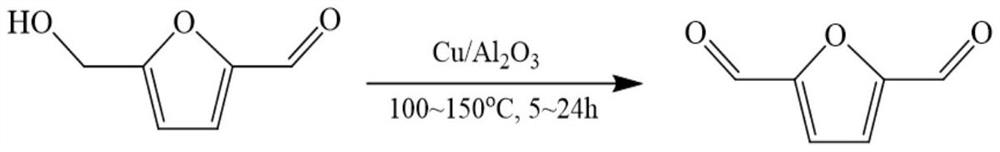

A kind of method for preparing 2,5-furandicarboxaldehyde by dehydrogenation of 5-hydroxymethyl furfural

A technology of hydroxymethylfurfural and furandicarbaldehyde, applied in the field of 5-hydroxymethylfurfural dehydrogenation to prepare 2,5-furandicarbaldehyde, which can solve the problem of flammability and explosion of molecular oxygen, low atom utilization rate and low catalytic efficiency and other problems, to achieve the effect of high atom utilization, good application prospects, and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the catalyst is also the knowledge technology. The following is a specific example (but not limited to this):

[0029] In the first step, the saturated water absorption of the carrier is accurately called each carrier 1.0g on the surface dish, adding the pure water to the carrier to the wet and slightly flowing, the volume of the pure water used in the record is Essence

[0030] In the second step, the immersion legal preparation load metal catalyst: accurately referred to as the carrier 2.0G carrier in the 坩埚. Accurately weigh 0.4g Cu (NO 3 Cure 2 · 3H 2 O in the cup, add the saturated water absorption of the carrier measured in the first step, which is completely dissolved. Add the copper solution to the carrier until the carrier is completely soaked and slightly flowing. After standing for 12h, use the Maval furnace to bake the catalyst and bake it for 4h at 400 ° C. After being baked, immerse the additive NI in the same way.

[0031] The third ...

Embodiment 1

[0033] 5-hydroxymamoltalcal (5mmol), average trilum (15ml), and the reduced 6.6WT % CU / γ-Al restored 2 O 3 Catalyst (1.0g) adds a high -pressure reactor to pass N 2 The air in the reaction kettle is empty and the reaction is stopped after the mechanical stirring reaction is 12h at 150 ° C. The reaction was cooled to room temperature, the upper liquid was separated from the upper layer, the catalyst sank at the bottom, and the upper layer of clear liquid was analyzed directly on the gas chromatography. The income of formaldehyde was 36.6 %.

[0034] Among them, the product detection method: After the reaction is over, the reaction solution is separated by centrifugal solution. After the upper liquid is separated and filtered, the gas chromatography is performed.

Embodiment 2

[0036] Other steps are the same as Example 1, the difference is that the catalyst that is added is 6.6WT % CU / γ-AL. 2 O 3 The reaction result was that the conversion rate of 5-hydroxydamyle was 44.9 %, and the yield of 2,5-fuu two formaldehyde was 35.2 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com