Waterborne hydrophobic oleophobic metal paint and preparation method thereof

A hydrophobic and oleophobic, metallic paint technology, applied in the direction of graft polymer adhesives, adhesive types, film/sheet release liners, etc., can solve the problem of expensive metal powder, unstable metal powder, chemical reaction Improve product stability and quality, improve compatibility, and lower reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

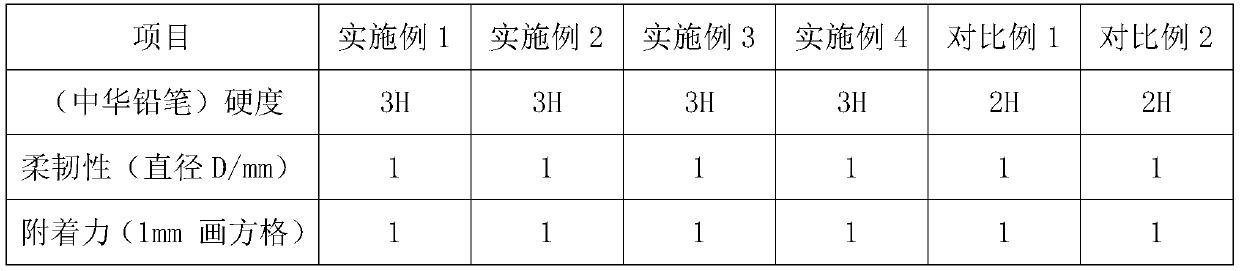

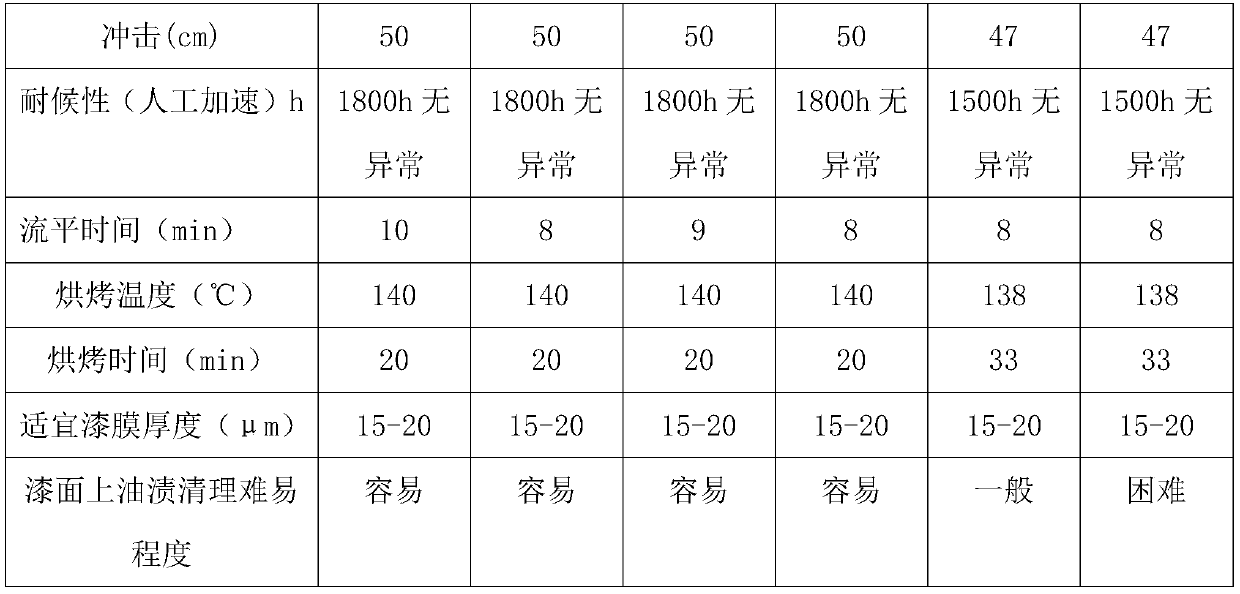

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing the above-mentioned water-based hydrophobic and oleophobic metallic paint, including the configuration process of the base varnish and the adjustment process of the color paint, wherein the preparation process of the base varnish comprises the following steps:

[0045] (1) Add water-based polyester modified acrylic resin, PH regulator, co-solvent, and disperse for 5-10min at a speed of 600-900r / min;

[0046] (2) Add deionized water, defoamer, wetting agent, leveling agent, hydrophobic and oleophobic additives in sequence, and disperse for 10-20min at a speed of 900-1200r / min;

[0047] (3) Add high imino methyl etherified amino resin, disperse for 10-15min at a rotating speed of 1000-1300r / min, and obtain a basic varnish.

[0048]Further, the adjustment process of the color paint comprises the following steps:

[0049] (1) Add basic varnish, and disperse for 10-15min at a speed of 600-800r / min;

[0050] (2) dis...

Embodiment 1

[0054] A water-based hydrophobic and oleophobic metallic paint, in parts by mass, comprises the following components:

[0055] 80 parts of basic varnish, 5 parts of metallic pigment, 4 parts of co-solvent, 15 parts of water-based self-made resin color paste.

[0056] In the above scheme, the basic varnish includes the following components in parts by mass: 35 parts of water-based polyester modified acrylic resin, 2 parts of pH regulator, 0.4 part of defoamer, 15 parts of film-forming aid, wetting 0.4 parts of agent, 0.3 parts of leveling agent, 2 parts of water-based hydrophobic and oleophobic additives, 5 parts of deionized water, and 13 parts of high imino methyl etherified amino resin.

[0057] In the above scheme, the pH regulator is dimethylethanolamine.

[0058] The defoamer is BYK-028.

[0059] The wetting agent is Tego-100.

[0060] The film-forming aid is isopropanol.

[0061] Further, the pH regulator is dimethylethanolamine.

[0062] The preparation method of a...

Embodiment 2

[0071] A water-based hydrophobic and oleophobic metallic paint, in parts by mass, comprises the following components:

[0072] 75 parts of basic varnish, 5 parts of metallic pigment, 3 parts of co-solvent, 18 parts of water-based self-made resin color paste.

[0073] In the above scheme, the base varnish includes the following components in parts by mass: 34 parts of water-based polyester modified acrylic resin, 1.8 parts of pH regulator, 0.4 part of defoamer, 18 parts of film-forming aid, wetting 0.3 parts of agent, 0.4 parts of leveling agent, 2 parts of water-based hydrophobic and oleophobic additives, 23 parts of deionized water, and 13 parts of high imino methyl etherified amino resin.

[0074] In the above scheme, the pH regulator is dimethylethanolamine.

[0075] The defoamer is BYK024.

[0076] The wetting agent is AFCONA-3031.

[0077] The film-forming aid is propylene glycol butyl ether.

[0078] Further, the pH regulator is dimethylethanolamine.

[0079] The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com