Method for preparing integrated quasi-solid zinc ion battery

A zinc-ion battery, quasi-solid-state technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of low theoretical capacity zinc negative electrode capacity, reduced utilization rate of positive electrode materials, and shedding of positive electrode materials, so as to save production costs and Effects of production time, increase in volume specific energy, and increase in area specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

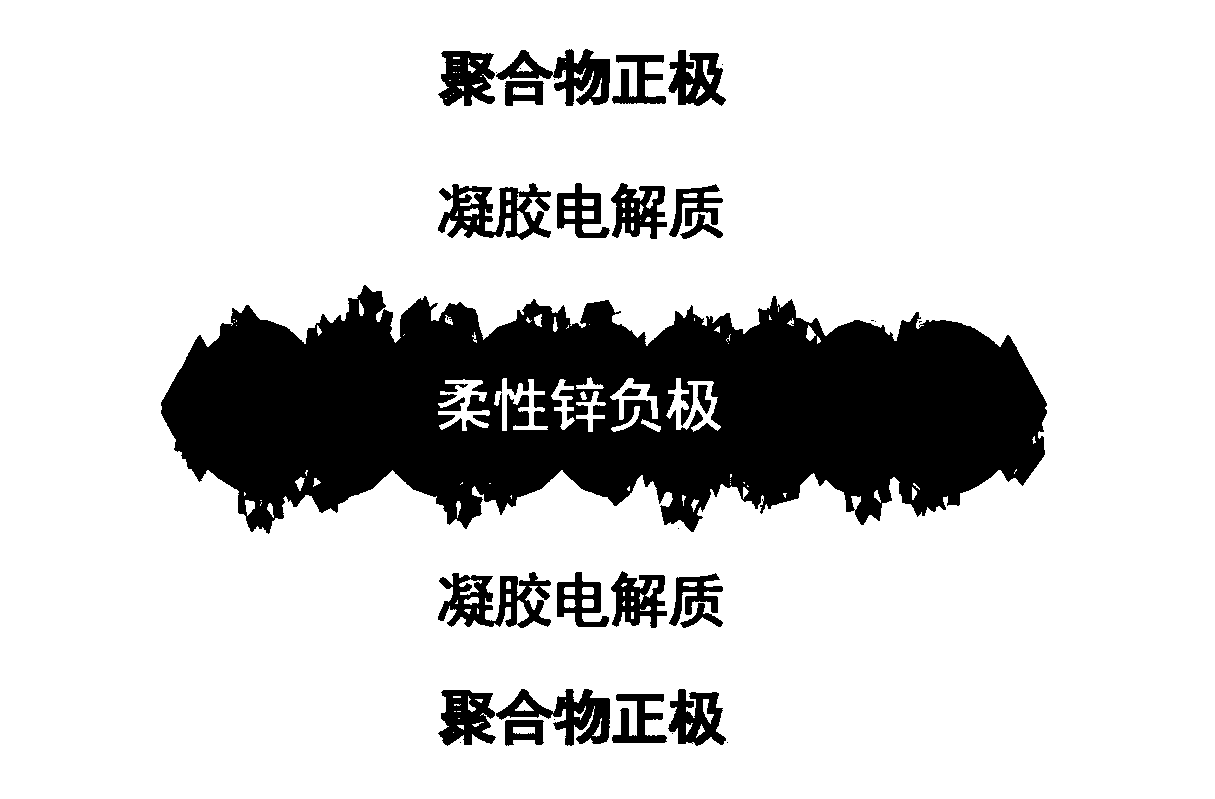

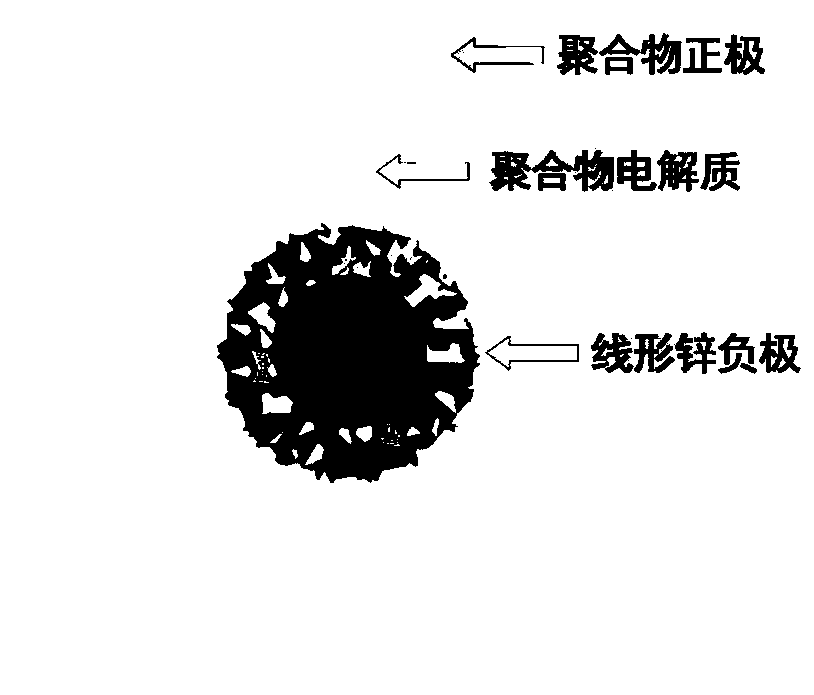

[0022] Embodiment 1: An integrated quasi-solid-state zinc-ion battery, the preparation of the zinc-ion battery is based on a hydrogel electrolyte, the negative electrode of the battery is embedded in the middle of the gel electrolyte matrix, and the outer surface of the gel electrolyte is polymerized A layer of polymer is the positive electrode of the battery.

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment differs from Embodiment 1 in that: the hydrogel is polyacrylamide, polyacrylic acid, polyvinyl alcohol and a mixture of one or more of them. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment is different from Embodiment 1 in that: the electrolyte is zinc sulfate, zinc chloride or zinc trifluoromethanesulfonate. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com