add all the natural rubber, butadiene rubber and 1 / 2-2 / 3 carbon black into the internal mixer, press the top bolt and knead for 25 seconds, raise the top bolt, press the lump and knead for 20 seconds, lift Clean the top bolt, press the top bolt and mix for 20s, open the discharge door to remove the glue, control the glue removal temperature to 135°C, the speed of the internal mixer is 40 rpm, open the mixer to unload, cool and build, and get a stage of mixing glue;

[0038] Two-stage mixing: add the obtained first-stage plasticizing rubber, all remaining carbon black, and all tackifying resins, stearic acid, zinc oxide, environmentally friendly aromatic oil, modified protective wax, anti-aging agent RD and anti-aging agent 4020 In the internal mixer, press the top bolt to mix for 35 seconds, raise the top bolt to clean for 5 seconds, press the top bolt to mix for 25 seconds, open the discharge door to discharge glue, control the glue discharge tem...

Embodiment 3

[0042] One-stage mastication: add all the natural rubber, butadiene rubber and 1 / 2-2 / 3 carbon black into the internal mixer, press the top bolt and knead for 35 seconds, raise the top bolt, press the lump and knead for 30 seconds, and then lift Clean the top bolt, press the top bolt and mix for 30s, open the discharge door to remove glue, control the glue removal temperature to 145°C, the speed of the internal mixer is 60 rpm, open the mixer to unload, cool and build, and get a stage of mixing glue;

[0043] Two-stage mixing: add the obtained first-stage plasticizing rubber, all remaining carbon black, and all tackifying resins, stearic acid, zinc oxide, environmentally friendly aromatic oil, modified protective wax, anti-aging agent RD and anti-aging agent 4020 In the internal mixer, press the top bolt to mix for 45 seconds, raise the top bolt to clean for 5 seconds, press the top bolt to mix for 35 seconds, open the discharge door to discharge glue, control the glue discharg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com