Device applied to rectangular micro-strip millimeter-wave radar sensor

A millimeter-wave radar and millimeter-wave technology, which is applied in the direction of instruments, radiating element structure, radio wave measurement system, etc., can solve the very strict quality requirements of printed circuit board materials, millimeter-wave signal interference, and millimeter-wave signals are easily interfered seriously And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

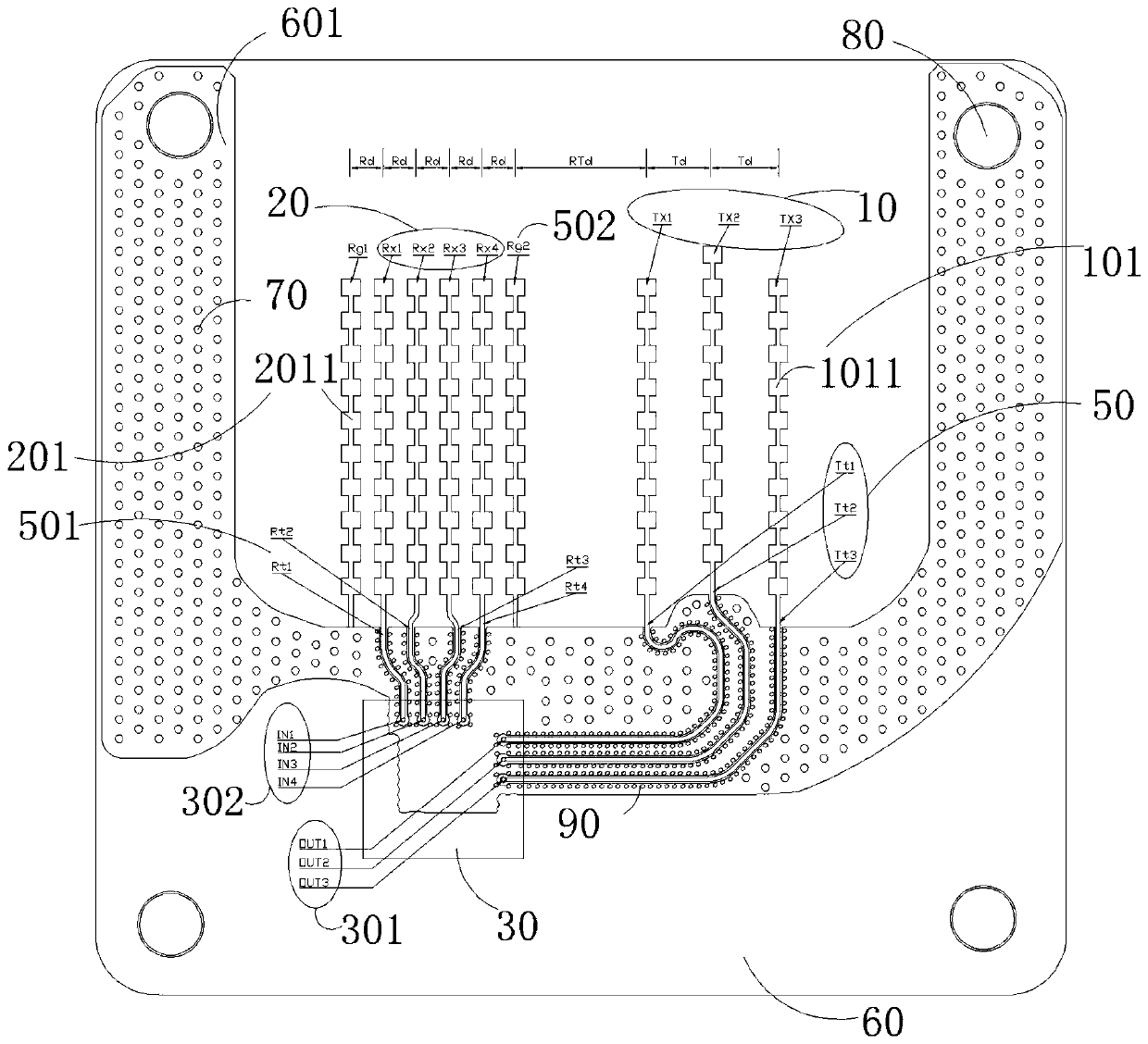

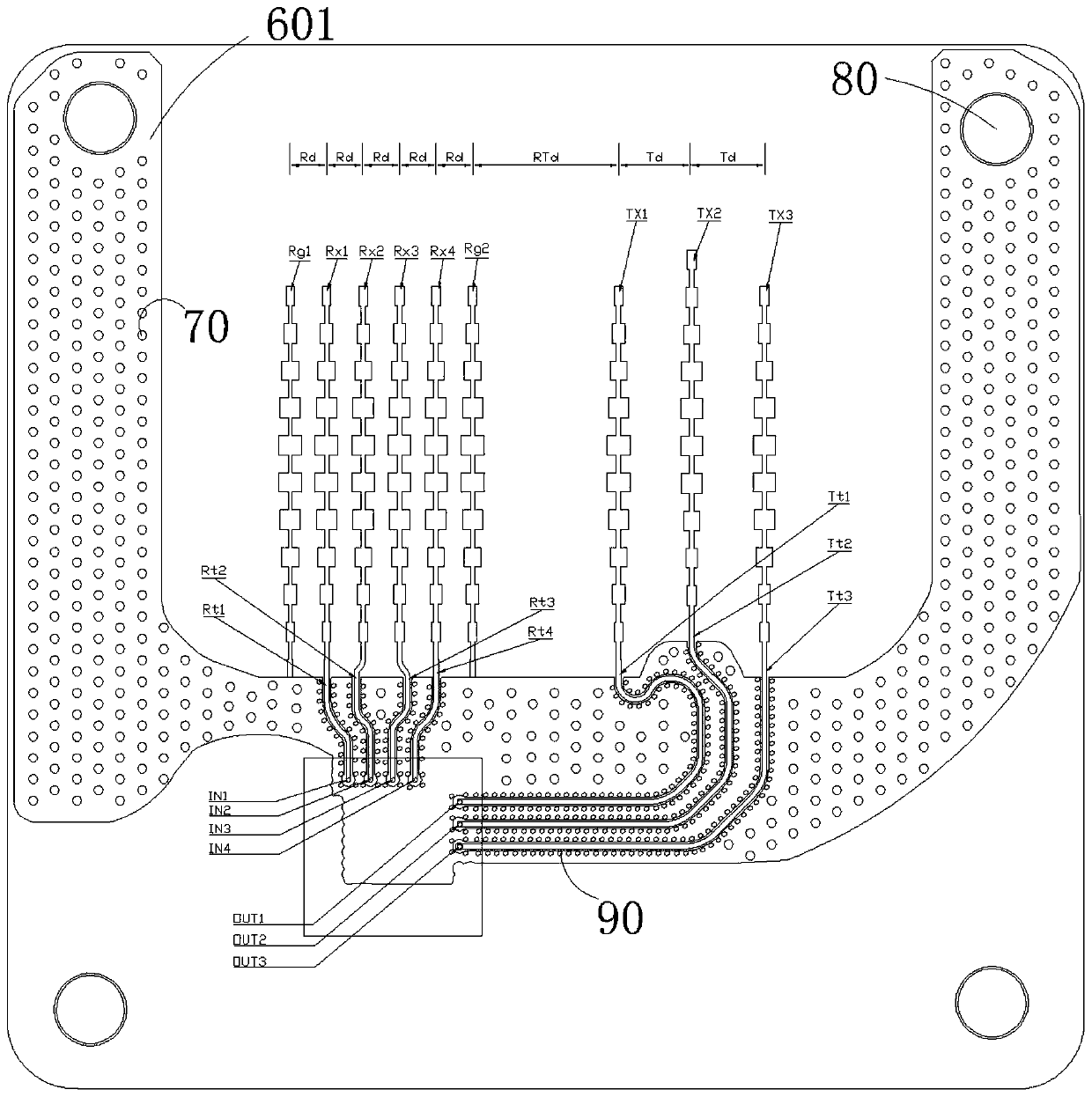

