Patents

Literature

49 results about "Calcium silicide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium monosilicide (CaSi) is an inorganic compound, a silicide of calcium.

Lead-free primers

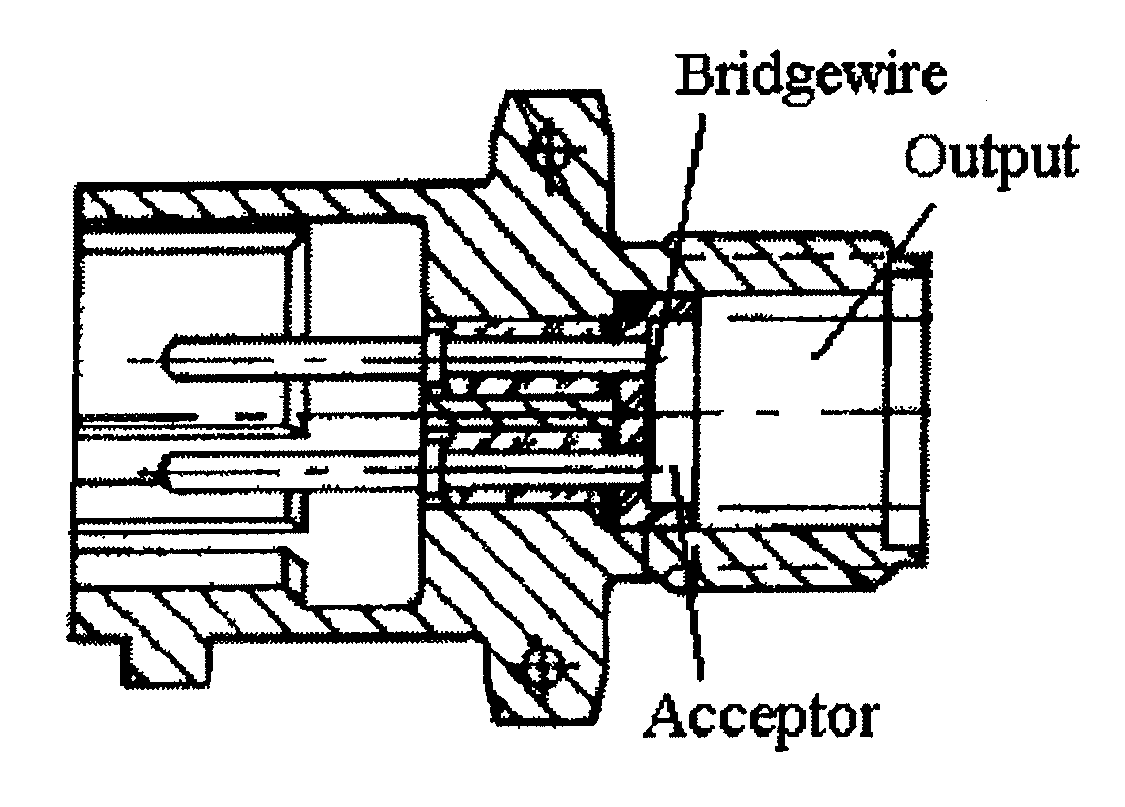

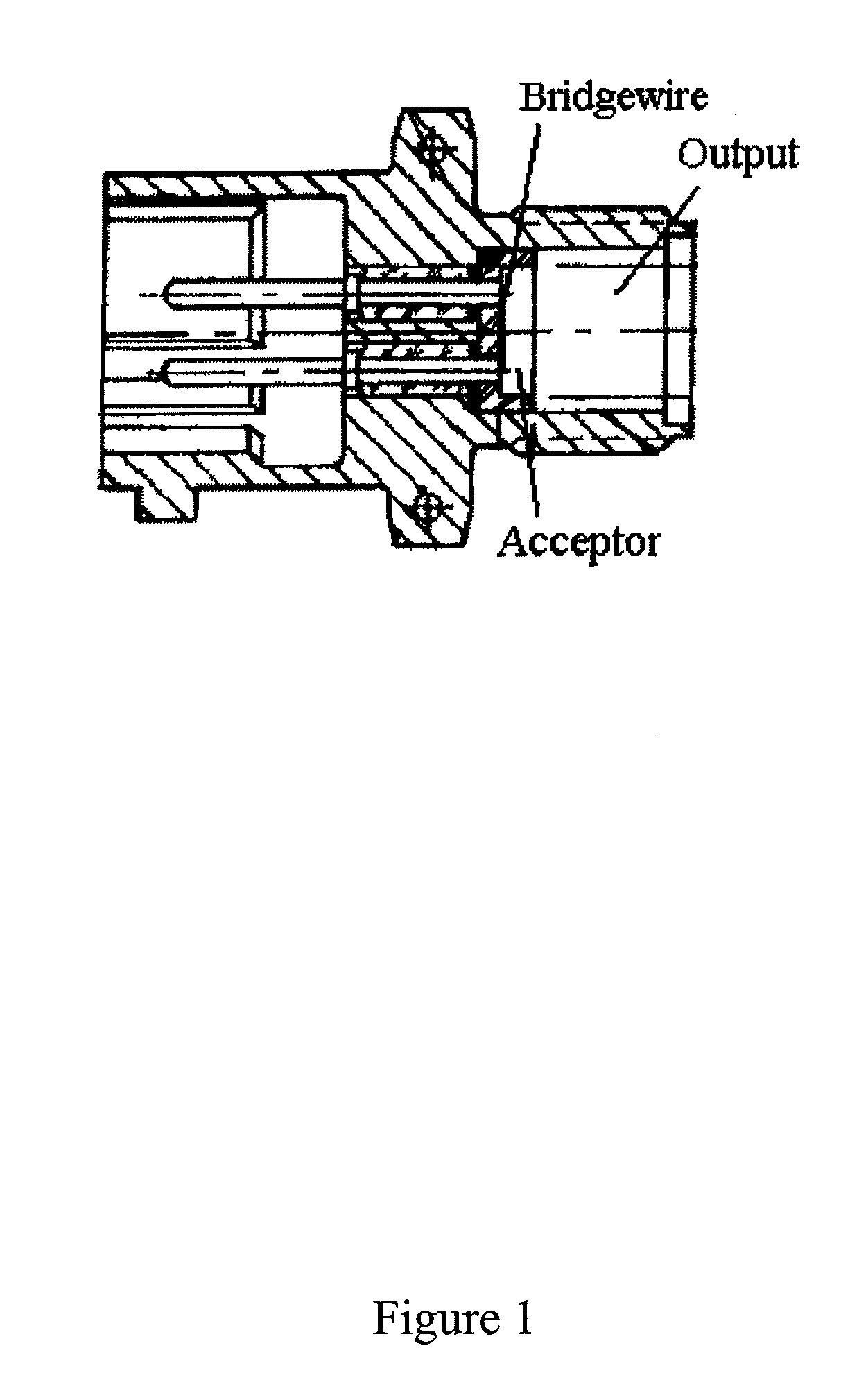

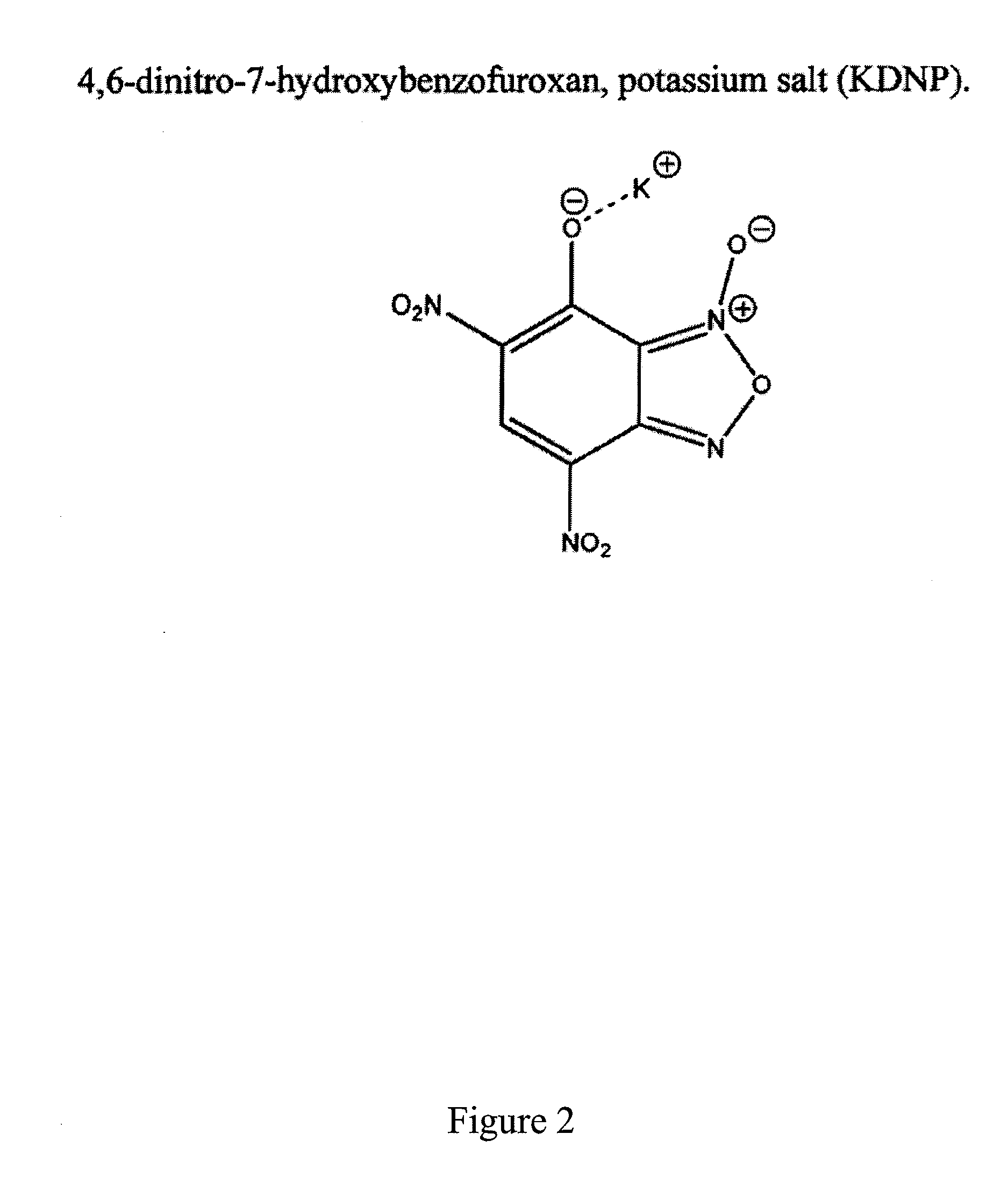

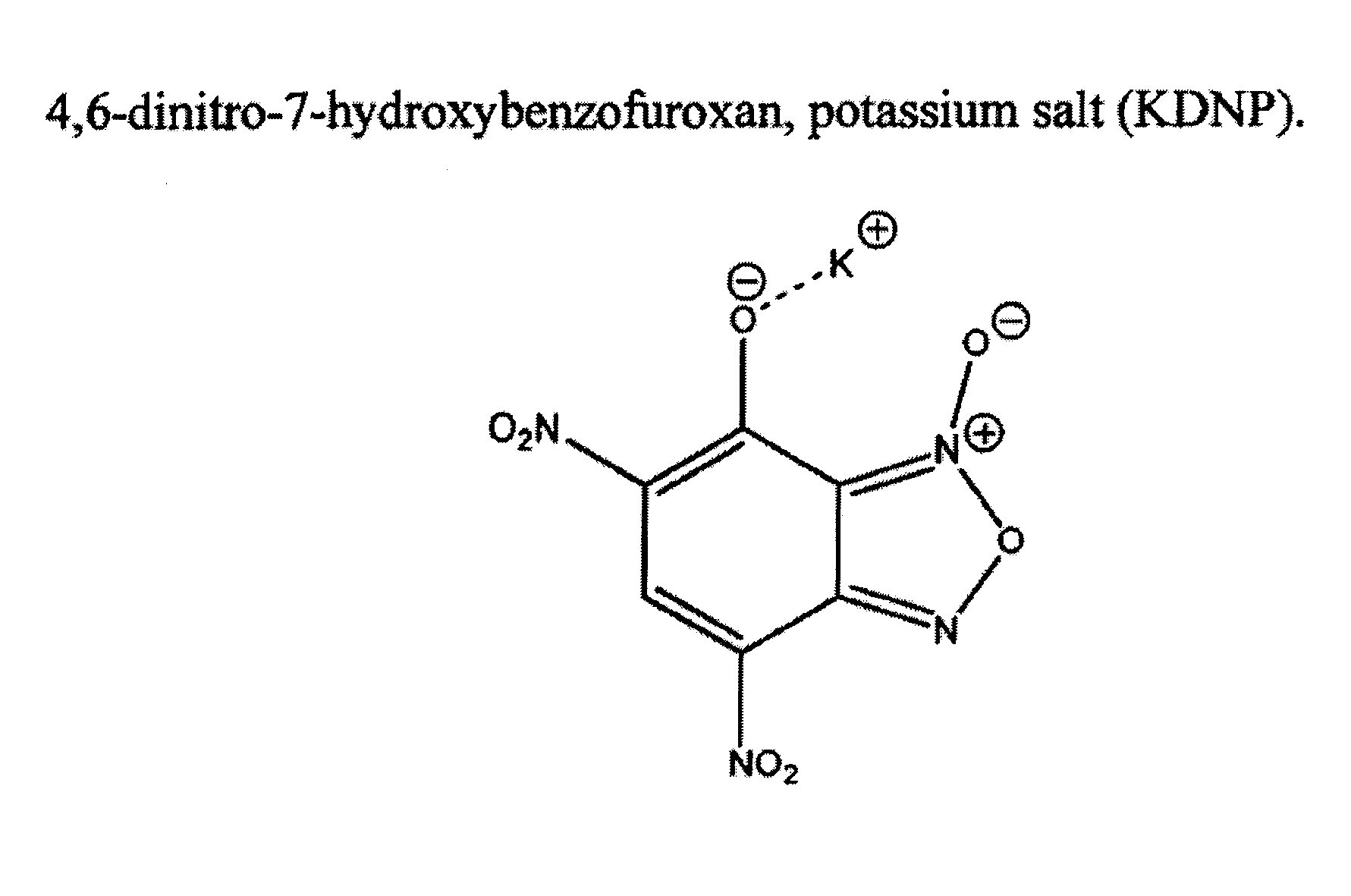

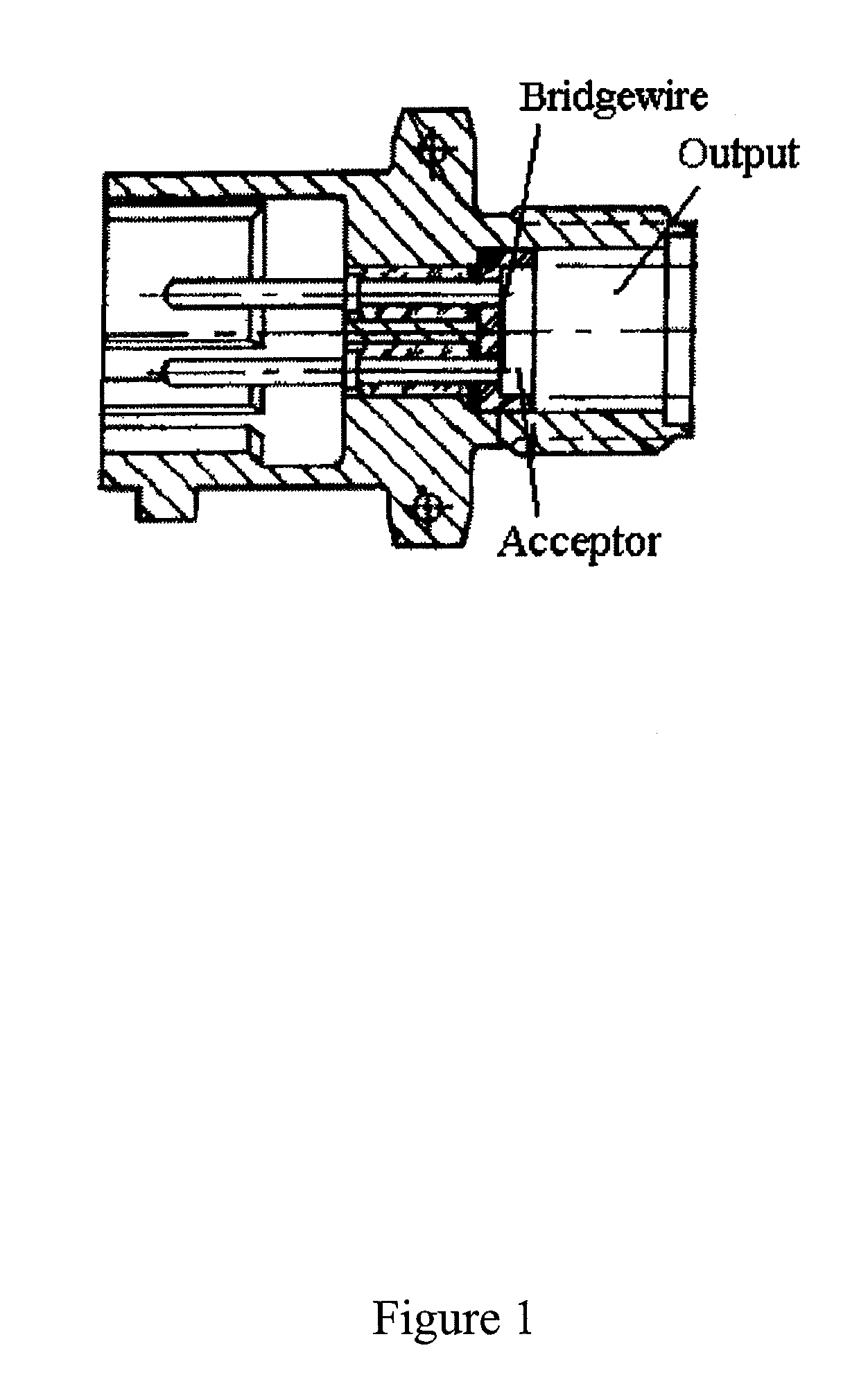

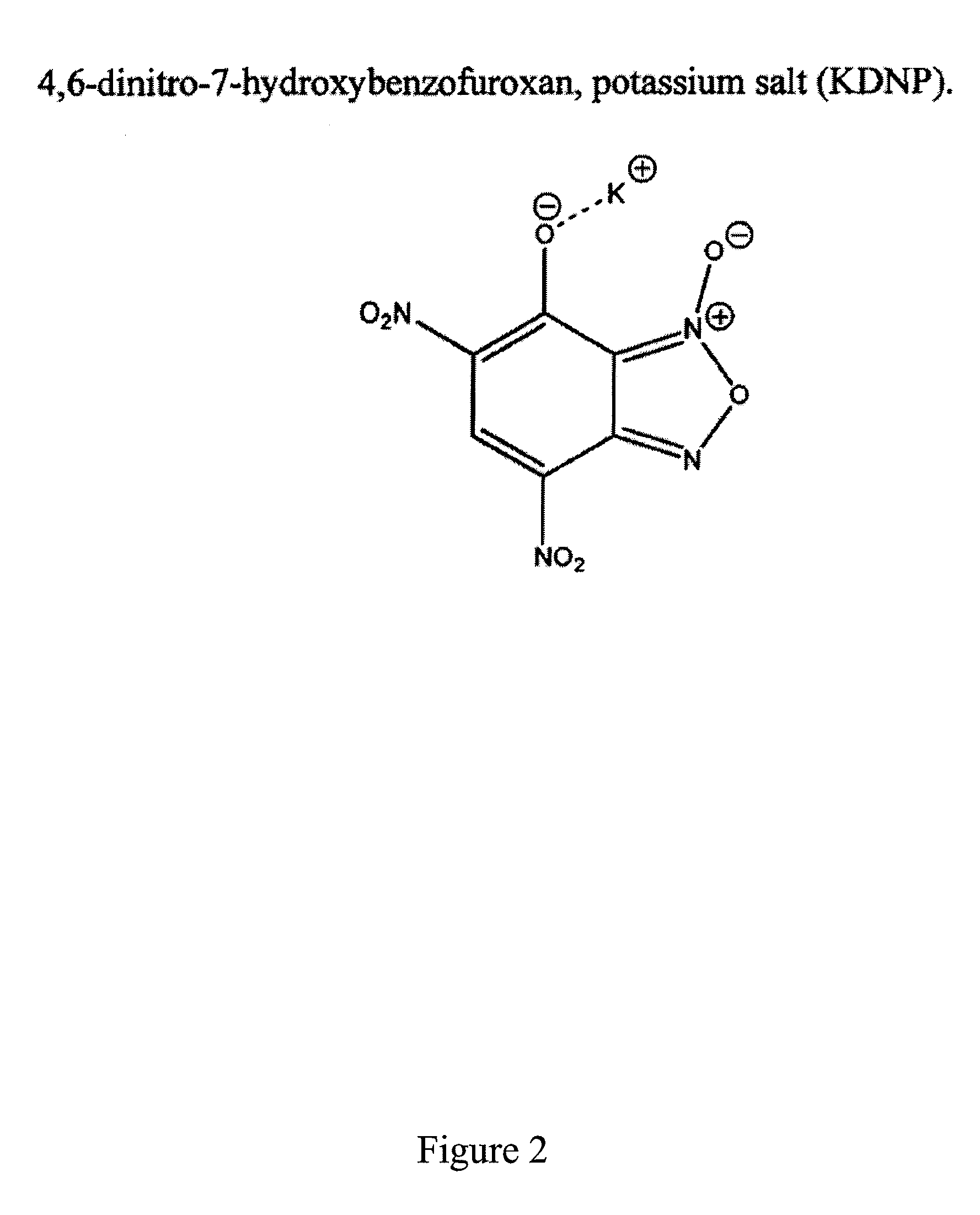

Embodiments of the present subject matter provide an improved percussion primer composition and improved hot-wire igniter acceptor, wherein lead styphnate is replaced with a lead-free material, 4,6-dinitro-7-hydroxybenzofuroxan, potassium salt (KDNP). Embodiments of the percussion primer composition include KDNP, a sensitizer, an oxidizer, calcium silicide, a fuel, and a binder. Sensitizers may include tetracene. Oxidizers may include alkali or