LED light-curing flexible photosensitive resin for 3D printing, and preparation method thereof

A 3D printing, photosensitive resin technology, applied in the direction of additive processing, can solve the problems of low temperature resistance, flexibility and poor bending, achieve good flexibility and bending resistance, improve low temperature resistance, reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

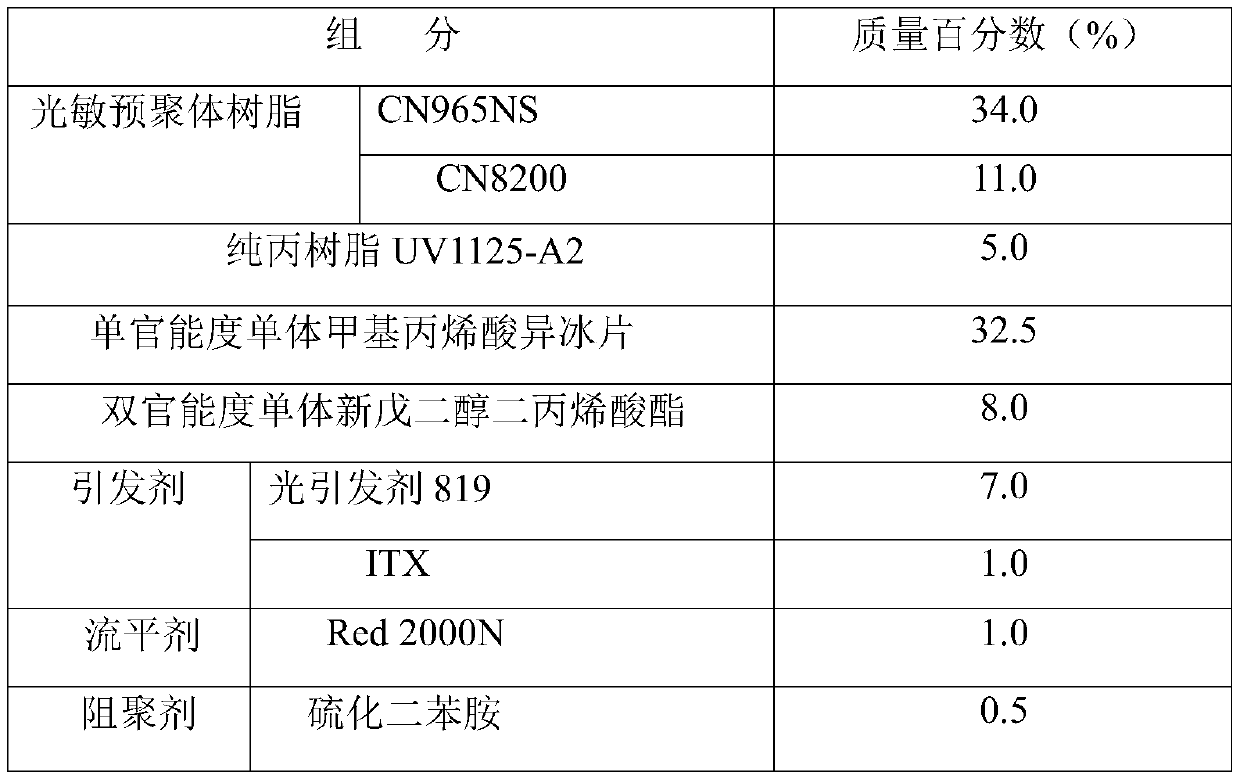

[0047] Table 1 shows the formulation of the LED photocurable low temperature resistant flexible photosensitive resin for 3D printing in this embodiment.

[0048] Table 1

[0049]

[0050] According to the formulations of the components listed in Table 1, at first pure acrylic resin UV1125-A2, photosensitive prepolymer resin CN965NS, CN8200 are added to reactive diluent (monofunctional monomer methacrylic acid isobornyl and difunctional In the monomer neopentyl glycol diacrylate), the resin is completely dissolved when stirring at a high speed of 4500rad / min for 50min, and then adding initiator, leveling agent and polymerization inhibitor under the condition of avoiding light Stirring at a speed of 60 minutes, the LED photocurable flexible photosensitive resin for 3D printing is obtained. The photosensitive resin has a viscosity of 50.52cp at 25°C, and it has good printing fluency on a Polyjet 3D printer. It can be completely cured after being irradiated with LED light with...