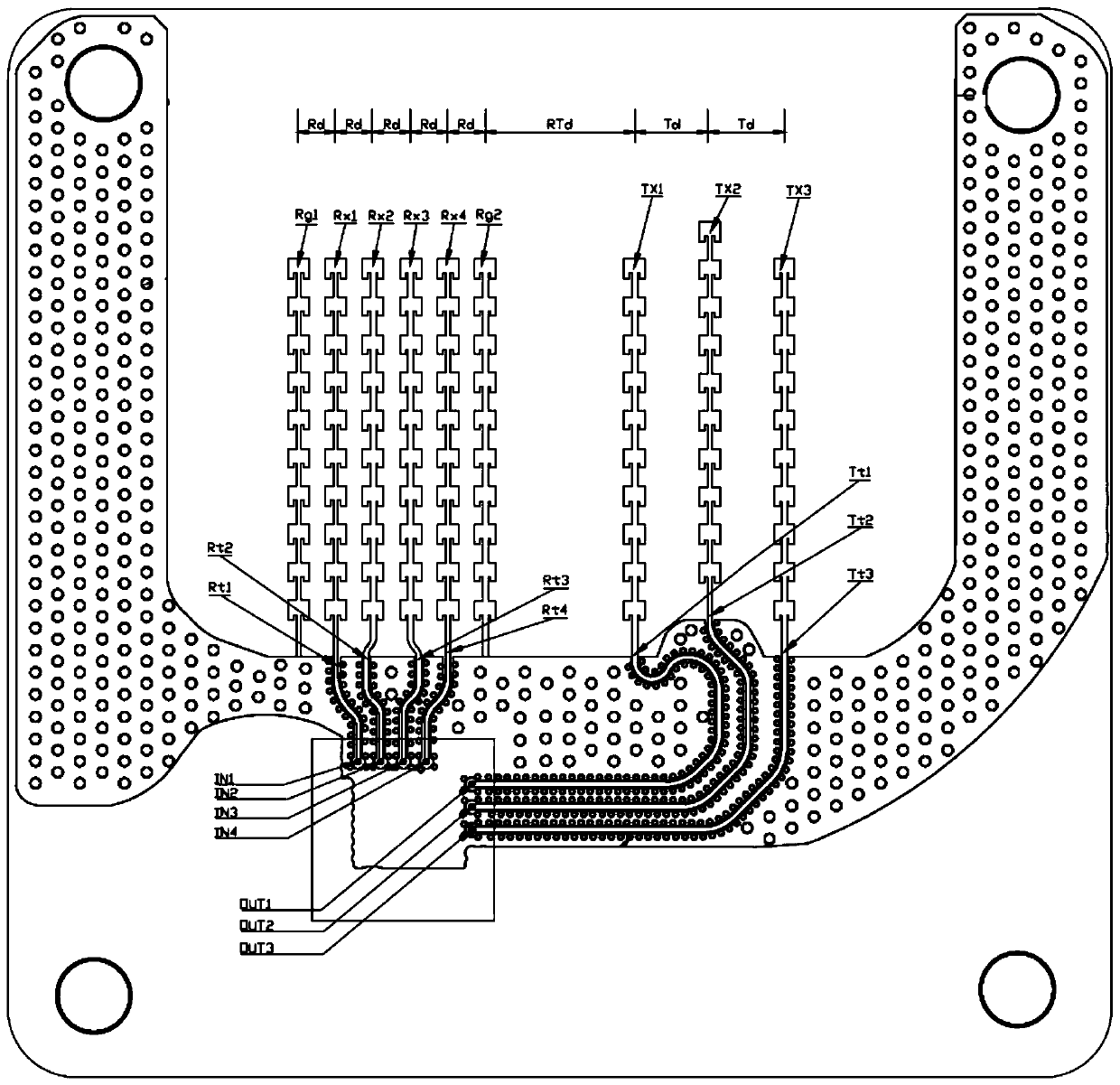

[0101] For the first implementation, see figure 2 The "conical 3D three-transmitter four-receiver single millimeter-wave radar sensor" is the same as the above-mentioned figure 1 The only difference in the "rectangular three-transmission and four-receiver single millimeter-wave radar sensor" is that each series-fed microstrip antenna Tx1, Tx2, Tx3; the width of the rectangular microstrip unit antenna in Rx1, Rx2, Rx3, Rx4 is Taylor ( Taylor) algorithm is modified, so that the side lobe of the transmitted signal on the E plane has a larger attenuation than the main lobe, thereby improving the signal-to-noise ratio of the millimeter-wave radar sensor system and improving the technical effect of the millimeter-wave radar sensor system performance. For the second implementation, see image 3 The "rectangular impedance matching three-dimensional three-transmitter four-receiver single millimeter-wave radar sensor" and figure 1 The only difference in the "rectangular three-transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com