Fuel for catering stove and preparation method of fuel

A furnace fuel and catering technology, applied in the field of catering furnace fuel and its preparation, can solve the problems of methanol toxicity, high fire safety pressure, rapid explosion, etc., to reduce maintenance times, improve combustion performance, and improve calorific value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Fuel for catering stoves in the present invention comprises the following compositions according to weight percentage: Fischer-Tropsch synthetic wax (C12~C18) 20%, refined waste oil 50%, biodiesel 25%, polyoxymethylene dimethyl ether (CH 3 O-(CH 2 O)n-CH 3 , n=2~5) 5%.

[0020] The preparation steps of fuel for above-mentioned catering stove among the present invention are:

[0021] S1. Add the above components into the stirring tank, and stir evenly at room temperature to obtain a semi-finished product;

[0022] S2. The semi-finished product is subjected to circular sand filtration with a sand filter tank until the oil product is clear and transparent, and the product is obtained by discharging.

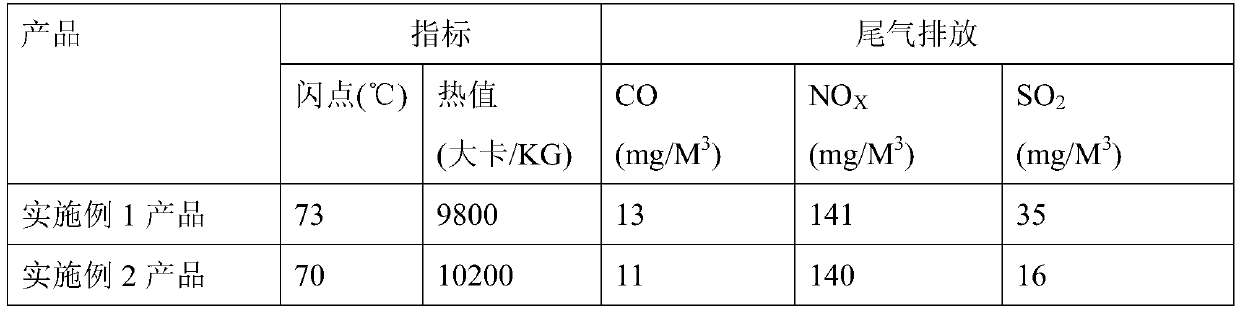

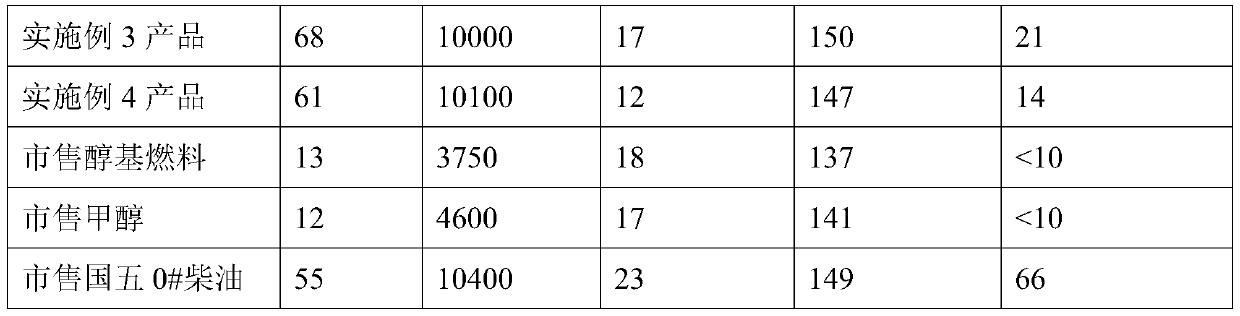

[0023] Product performance testing and combustion experiments on catering stoves, the results are shown in Table 1 below.

Embodiment 2

[0025] Fuel for catering stoves in the present invention comprises the following compositions according to weight percentage: Fischer-Tropsch synthetic wax (C12~C18) 40%, refined waste oil 30%, biodiesel 20%, polyoxymethylene dimethyl ether (CH 3 O-(CH 2 O)n-CH 3 , n=2~5) 10%.

[0026] The preparation steps of fuel for above-mentioned catering stove among the present invention are:

[0027] S1. Add the above components into the stirring tank, and stir evenly at room temperature to obtain a semi-finished product;

[0028] S2. The semi-finished product is subjected to circular sand filtration with a sand filter tank until the oil product is clear and transparent, and the product is obtained by discharging.

[0029] Product performance testing and combustion experiments on catering stoves, the results are shown in Table 1 below.

Embodiment 3

[0031] Fuel for catering stoves in the present invention comprises the following compositions according to weight percentage: 30% of Fischer-Tropsch synthetic wax (C12~C14), 50% of refined hog oil, 15% of biodiesel, polyoxymethylene dimethyl ether (CH 3 O-(CH 2 O)n-CH 3 , n=3~5) 5%.

[0032] The preparation steps of fuel for above-mentioned catering stove among the present invention are:

[0033] S1. Add the above components into the stirring tank, and stir evenly at room temperature to obtain a semi-finished product;

[0034] S2. The semi-finished product is subjected to circular sand filtration with a sand filter tank until the oil product is clear and transparent, and the product is obtained by discharging.

[0035] Product performance testing and combustion experiments on catering stoves, the results are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com