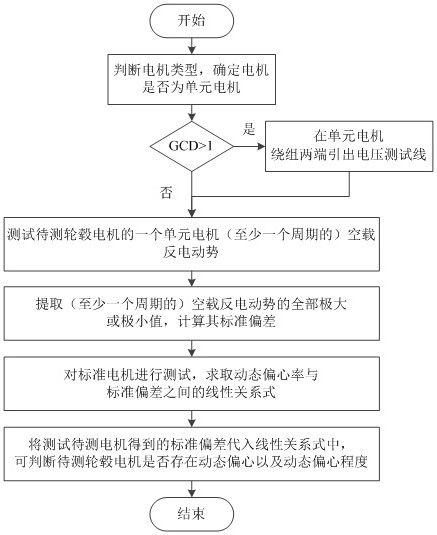

A kind of dynamic eccentricity fault detection method of in-wheel motor

A wheel hub motor and fault detection technology, which is applied in the direction of motor generator testing, measuring devices, and electrical devices, can solve the problems of insufficient testing accuracy, complicated modification process, and complicated testing process, and achieve simple structure, high detection accuracy, and Simple calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

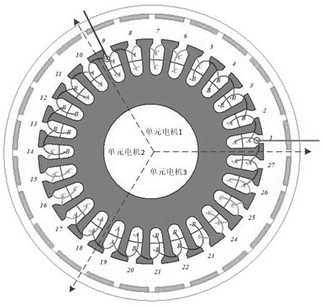

[0045] For a 24-pole 27-slot, rated speed n =600rpm outer rotor wheel hub permanent magnet synchronous motor for electric vehicles, the whole process detection is carried out according to the inventive method.

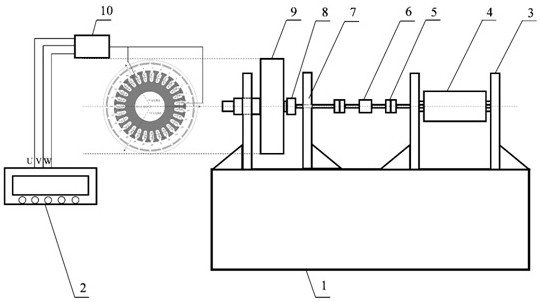

[0046] like figure 1As shown, it is a schematic diagram of the test bench for the no-load back EMF of the in-wheel motor, which is equipped with a test platform 1, a dynamometer 4 for dragging the tested in-wheel motor, and data acquisition and analysis for measuring the no-load back EMF of the in-wheel motor unit motor Module 2. The test platform 1 is provided with a fixture 3 for supporting and clamping the dynamometer 4, a coupling 5 connected with the output shaft of the dynamometer, and a torque speed sensor 6 connected with the coupling 5, and then connected to the The in-wheel motor 9 to be tested is clamped by special in-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com