Barium strontium niobate/boron nitride three-dimensional network material and preparation method thereof

A technology of barium strontium niobate and three-dimensional network is applied in the field of barium strontium niobate/boron nitride three-dimensional network material and preparation, which can solve the problems of poor processability and reduced breakdown field strength of composite dielectric films, and achieves Improve dielectric properties, facilitate heat dispersion and transfer, and enhance the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of barium titanate / boron nitride composite material with one-dimensional core-shell structure:

[0022] (1) Slurry configuration: use strontium barium niobate nanopowder, boron nitride nanopowder, polyvinyl alcohol, carboxymethyl cellulose, polyacrylamide, etc. as raw materials, among which strontium barium niobate nanopowder The mass ratio of boron nitride, polyvinyl alcohol, carboxymethyl cellulose and polyacrylamide is 1:0.2:1:1:2 to prepare a good thixotropic slurry;

[0023] (2) Regulation of the pore size of the dry loofah template: prepare 11mol / L NaOH solution, then put the dry loofah in NaOH solution for 20 minutes, wash 3 times, and then dry at 50°C for 2 hours;

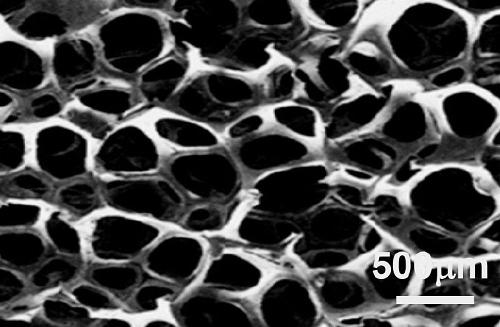

[0024] (3) Preparation of barium strontium niobate / boron nitride three-dimensional network material: soak the treated dry loofah in the above slurry, then extrude to remove excess slurry, and dry at 50°C for 20 hours. Repeat the above slurrying and drying steps twice, heat treat...

Embodiment 2

[0027] A preparation method of barium titanate / boron nitride composite material with one-dimensional core-shell structure:

[0028] (1) Slurry configuration: use strontium barium niobate nanopowder, boron nitride nanopowder, polyvinyl alcohol, carboxymethyl cellulose, polyacrylamide, etc. as raw materials, among which strontium barium niobate nanopowder The mass ratio of boron nitride, polyvinyl alcohol, carboxymethyl cellulose and polyacrylamide is 1:1:2:3:3 to prepare a slurry with good thixotropic properties;

[0029] (2) Regulation of the pore size of the dry loofah template: prepare 8mol / L NaOH solution, then put the dry loofah in NaOH solution for 100min, wash 5 times, and then dry at 120°C for 2h;

[0030] (3) Preparation of barium strontium niobate / boron nitride three-dimensional network material: soak the treated dry loofah in the above slurry, then extrude to remove excess slurry, and dry at 120°C for 2 hours. Repeat the above slurrying and drying steps 10 times, he...

Embodiment 3

[0032] A preparation method of barium titanate / boron nitride composite material with one-dimensional core-shell structure:

[0033] (1) Slurry configuration: use strontium barium niobate nanopowder, boron nitride nanopowder, polyvinyl alcohol, carboxymethyl cellulose, polyacrylamide, etc. as raw materials, among which strontium barium niobate nanopowder The mass ratio of boron nitride, polyvinyl alcohol, carboxymethyl cellulose and polyacrylamide is 1:0.5:1.5:1.5:2.5 to prepare a slurry with good thixotropic properties;

[0034] (2) Regulation of the pore size of the dried loofah template: prepare 5mol / L NaOH solution, then place the dried loofah in NaOH solution for 50min, wash 5 times, and then dry at 100°C for 4.5h;

[0035] (3) Preparation of barium strontium niobate / boron nitride three-dimensional network material: soak the treated dry loofah in the above slurry, then extrude to remove excess slurry, and dry at 100°C for 5 hours. Repeat the above steps of slurrying and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com