Corrosion inhibitor for improving ablation resistance of metal and preparation method of corrosion inhibitor

A corrosion inhibitor and ablation-resistant technology, which is applied in the field of corrosion inhibitors and their preparations for improving metal ablation resistance, can solve the problems of low corrosion inhibition efficiency and inconvenient use of corrosion inhibitors, achieve long dehydration cycle, overcome Effect of incomplete combustion and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

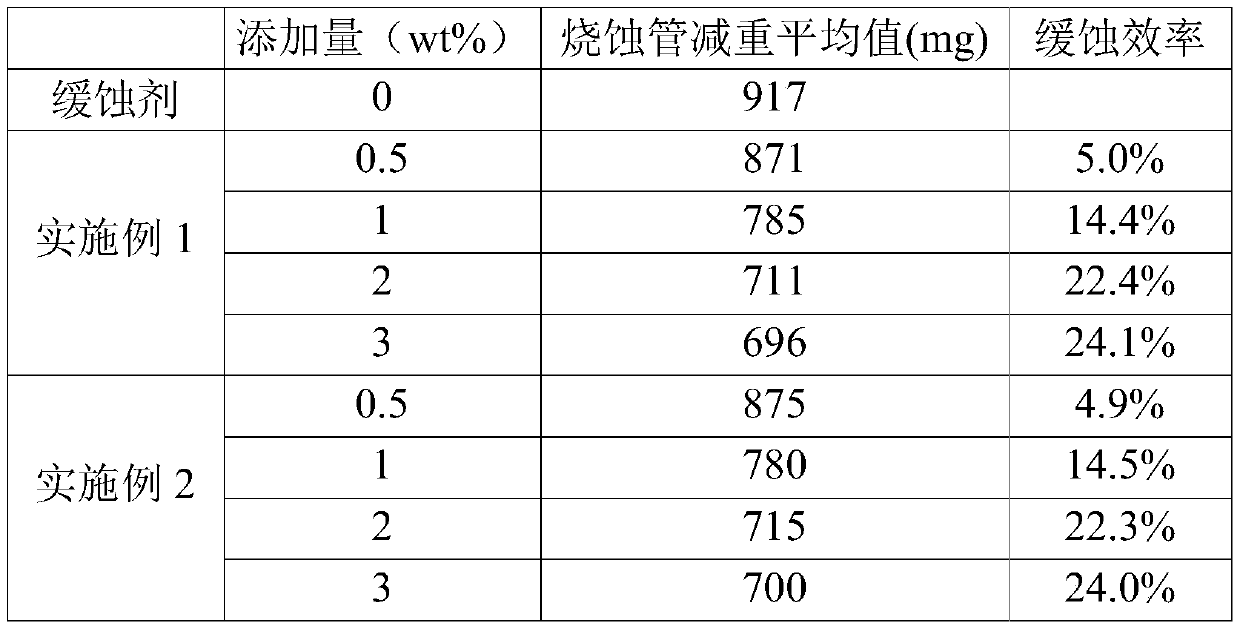

Embodiment 1

[0047]The embodiment of the present invention provides a corrosion inhibitor with core-shell structure, which uses titanium hydroxide as the core material and polyvinyl butyral as the wall material. The particle size of the above-mentioned titanium hydroxide is 0.5 μm, the viscosity of the polyvinyl butyral is 40 mPa·s, and the test conditions of the viscosity are: polyvinyl butyral-10 vol% ethanol solution, and the test temperature is 20° C. The mass ratio of the above-mentioned titanium hydroxide to polyvinyl butyral is 1:0.24.

[0048] The preparation method of above-mentioned corrosion inhibitor comprises the following steps:

[0049] Step a, weighing 2.4 g of the polyvinyl butyral and dissolving it in 117.6 g of ethanol, stirring at a speed of 500 rpm for 1.5 h, and then standing for 12 h to obtain the first solution;

[0050] Step b. Weighing 10 g of titanium hydroxide, 12 g of ethanol and 0.12 g of Span 80 and mixing them, stirring and mixing thoroughly, and then ultra...

Embodiment 2

[0053] The embodiment of the present invention provides a corrosion inhibitor with core-shell structure, which uses titanium hydroxide as the core material and polyvinyl butyral as the wall material. The particle size of the above-mentioned titanium hydroxide is 0.7 μm, the viscosity of the polyvinyl butyral is 50 mPa·s, and the test conditions of the viscosity are: polyvinyl butyral-10 vol% ethanol solution, and the test temperature is 20° C. The mass ratio of the above-mentioned titanium hydroxide to polyvinyl butyral is 1:0.3.

[0054] The preparation method of above-mentioned corrosion inhibitor comprises the following steps:

[0055] Step a, weighing 1.2 g of the polyvinyl butyral and dissolving it in 118.8 g of absolute ethanol, stirring at a speed of 400 rpm for 2 h, and then standing for 10 h to obtain the first solution;

[0056] Step b. Weigh 4 g of titanium hydroxide, 8 g of absolute ethanol and 0.04 g of Span 80 and mix them, stir and mix thoroughly, and then ultr...

Embodiment 3

[0059] The embodiment of the present invention provides a corrosion inhibitor with core-shell structure, which uses titanium hydroxide as the core material and polyvinyl butyral as the wall material. The particle size of the above-mentioned titanium hydroxide is 0.3 μm, the viscosity of the polyvinyl butyral is 25 mPa·s, and the test conditions of the viscosity are: polyvinyl butyral-10 vol% ethanol solution, and the test temperature is 20° C. The mass ratio of the above-mentioned titanium hydroxide to polyvinyl butyral is 1:0.2.

[0060] The preparation method of above-mentioned corrosion inhibitor comprises the following steps:

[0061] Step a, weighing 3.6 g of the polyvinyl butyral and dissolving it in 116.4 g of absolute ethanol, stirring at a speed of 700 rpm for 1.5 h, and then standing for 14 h to obtain the first solution;

[0062] Step b. Weighing 18g of titanium hydroxide, 18g of absolute ethanol and 0.36g of Span 80 and mixing them, stirring and mixing thoroughly,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com