A waste combustion furnace with heat flow organization

A combustion furnace and waste technology, applied in the direction of combustion type, combustion method, incinerator, etc., can solve the problems of secondary pyrolysis carbon black that is difficult to burn out, impact, and excessive emissions, so as to avoid flue gas denitrification, ensure stable combustion, combustion stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

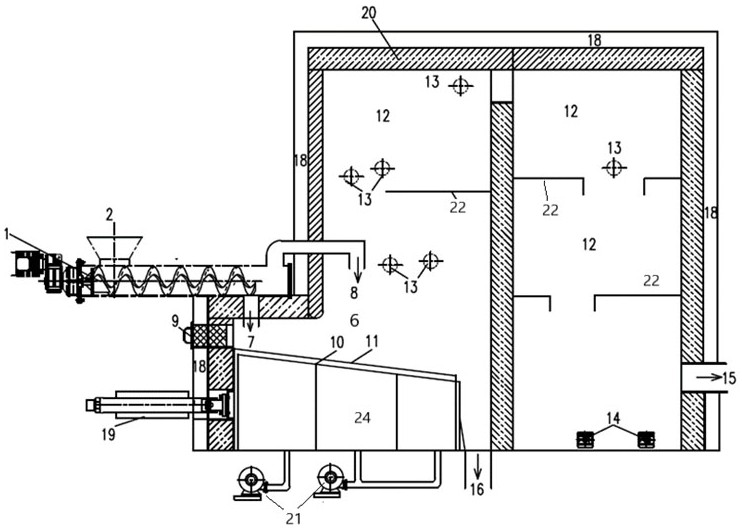

[0039] like figure 1 The illuminated waste combustion furnace having a heat flow tissue includes a cavity channel 1, a waste entrance hopper 2, an outer heat chamber 4, a combustion chamber 6, a pyrolysis carbon 7 transport channel, and the conveying passage of a combustion chamber 6, a pyrolysis carbon 7 Channel, furnace door 9, fixed furnace row 10, dynamic furnace row 11, two diverse chamber 12, air supply port 13, clear gray 14, flue gas outlet 15, slaushed port 16, insulation layer 18, drive mechanism 19, furnace wall 20, fan 21, the baffle wall 22 and the wind bun 24.

[0040] The cavity channel having a heat-flow tissue, a cavity channel 1 of transporting waste and a pyrolysis waste is selected from the group consisting of a shaft double helix or a sleeve of a sleeve of the outer heat chamber 4, and there is a waste in the inner side of the shaft double helix or the inner side of the rotor. The outer side has high temperature thermal flue gas, separated by metal walls in th...

Embodiment 2

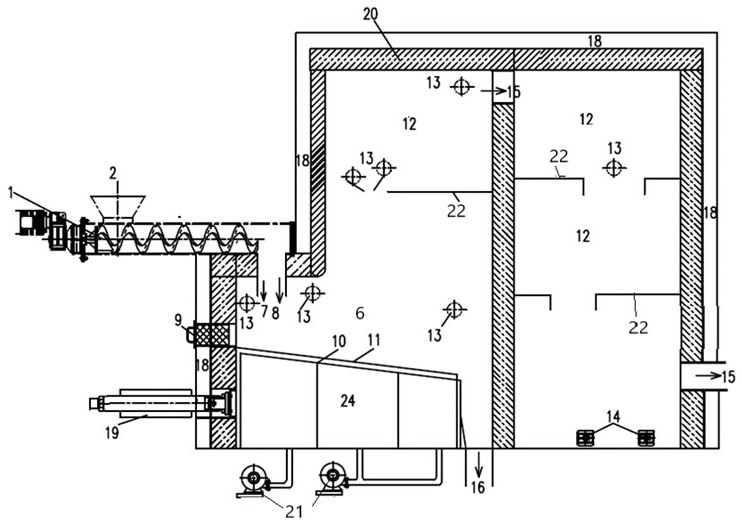

[0048] like figure 2 The illuminated waste combustion furnace is shown, including the transport of waste and waste pyrolysis, the waste entrance hopper 2, the outer heat chamber 4, the combustion chamber 6, the delivery channel of the pyroelectric carbon 7, and the conveying of the passage 8 Channel, furnace door 9, fixed furnace row 10, dynamic furnace row 11, two diverse chamber 12, air supply port 13, clear gray 14, flue gas outlet 15, slaushed port 16, insulation layer 18, drive mechanism 19, furnace wall 20, fan 21, the baffle wall 22 and the wind bun 24. The pyrolytic carbon 7 and the conveying channel of the volatilizing portion fall together on the stove.

[0049] The heat-fluvous waste combustion furnace, the transporting waste and the waste-free cavity channel 1 is selected from the group consisting of a shaft double helix or with any of the sleeve cartridges of the outer heat chamber 4, and the waste side is transported while being picked. The thermally desolation cavit...

Embodiment 3

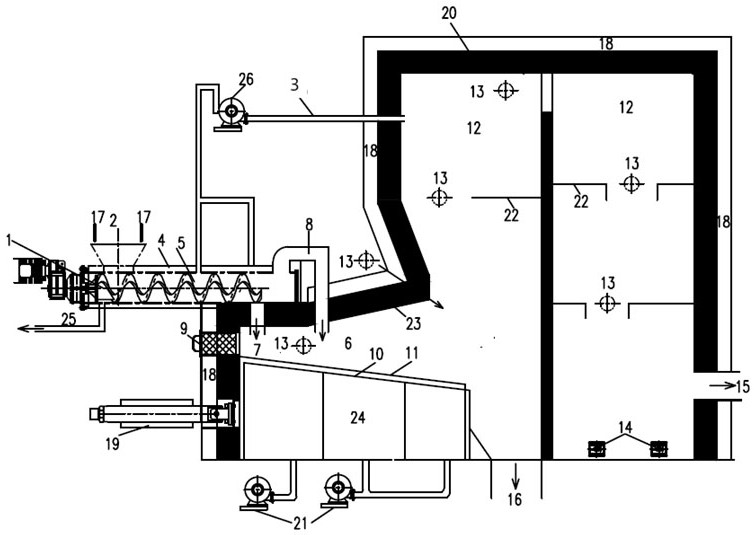

[0058] The waste residue of a paper mill, a water containing 35-38%, the heat value of 11.5-13 mJ / kg, the amount of treatment is 25 t / d, after breaking, image 3 The illustrated waste combustion furnace with thermal organisms, transporting waste and pyrolysis waste is selected from the prevision of spaced rotary kiln in the prior art, and the outer side of the rotary cylinder has an external heat of the waste heat. Room 4, the high temperature flue gas inlet 5 supplied from the high temperature flue gas circulating fan 26, the high temperature flue gas 3 is entered by high temperature flue gas inlet 5, and its cycle amount is guaranteed in the range of 500-650 ° C. The evaporation and export of moisture can be used in prior art, such as the collection technique of dry moisture in patented ZL201410305784.9. Wastes becomes two heat flows in the cavity passage 1 of transport waste and pyrolysis waste: pyrolyzed carbon 7 and volatilization 8. The thermal decomposer 7 is falling on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com