alkaline earth nitrates, oxides, or peroxides (such as barium nitrate). Fuel materials may include metals, metal sulfides, or other non-metallic materials. Common binders may include nitrocellulose based shellacs, gum arabic / poly vinyl alcohol mixtures, and guar gum / poly vinyl alcohol mixtures. Embodiments of the hot-wire igniter device include a bridgewire, an acceptor, and an output, where KDNP is the acceptor. Power supply may be in the form of constant current / voltage or current flow from a capacitor discharge. Certain embodiments utilize a variety of output formulations, such as BKNO3, black powder, and Red Dot double base propellant.

Owner:PACIFIC SCI ENERGETIC MATERIALS +1

Lead-free primers

Embodiments of the present subject matter provide an improved percussion primer composition and improved hot-wire igniter acceptor, wherein lead styphnate is replaced with a lead-free material, 4,6-dinitro-7-hydroxybenzofuroxan, potassium salt (KDNP). Embodiments of the percussion primer composition include KDNP, a sensitizer, an oxidizer, calcium silicide, a fuel, and a binder. Sensitizers may include tetracene. Oxidizers may include alkali or alkaline earth nitrates, oxides, or peroxides (such as barium nitrate). Fuel materials may include metals, metal sulfides, or other non-metallic materials. Common binders may include nitrocellulose based shellacs, gum arabic / poly vinyl alcohol mixtures, and guar gum / poly vinyl alcohol mixtures. Embodiments of the hot-wire igniter device include a bridgewire, an acceptor, and an output, where KDNP is the acceptor. Power supply may be in the form of constant current / voltage or current flow from a capacitor discharge. Certain embodiments utilize a variety of output formulations, such as BKNO3, black powder, and Red Dot double base propellant.

