Method for preparing two-dimensional ultrathin silicon wafer loaded silver nanoparticles

A silver nanoparticle, ultra-thin technology, applied in the field of material chemistry, can solve the problems of application performance impact, complicated synthesis method steps, etc., and achieve the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

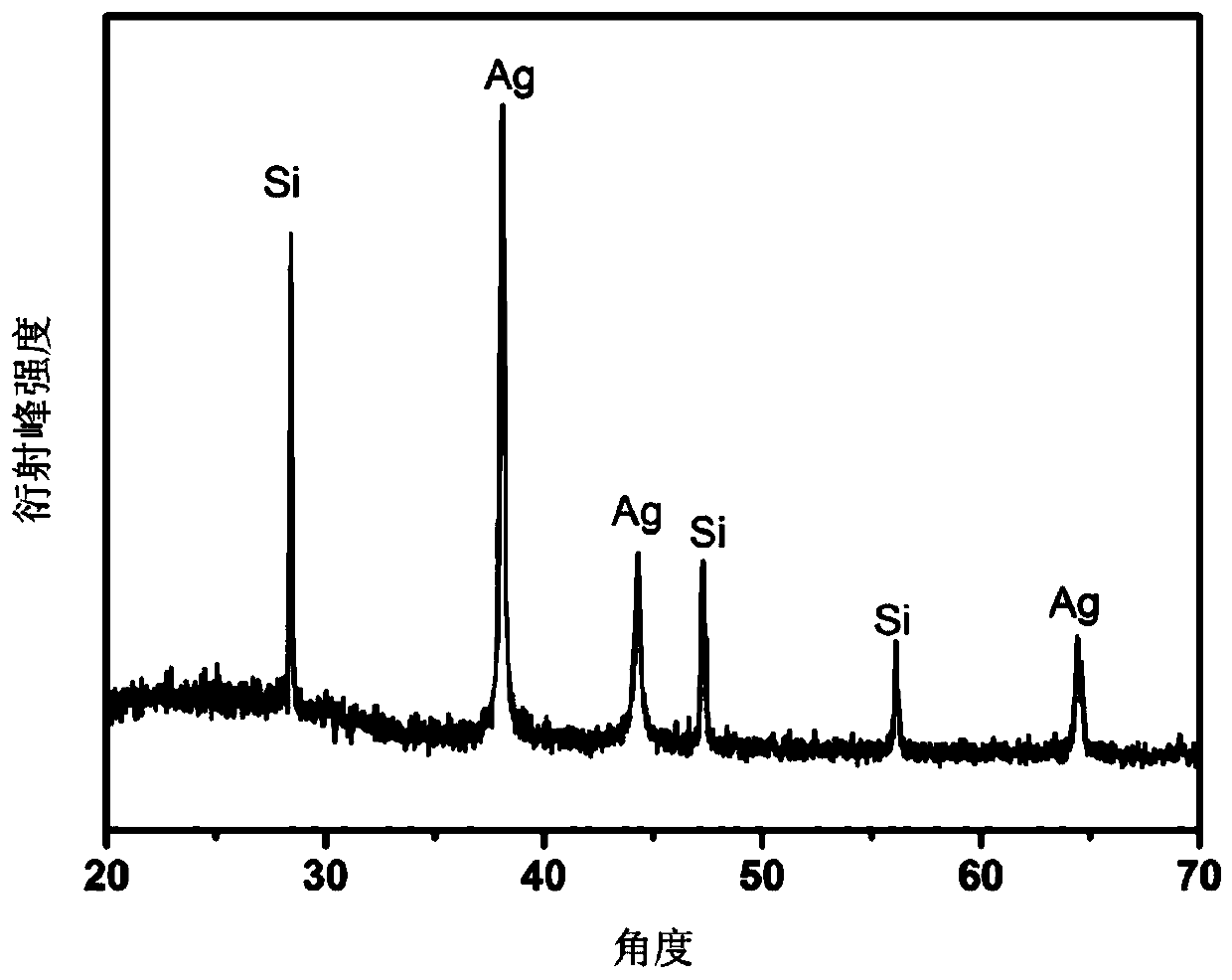

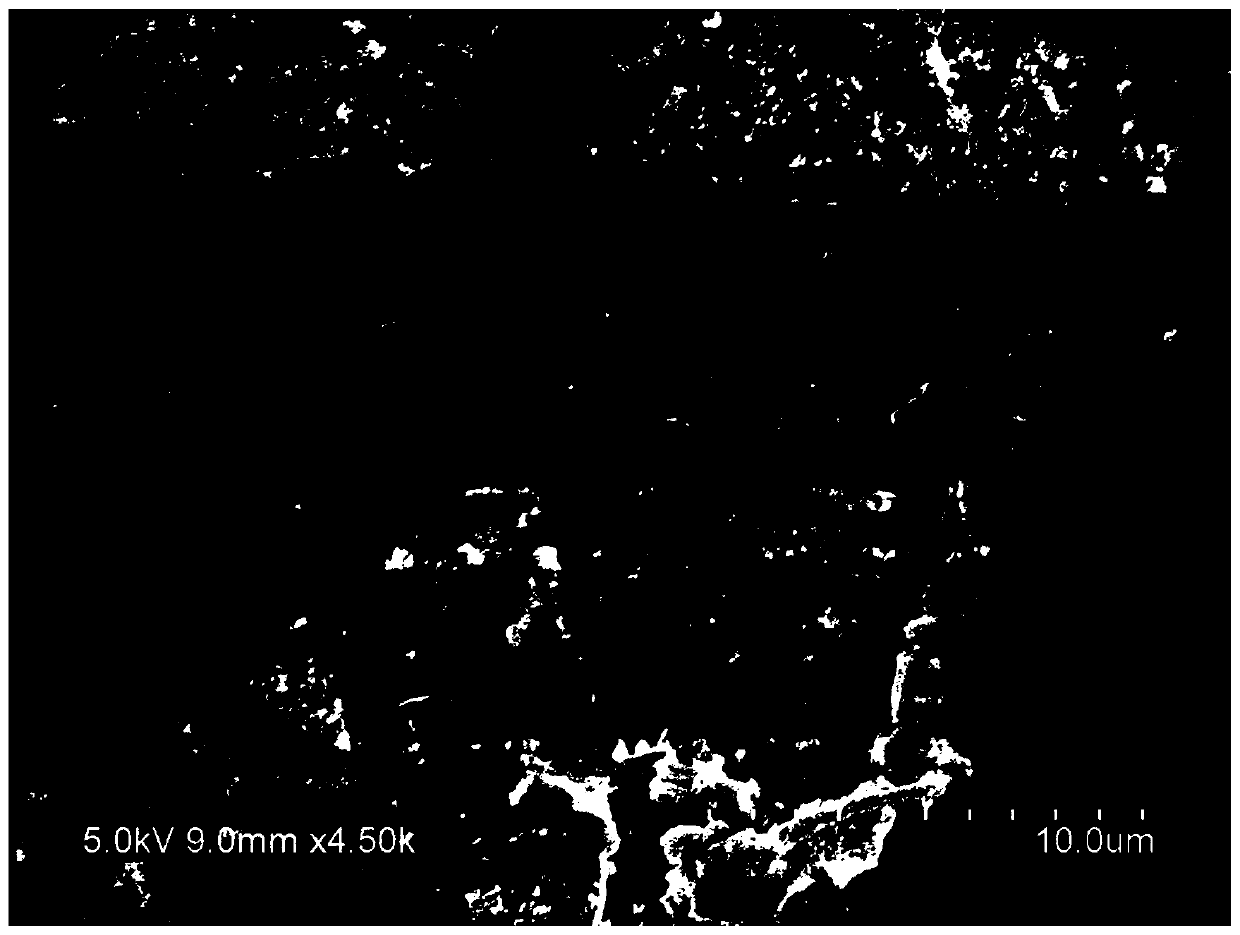

[0028] A method for preparing two-dimensional ultrathin silicon wafers loaded with silver nanoparticles, comprising the following steps:

[0029] (1) Put 3g of calcium silicide in 300mL concentrated hydrochloric acid, react at -30°C for 5 days, filter, wash, and vacuum dry to obtain Si 6 h 6 Nanosheets.

[0030] (2) Dissolve silver nitrate in 10 mL of ethylenediamine to prepare a 0.1M silver nitrate solution in ethylenediamine.

[0031] (3) Add 0.1g Si 6 h 6 The nanosheets were ultrasonically dispersed in 10 mL of acetonitrile, 2 mL of silver nitrate ethylenediamine solution was added, reacted at 60 °C for 24 h at normal pressure, filtered and washed to obtain a composite material with silver nanoparticles loaded on the surface of two-dimensional ultra-thin silicon wafers.

Embodiment 2

[0033] A method for preparing two-dimensional ultrathin silicon wafers loaded with silver nanoparticles, comprising the following steps:

