High-frequency high-speed and high-density circuit board manufacturing process

A circuit board manufacturing, high-density technology, applied in the direction of printed circuit manufacturing, printed circuit, printed circuit, etc., can solve the problems of external energy consumption, difficulty, external energy waste, etc., to improve the air circulation speed and improve the stability of use , Increase the effect of cooling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

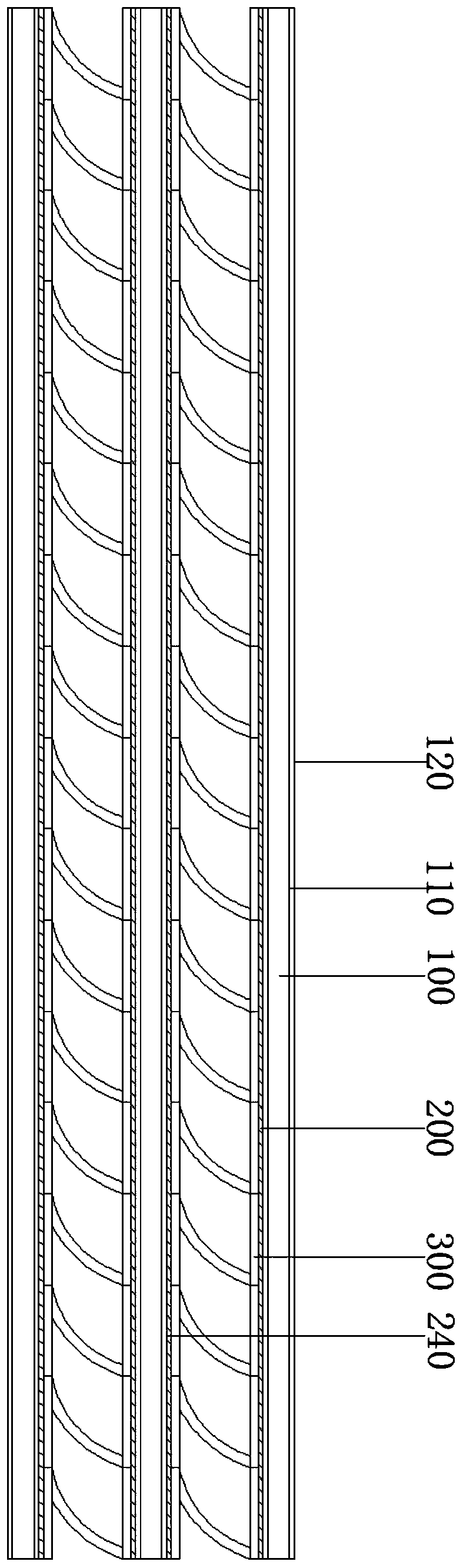

[0043] S1: select the double-sided copper plate 100 to cut into workpieces of different sizes according to the needs of production, and select the predetermined workpiece size according to the size, so as to avoid waste and increase unnecessary costs;

[0044] S2: Copper foil 120 is processed, before being combined with the outer layer, copper foil 120 will be oxidized to form a fine concave-convex surface, and the oxidation treatment time is 35min;

[0045]S3: Paste the photosensitive dry film on the double-sided copper plate 100 as the inner layer, then stick to the film used to make the inner layer wiring, expose, and then perform imaging processing, leaving only the wiring required place, remove unnecessary copper foil 120 by etching;

[0046] S4: the oxidized double-sided copper plate 100 and the outer combined outer layer copper plate 110 are heated in a vacuum state while being compressed by a laminator, and the pressure is normal pressure to form a circuit unit;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com