Owner:PACIFIC SCI ENERGETIC MATERIALS +1

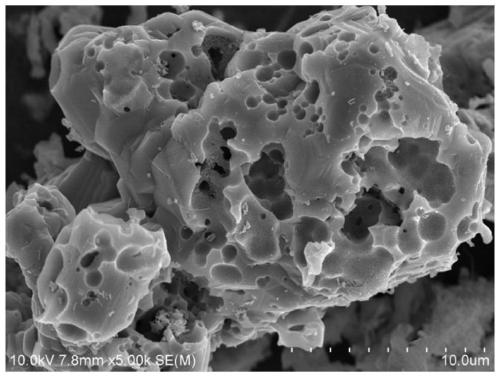

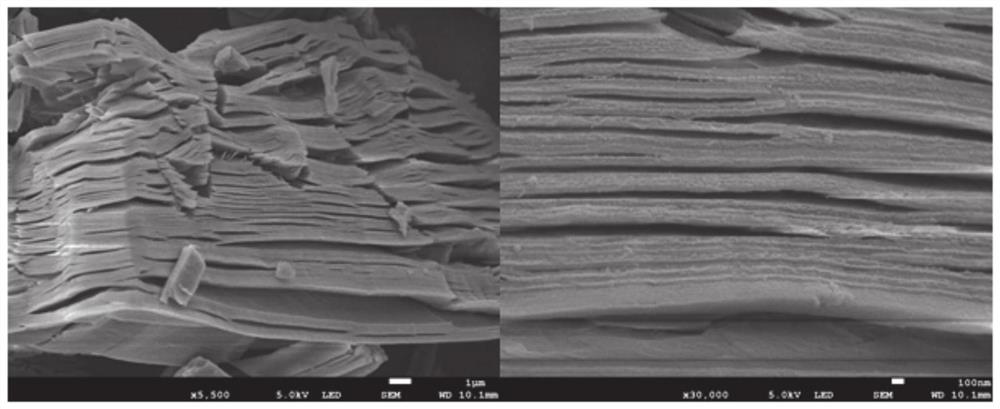

Preparation method of porous silicon

InactiveCN109763134ARegulatory formCheap and easy to getElectrolysis componentsSurface treatment compositionsElectrolysisReaction temperature

The invention relates to a preparation method of porous silicon, and belongs to the technical field of material preparation. The method comprises the steps as follows: performing pressing formation onsilicon dioxide powder for preparation of blocks, and performing sintering forming to obtain a porous electrode; wrapping and pressing the porous electrode by a porous conductive material to serve asa cathode, or winding and binding the porous electrode by a metal wire to serve as a cathode, and performing electrolysis with molten salt containing calcium chloride as an electrolyte and graphite as an anode; washing an electrolytic product with a hydrochloric acid solution and treating the product with a hydrofluoric acid solution to obtain a porous silicon material. Continuous electrolysis can be realized by replacing the cathode, and the morphology and composition ratio of silicon / calcium silicide electrolysis products can be controlled by controlling molten salt temperature, electrolysis process parameters, electrolysis electric quantity and the like, so that the morphology of porous silicon can be conveniently regulated and controlled; recycling of calcium chloride can be realized;the method has the advantages that raw materials are cheap and easily available, reaction temperature is relatively low, the morphology of porous silicon is easy to adjust, production can be enlargedconveniently and the like.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