[0034] (1) Put 3g of calcium silicide in 300mL concentrated hydrochloric acid, react at -30°C for 5 days, filter, wash, and vacuum dry to obtain Si 6 h 6 Nanosheets.

[0035] (2) Dissolve silver nitrate in 10 mL of p-phenylenediamine to prepare a silver nitrate p-phenylenediamine solution with a concentration of 0.1M.

[0036] (3) Add 0.1g Si 6 h 6 Ultrasonically disperse the nanosheets in 10mL tetrahydrofuran, add 2mL silver nitrate p-phenylenediamine solution, react at room temperature to 60°C under normal pressure for 1-24h, filter and wash to obtain two-dimensional ultra-thin silicon wafers loaded with silver nanoparticles Granular composites.

Embodiment 3

[0038] A method for preparing two-dimensional ultrathin silicon wafers loaded with silver nanoparticles, comprising the following steps:

[0039] (1) Put 3g of calcium silicide in 300mL concentrated hydrochloric acid, react at -30°C for 5 days, filter, wash, and vacuum dry to obtain Si 6 h 6 Nanosheets.

[0040] (2) Dissolve silver nitrate in 10 mL of tri-n-propylamine to prepare a solution of silver nitrate in tri-n-propylamine with a concentration of 0.1M.

[0041] (3) Add 0.1~1g Si 6 h 6 Ultrasonically disperse nanosheets in 10mL tetrahydrofuran, add 1-10mL silver nitrate tri-n-propylamine solution, react at room temperature to 60°C under normal pressure for 1-24h, filter and wash to obtain two-dimensional ultra-thin silicon wafer surface loaded with silver Composite materials of nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com