Crisaborole ointment and preparation method thereof

A technology of criborole and ointment, applied in the field of pharmaceutical preparations, can solve problems such as incomplete elucidation of the mechanism of action, and achieve the effects of solving stability, good uniformity and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 Criborole ointment prescription (100, 60g / ) and preparation process

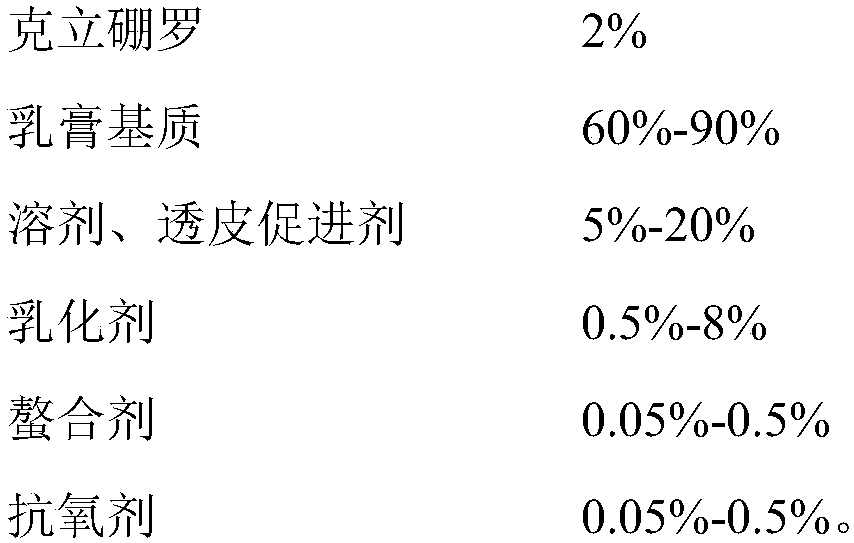

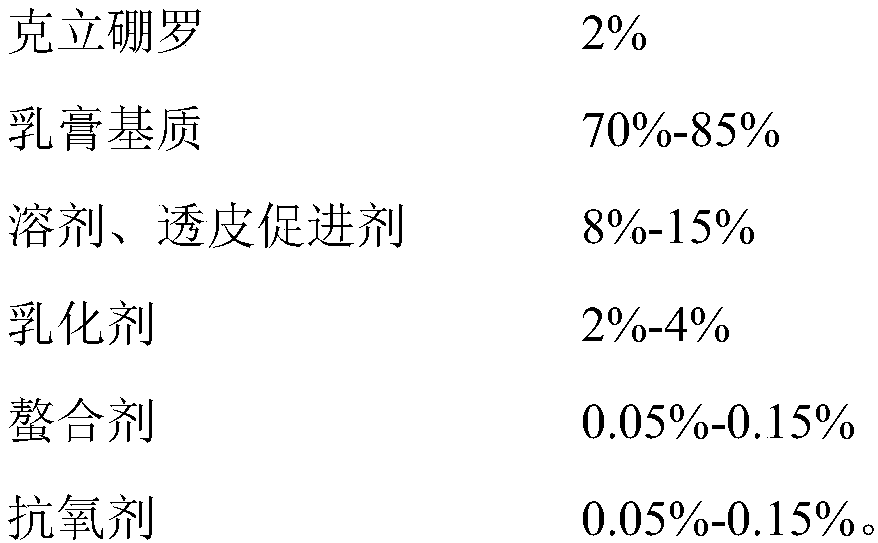

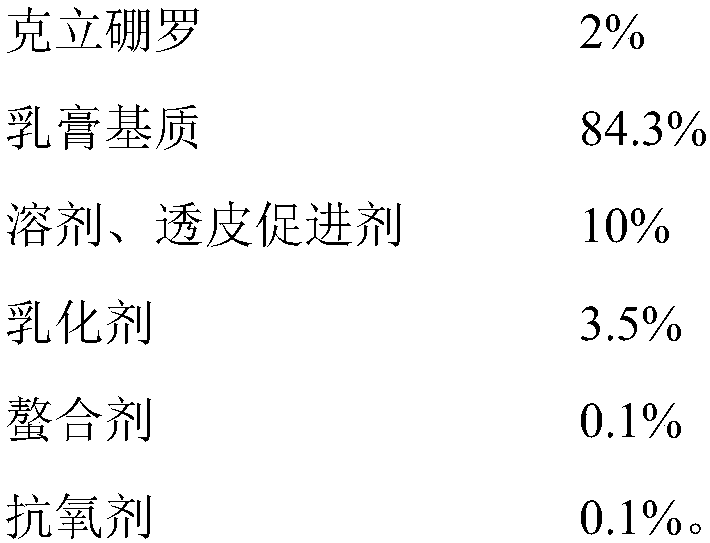

[0043]

[0044] Preparation Process:

[0045] (1) Take 4740g of white petroleum jelly, 318g of liquid paraffin, and 210g of emulsifier glyceryl monostearate and put them into a 10L stainless steel vacuum emulsification tank, turn on the jacket to heat and start stirring, and heat the substrate temperature to 65°C Insulation, as the oil phase;

[0046] (2) Take 600g of the prescribed amount of propylene glycol and place it in a 2L beaker, heat it in a water bath to 45°C and keep it warm, add 6g of the prescribed amount of 2,6-di-tert-butyl-p-cresol and 6g of calcium disodium edetate, and stir until it is completely dissolved, then add 120g of the prescribed amount of crisborole, and stir until the raw materials are completely dissolved;

[0047] (3) Turn on the chilled water jacket to lower the temperature of the material in the oil phase to 45°C and keep it warm. When the temperature o...

Embodiment 2

[0063] Embodiment 2 grams of Riborole ointment prescription (100, 60g / ) and preparation process

[0064]

[0065] Preparation Process:

[0066] (1) Take 4870g of white vaseline, 318g of liquid paraffin, and 230g of emulsifier glyceryl monostearate, and add them into a 10L stainless steel vacuum emulsification tank, turn on the jacket to heat and start stirring, and heat the substrate temperature to 65°C Insulation, as the oil phase;

[0067] (2) Take 450g of the prescribed amount of dimethyl sulfoxide and place it in a 2L beaker, heat it in a water bath to 45°C and keep it warm, add the prescribed amount of 2,6-di-tert-butyl-p-cresol 6g, disodium edetate 6g, stir until completely dissolved, then add 120g of the prescribed amount of crisborole, stir until the raw materials are completely dissolved;

[0068] (3) Turn on the chilled water jacket to lower the temperature of the material in the oil phase to 45°C and keep it warm. When the temperature of (1) drops to about 45°C...

Embodiment 3

[0084] Embodiment 3 grams of Riborole ointment prescription (100, 60g / ) and preparation process

[0085]

[0086] Preparation Process:

[0087] (1) Take 4930g of white vaseline, 318g of liquid paraffin, and 170g of polyoxyethylene fatty acid ester in the prescribed amount, add them to a 10L stainless steel vacuum emulsification tank, turn on the jacket to heat and start stirring, and heat the substrate temperature to 65°C to keep it warm. oil phase;

[0088] (2) Take 600g of the prescribed amount of propylene glycol and place it in a 2L beaker, heat it in a water bath to 45°C and keep it warm, add 6g of the prescribed amount of 2,6-di-tert-butyl-p-cresol and 6g of calcium disodium edetate, and stir until it is completely dissolved, then add 120g of the prescribed amount of crisborole, and stir until the raw materials are completely dissolved;

[0089] (3) Turn on the chilled water jacket to cool the material in the oil phase to 45°C and keep it warm. When the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com