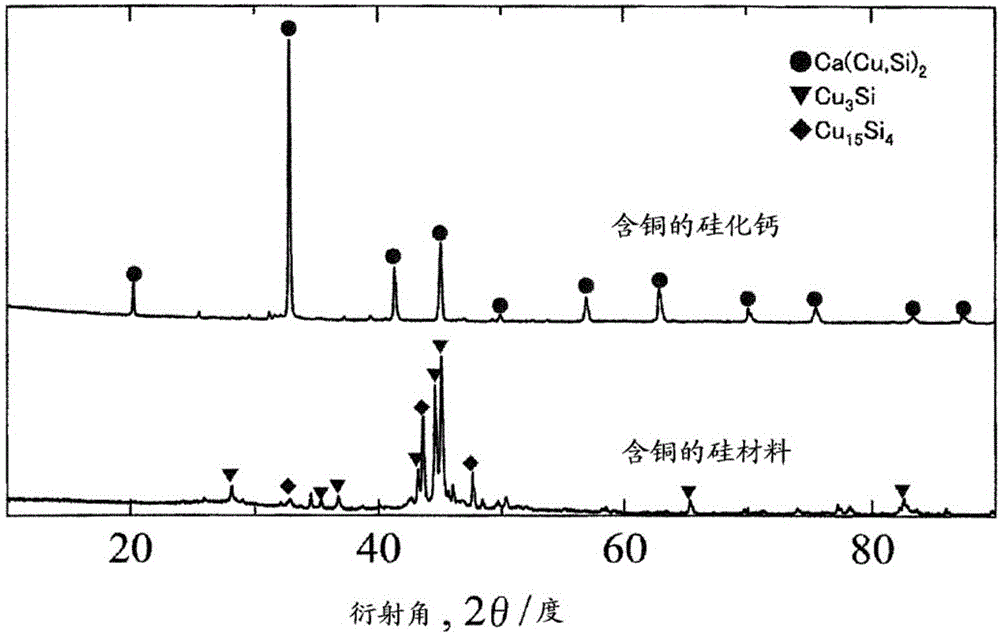

Copper-containing silicon material, method for manufacturing same, negative-electrode active substance, and secondary cell

