High-decorative acrylic polysiloxane coating and preparation method thereof

A technology of acrylic polysiloxane and acrylic polymer, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of glossiness, smoothness, fullness, artificial aging, poor decoration, etc., and achieve great economic value And environmental protection value, high fullness, good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

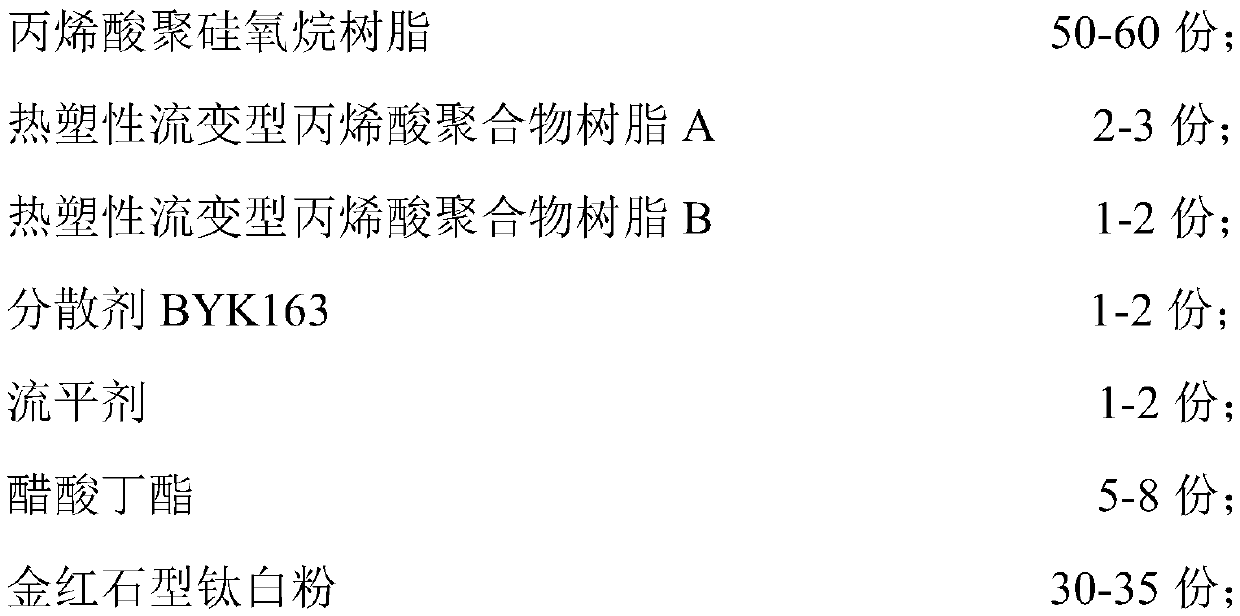

[0032] The preparation method of high decorative acrylic polysiloxane coating of the present invention, comprises the following steps:

[0033] 1) Preparation of rheological oligomers:

[0034] Take 18-23 parts of dimethylamine and 13-16 parts of formaldehyde and put them in a three-necked flask. After the reaction is complete for about 1 hour, add 50-60 parts of nonionic polyacrylamide to the amine methylation reaction system. After reacting at ~50°C for 3-4 hours, slowly add 9-11 parts of dimethyl sulfate for quaternization treatment, react for 1 hour and then cool to room temperature. The product is an aqueous solution, which is evaporated and dried into a solid powder, and then the powdered oligomer is dissolved into a solution with a mass fraction of 25% by using xylene, which is a rheological oligomer.

[0035] 2) Preparation of thermoplastic rheological acrylic resin A:

[0036] Put 30-35 parts of rheological oligomer, 4-6 parts of butyl acrylate, 8-10 parts of methyl...

Embodiment 1

[0044] Step 1, prepare rheological oligomer, it comprises following reaction process:

[0045] Take 18 parts of dimethylamine and 13 parts of formaldehyde in a three-necked flask. After the reaction is complete for about 1 hour, add 60 parts of nonionic polyacrylamide to the amine methylation reaction system, and react at 45°C for 4 hours. Then slowly add 9 parts of dimethyl sulfate for quaternization treatment, react for 1 hour and then cool to room temperature. The product is an aqueous solution, which is evaporated and dried into a solid powder, and then the powdered oligomer is dissolved into a solution with a mass fraction of 25% by using xylene, which is a rheological oligomer. Its reaction equation is:

[0046]

[0047] Step 2, preparing thermoplastic rheological type acrylic polymer resin A, the required raw materials and quantity ratio are as follows:

[0048]

[0049] Polymerization process:

[0050] The rheological oligomer, butyl acrylate, methyl methacrylat...

Embodiment 2

[0060] Step 1, prepare rheological oligomer, it comprises following reaction process:

[0061] Take 23 parts of dimethylamine and 16 parts of formaldehyde in a three-necked flask. After the reaction is complete for about 1 hour, add 50 parts of nonionic polyacrylamide to the amine methylation reaction system, and react at 50°C for 3 hours. Then slowly add 11 parts of dimethyl sulfate for quaternization treatment, react for 1 hour and then cool to room temperature. The product is an aqueous solution, which is evaporated and dried into a solid powder, and then the powdery oligomer is dissolved into a solution with a mass fraction of 25% using xylene, which is a rheological oligomer;

[0062] Step 2, preparing thermoplastic rheological type acrylic polymer resin A, the required raw materials and quantity ratio are as follows:

[0063]

[0064] The raw materials of above-mentioned proportioning are made thermoplastic rheological type acrylic resin A cooling filter packaging ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com