Mass transfer enhancement type CO2 electroreduction electrolysis tank

A technology of CO2 and electrolytic cells, applied in electrolytic process, electrolytic components, electrolytic organic production, etc., can solve problems such as inability to run stably for a long time and affect the stability of product yield, so as to reduce the speed of attenuation and increase the degree of reaction , the effect of increasing the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

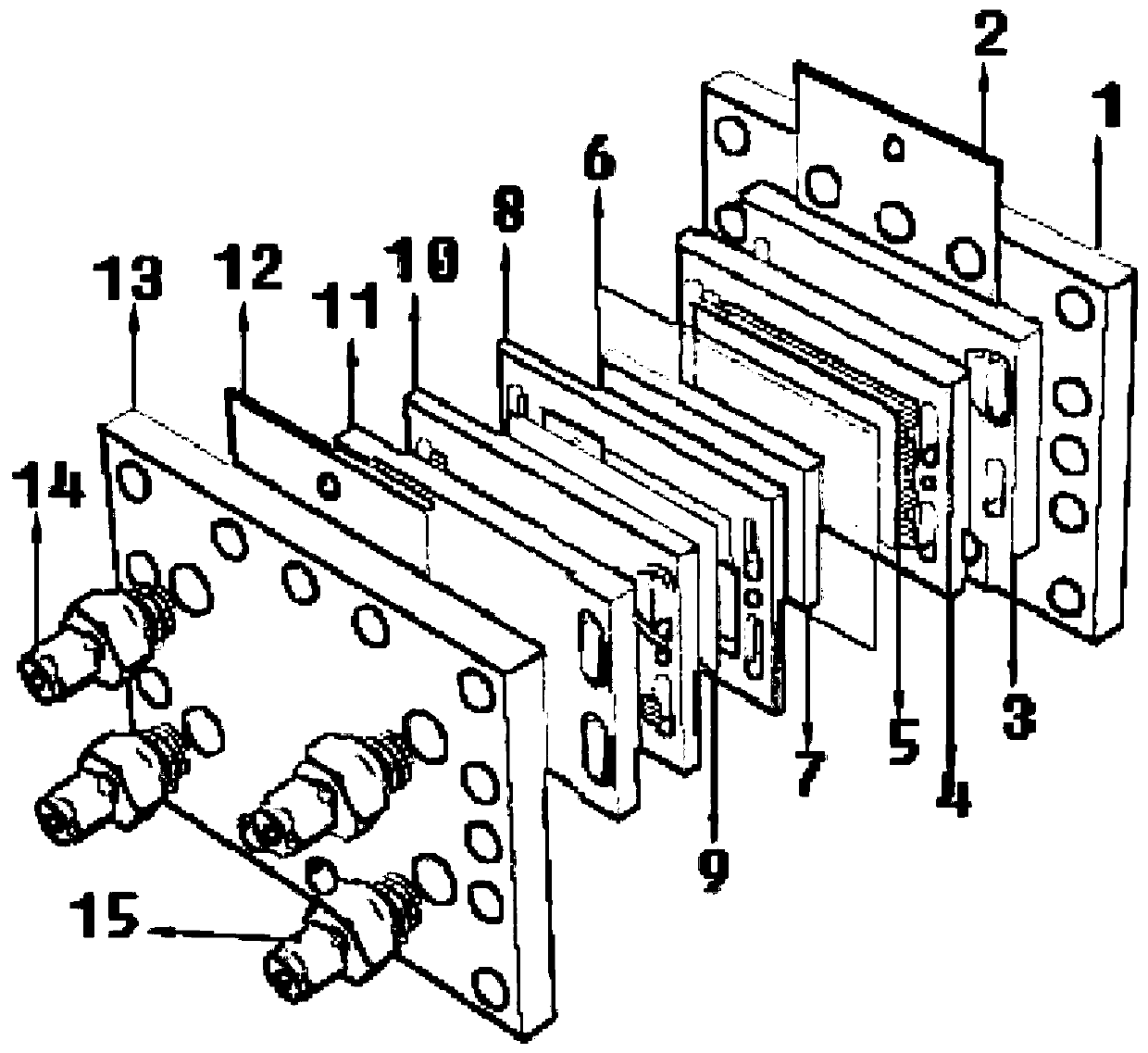

[0058] This embodiment provides an electrolytic cell for electroreducing carbon dioxide, such as figure 1 As shown, it includes a cathode assembly, an anode assembly and a diaphragm 6 that separates the two, and the diaphragm 6 is specifically an ion exchange membrane, more specifically a perfluorosulfonic acid proton exchange membrane (Nafion membrane); the cathode assembly has an electrolyte support layer connected in sequence 7. Solution flow field plate 8, cathode gas diffusion electrode 9, cathode flow field plate 10, cathode fluid distribution plate 11, cathode current collecting plate 12 and cathode end plate 13; The flow plate 2 , the anode fluid distribution plate 3 , the anode flow field plate 4 and the anode electrode plate 5 ; the diaphragm 6 is arranged between the electrolyte support layer 7 and the anode electrode plate 5 .