Embodiment 2

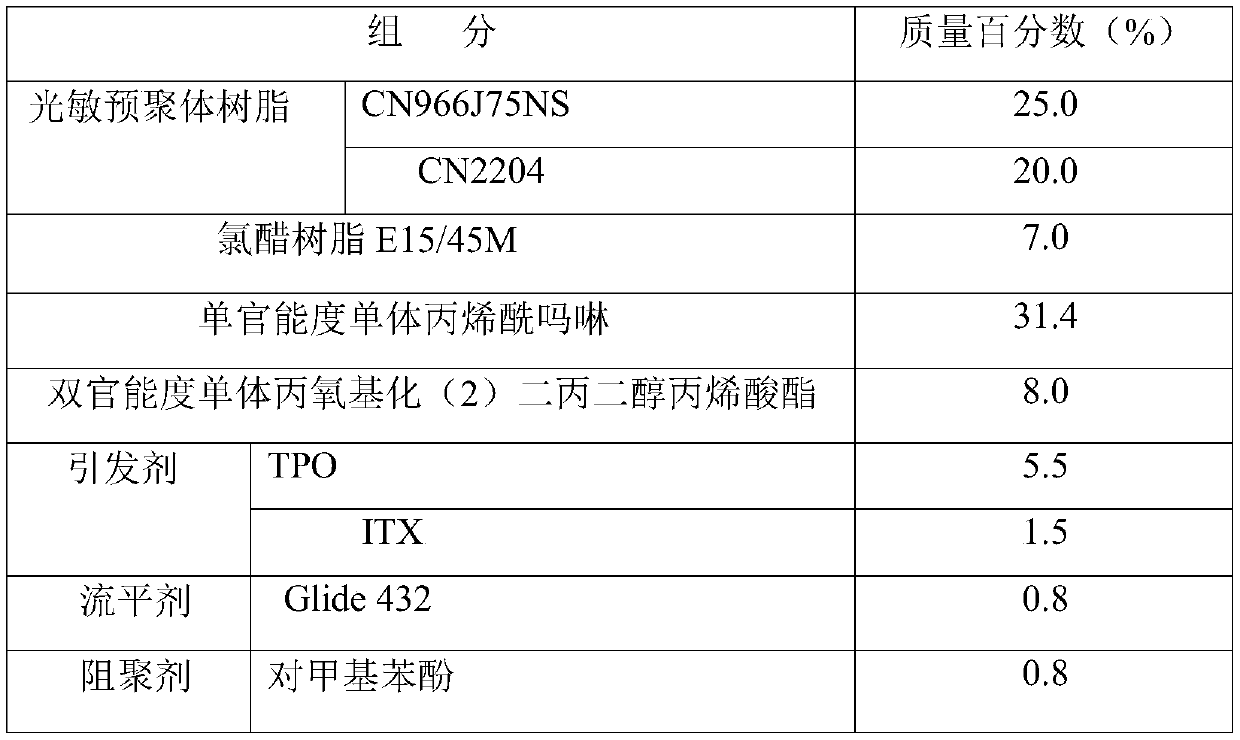

[0052] Table 2 shows the formulation of the LED photocurable low temperature resistant flexible photosensitive resin for 3D printing in this embodiment.

[0053] Table 2

[0054]

[0055] According to the formulations of the components listed in Table 2, firstly, vinyl chloride resin E15 / 45M, photosensitive prepolymer resin CN966J75NS, CN2204 are added to the active diluent (monofunctionality monomer acryloylmorpholine and difunctionality single Propoxylation (2) dipropylene glycol acrylate), when stirring at a high speed of 4000rad / min for 60min, the resin is completely dissolved, and then adding initiator, leveling agent and polymerization inhibitor under the condition of avoiding light and then adding 3500rad / min Stirring at a speed of 50min / min for 3D printing LED photocurable flexible photosensitive resin. The photosensitive resin has a viscosity of 54.29cp at 25°C, and it has good printing fluency on a Polyjet 3D printer. It can be completely cured when irradiated wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com