System and method for biological treatment of high-salt high-organic matter industrial wastewater

A technology for industrial wastewater and biological treatment, applied in the direction of biological treatment devices, sustainable biological treatment, biological water/sewage treatment, etc. The effect of manpower investment, good treatment and stable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

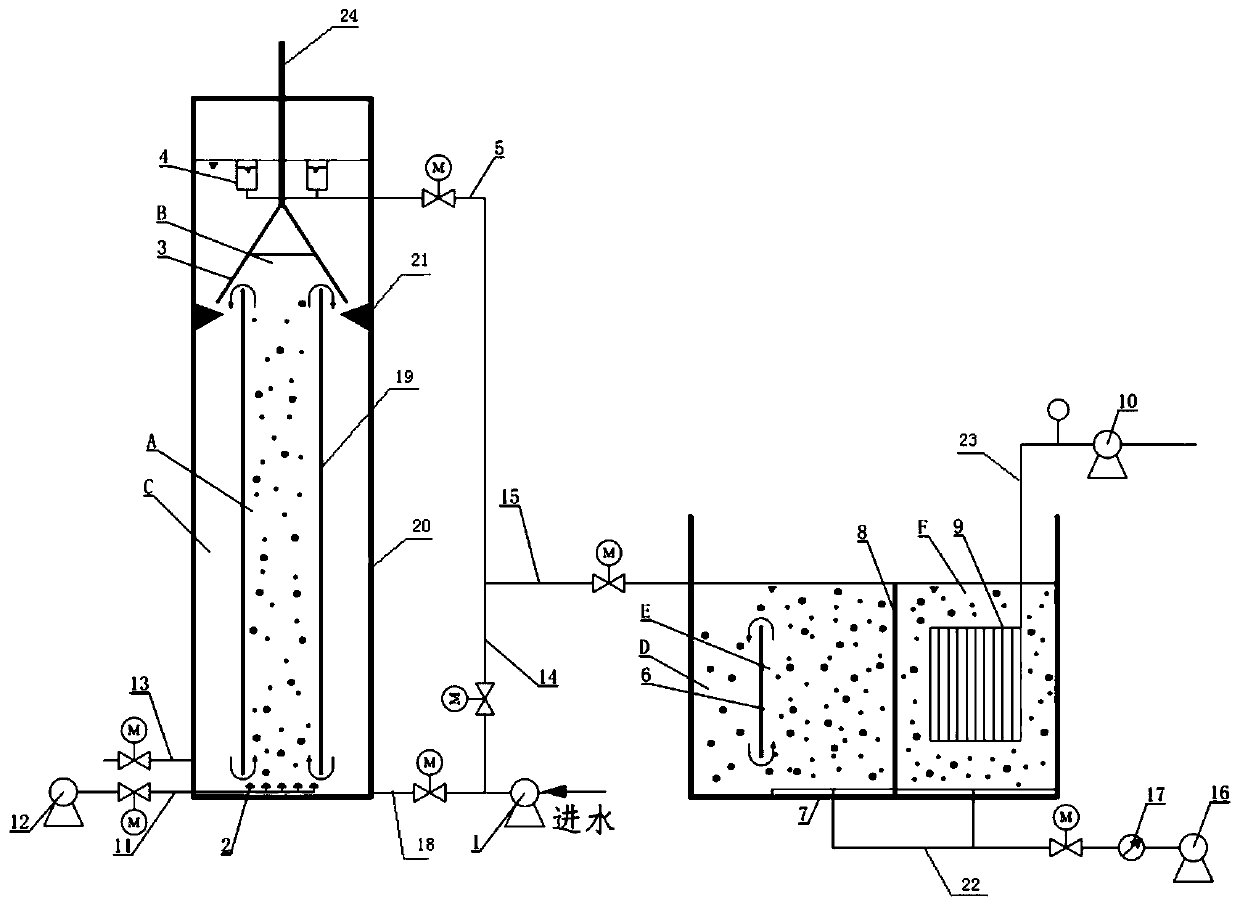

[0041] A biological treatment system for high-salt and high-organic industrial wastewater is characterized in that it mainly includes an internal circulation aerobic granular sludge reactor, an integrated aerobic granular sludge membrane bioreactor, and a piping system.

[0042] The height-to-diameter ratio of the outer cylinder of the internal circulation aerobic granular sludge reactor is 4-12. . The bottom of the internal circulation aerobic granular sludge reactor is connected to the water inlet pipe I18, the aeration pipe I11 and the sludge outlet pipe 13. The water inlet pipe I18 is used to pump waste water through the water inlet pump 1 . The sludge outlet pipe 13 is used to discharge the sludge at the bottom of the reactor.

[0043] An overflow weir is installed at the top of the internal circulation aerobic granular sludge reactor to discharge water. That is, the water overflowing from the top enters the sump 4 . Below the sump 4 are three-phase separator 3 , inne...

Embodiment 2

[0051] This embodiment provides a method for biological treatment of high-salt and high-organic industrial wastewater based on the system described in Embodiment 1, which is characterized in that it comprises the following steps:

[0052] 1) Inlet pump 1 continuously sends high-salt and high-organic industrial wastewater into the bottom of the aerobic granular sludge reactor. It is worth noting that after the system circulates, in step 1), the water inlet pump 1 continuously sends the high-salt and high-organic industrial wastewater into the bottom of the aerobic granular sludge reactor, and mixes it with the return water in the circulation zone C. The particle size of the aerobic granular sludge inside the aerobic granular sludge reactor is 800-2000 μm, and the total amount of the aerobic granular sludge is kept above 80% of the total amount of sludge in the reactor. The inoculated sludge needs 3-15 days of aeration, high influent load and high salt pre-cultivation. After a l...

Embodiment 3

[0067] This embodiment is based on the method disclosed in embodiment 2, comprising the following steps:

[0068] The return sludge from the secondary sedimentation tank of a sewage treatment plant in Chongqing was taken, and after 10 days of aeration and high influent load pre-cultivation, after a large number of filamentous bacteria were produced, it was inoculated into the internal circulation aerobic granular sludge reactor and integrated aerobic granule Sludge membrane bioreactor. The influent water is the distribution water of Fuling shale gas wastewater, its COD is 2000mg / L, and the TDS concentration is 30000mg / L.

[0069] The height-to-diameter ratio of the internal circulation aerobic granular sludge reactor is 4, the diameter is 0.8m, the height is 3.2m, the gas ascending flow rate is controlled at 1.8cm / s, and the volume of the integrated aerobic granular sludge membrane bioreactor is 1.6 L, the temperature is controlled at 25°C, the pH is 7.5, and the aeration int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com