Long-afterglow PE (polyethylene) master batch and preparation method thereof, PE plastic part and preparation method thereof

A long afterglow, masterbatch technology, applied in its preparation, PE plastic parts and its preparation, long afterglow PE masterbatch field, can solve the problems of uneven dispersion of luminous powder, reduced mechanical properties, low content of luminous powder, etc. Improve compatibility, reduce the effect of masterbatch color darkening and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

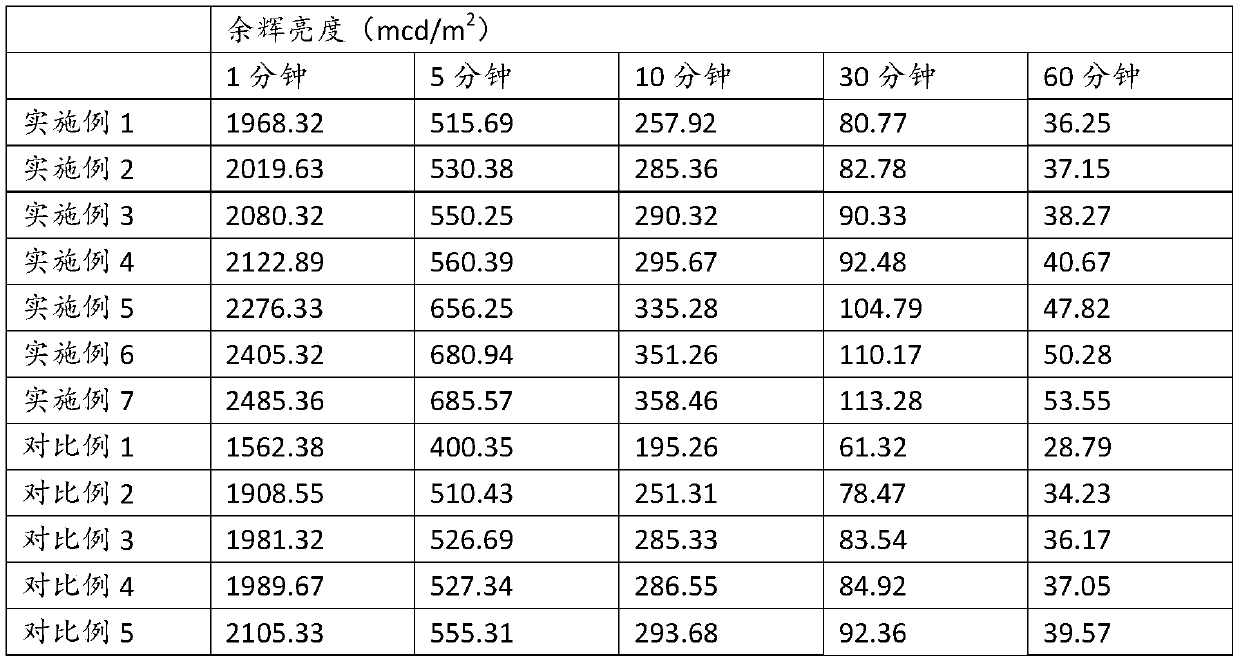

Examples

preparation example Construction

[0047] The preparation of the graft polymer is a routine experiment for those skilled in the art, and will not be described in detail in the present invention.

[0048] Further, the above-mentioned dispersant is a hyperbranched polymer. For example, at least one of C100, C181, HyPerC10, HyPerC20, HyPerC30 and HyPerC40 produced by Guangdong Fujiang Chemical Reagent Co., Ltd. can be used. The use of the above-mentioned dispersant can further promote the uniform mixing of the luminous powder and the PE resin, prevent the aggregation of the luminous powder, and reduce the aging of the PE resin, thereby ensuring the luminous effect of the long-lasting PE masterbatch.

[0049] Further, the heat stabilizer is a stearic acid compound, preferably a stearate, more preferably zinc stearate or calcium stearate, the use of the above heat stabilizer can further reduce the aging of the PE resin during the preparation process, ensuring Long afterglow PE masterbatch has bright luminous color,...

Embodiment 1

[0064] This embodiment provides a long afterglow PE masterbatch, the composition of raw materials is as follows, 68.5g of PE-MAH (maleic anhydride modified polyethylene, grafting rate of 0.5%), 0.5g of C100 dispersant, 1g of Zinc Stearate, 30g of BL-2A Luminous Powder.

[0065] This embodiment also provides a preparation method of long afterglow PE masterbatch:

[0066] Add each component to the mixer and mix for 3 minutes in a mixer with a rotation speed of 100r / min. After mixing evenly, add it to a twin-screw extruder with a rotation speed of 200r / min, and melt at 140°C After blending and extruding, it is granulated, then dried, and packaged to obtain long-lasting PE masterbatch.

Embodiment 2

[0068] This embodiment provides a long afterglow PE masterbatch, the composition of raw materials is as follows, 64gPE-MAH (grafting rate 0.5%), 1gC181 hyperdispersant, 5g calcium stearate, 30g of GL-8C luminous powder.

[0069] This embodiment also provides a preparation method of long afterglow PE masterbatch:

[0070] Add each component to the mixer and mix for 10 minutes in a mixer with a rotation speed of 200r / min. After mixing evenly, add it to a twin-screw extruder with a rotation speed of 500r / min and melt it at a temperature of 150°C. After blending and extruding, it is granulated, then dried, and packaged to obtain long-lasting PE masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com