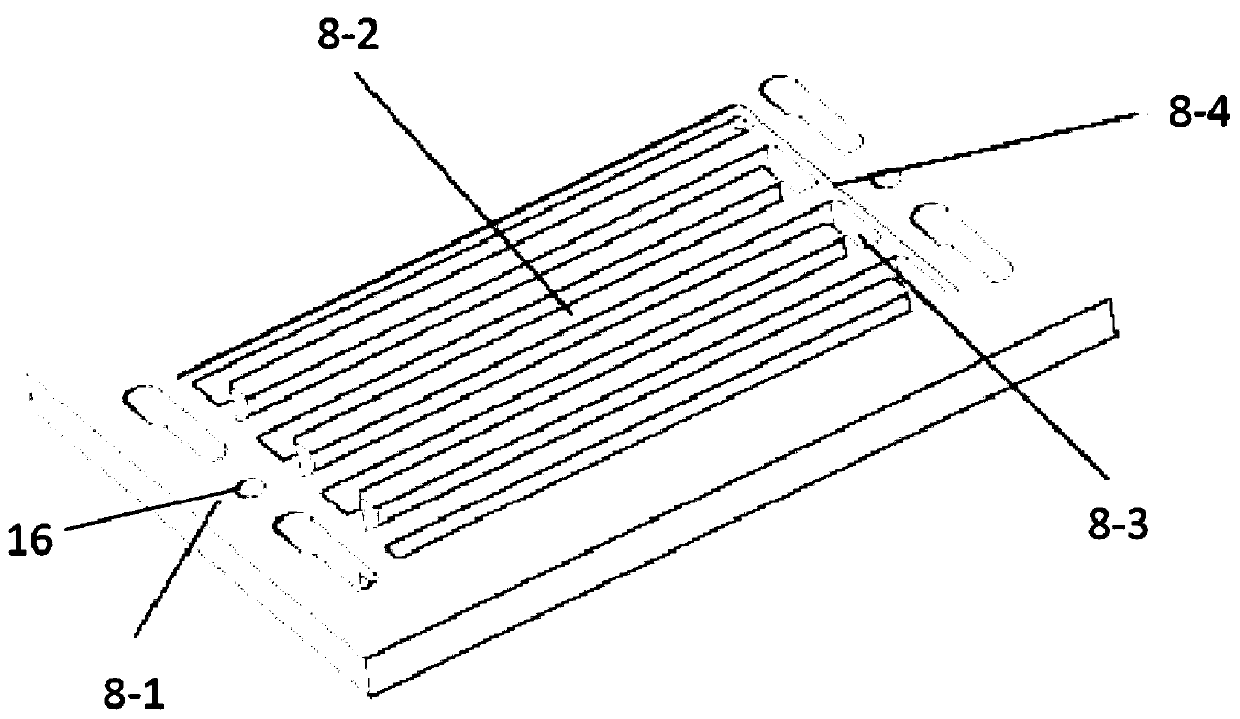

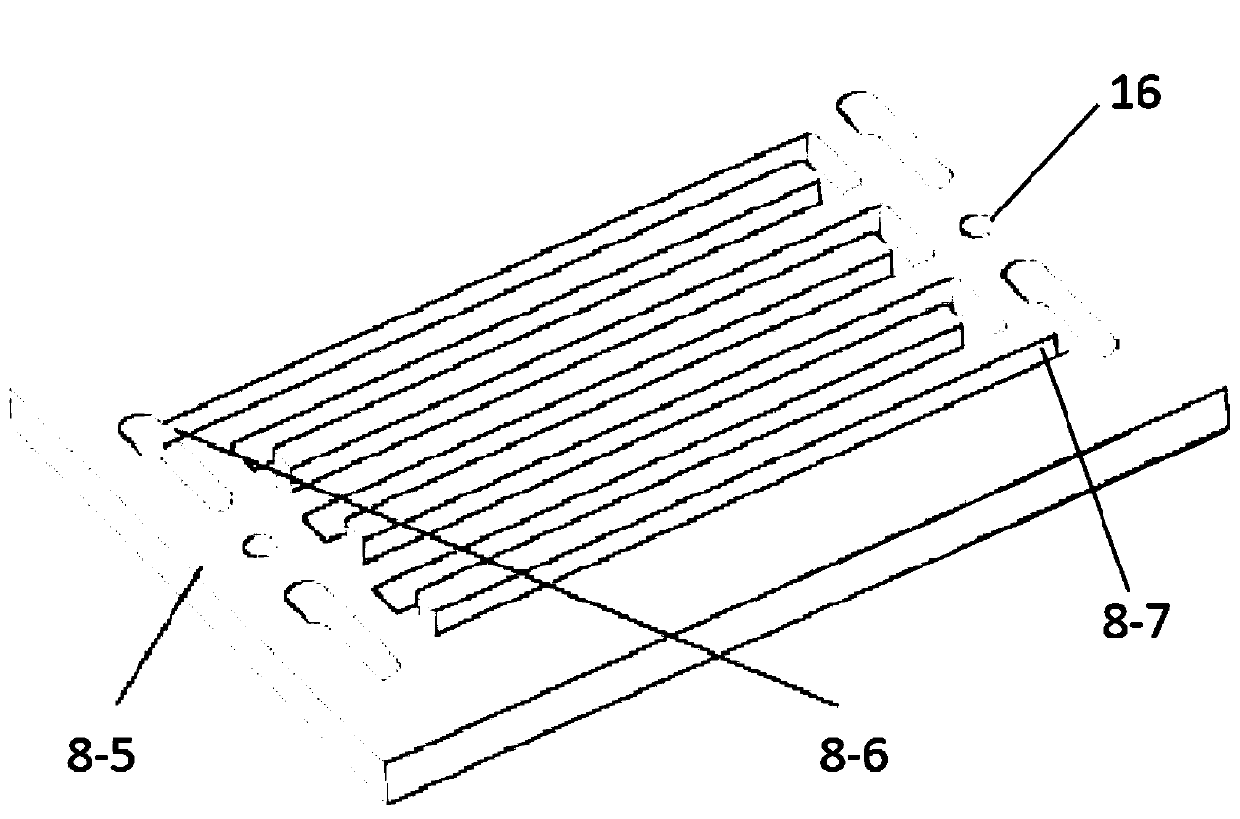

[0059] Such as Figure 2-3 As shown, the solution flow field plate 8 includes a first insulating surface 8-1 and a second insulating surf...

Embodiment 2

[0074] In order to verify the electrolytic cell for electroreduction of carbon dioxide with a unique structure of the present invention, a solution flow field plate with a thickness of 5 mm was selected to explore the influence of electrolyte flow rate on the performance and stability of carbon dioxide electroreduction. Among them, the electrolyte is potassium bicarbonate aqueous solution, the concentration of the electrolyte is 0.5mol / L, the operating temperature of the system is 25°C, and the working voltage is 0V~-10V. The structure of the electrolytic cell used in this embodiment is consistent with that of Embodiment 1. The corresponding test results are as Figure 6-Figure 7 shown.

[0075] from Image 6 It can be seen that when the battery voltage is -6.5V, when the electrolyte flow rate increases from 0ml / min to 4ml / min, the current density also increases from -8.90mA / cm 2 Boost to -33.38mA / cm 2 , indicating that the flow of electrolyte can significantly enhance the...

Embodiment 3

[0078] In order to verify the electrolytic cell for electroreduction of carbon dioxide with the unique structure of the present invention, a solution flow field plate with a thickness of 2 mm was selected to explore the influence of electrolyte flow rate on the performance and stability of carbon dioxide electroreduction. Among them, the electrolyte is potassium bicarbonate aqueous solution, the concentration of the electrolyte is 0.5mol / L, the operating temperature of the system is 25°C, and the working voltage is 0V~-10V. The structure of the electrolytic cell used in this embodiment is consistent with that of Embodiment 1. The corresponding test results are as Figure 8-Figure 9 shown.

[0079] from Figure 8 It can be seen that when the battery voltage is -10V, when the electrolyte flow rate increases from 1ml / min to 4ml / min, the current density also increases from -16.14mA / cm 2 Boost to -59.36mA / cm 2 , indicating that the flow of electrolyte can significantly enhance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com