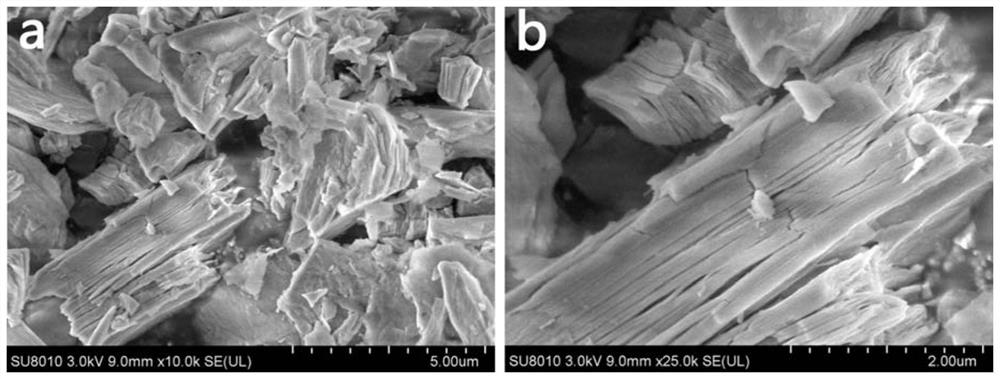

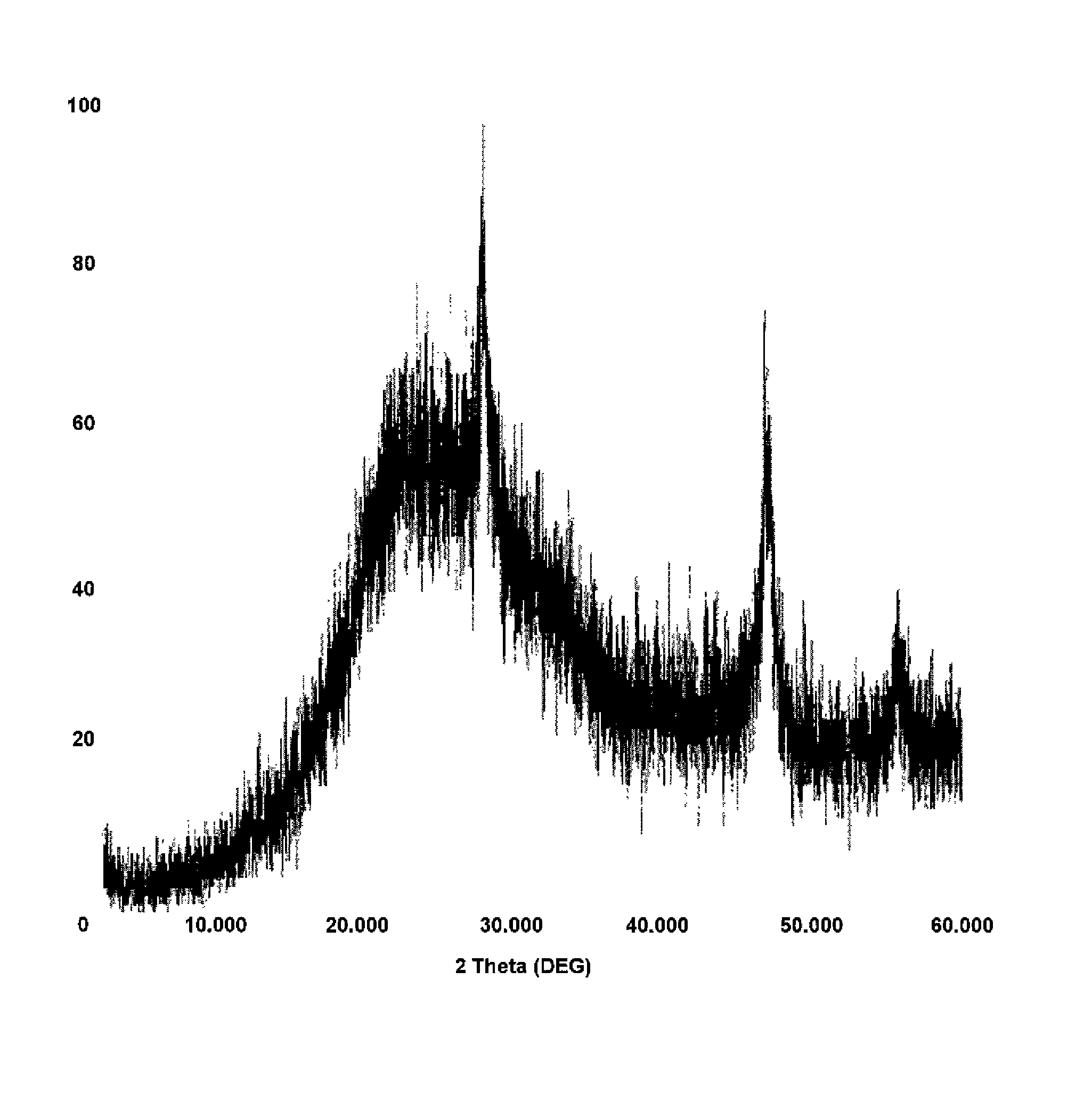

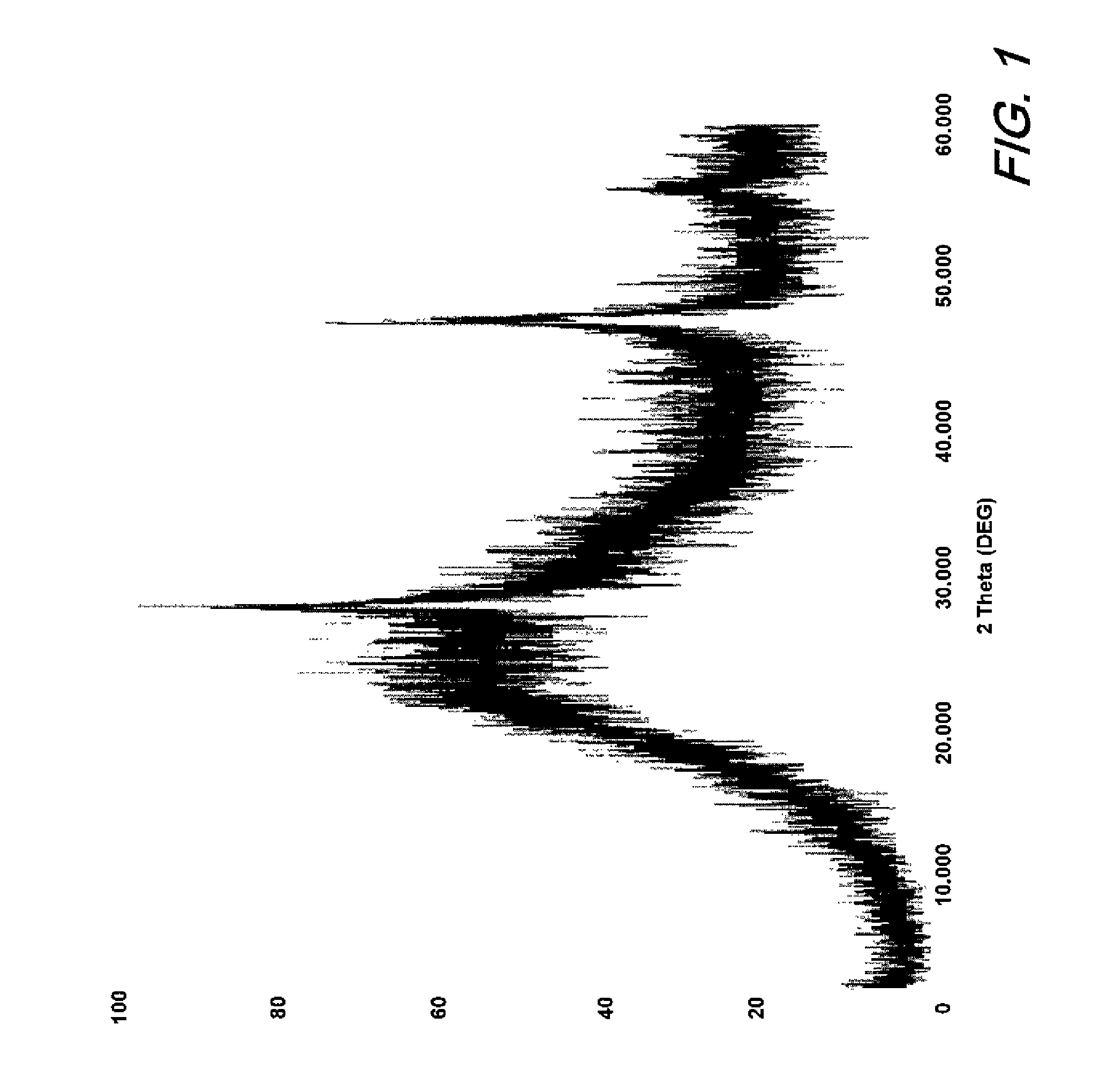

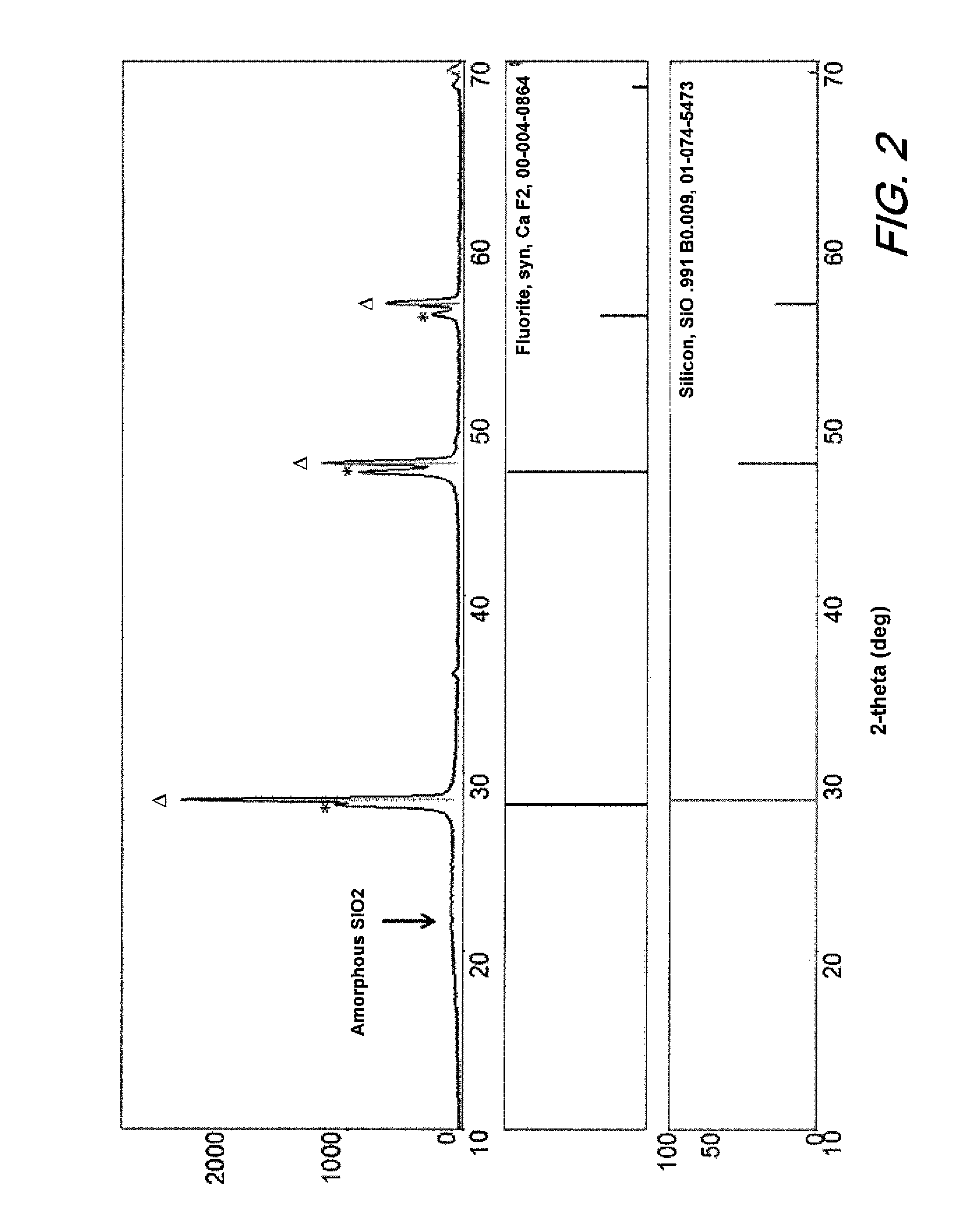

InactiveCN106458610AImprove electronic conductivityHybrid capacitor electrodesCell electrodesElectrical batteryAmorphous phase

Provided is a negative-electrode active substance having enhanced electron conductivity. In the present invention, a copper-containing silicon material is obtained by reacting copper-containing calcium silicide represented by the formula CaCuxSiy with oxygen and heat-treating the reaction product in a non-oxidizing atmosphere. The copper-containing silicon material includes Si and copper in an amorphous phase, and fine copper silicides are uniformly deposited in the amorphous phase, and the copper-containing silicon material therefore has enhanced electron conductivity. A secondary cell which uses the negative-electrode active substance in a negative electrode thereof therefore has enhanced lead characteristics and increased charge / discharge capacity.

Owner:TOYOTA IND CORP

Calcium deoxidizer using dolomite as refractory component and preparation method thereof

The invention discloses a calcium deoxidizer using dolomite as the refractory component. The calcium deoxidizer is characterized in that it is prepared from the following raw materials by weight part: 32-36 of calcium silicide, 10-13 of silicon carbide, 4-6 of photovoltaic cell processing waste sand, 40-48 of 5% hydrochloric acid, 3.5-4.5 of carboxymethylcellulose sodium, 2-3 of water glass, 3-4 of dolomite, and 1-2 of manganese dioxide. The calcium deoxidizer provided by the invention adopts calcium silicide, calcium carbide and the like as the main ingredients, dolomite is added as the high temperature resistant component, and through a series of processes, a porous component can be prepared, thus accelerating the efficiency of reaction with oxygen, reducing solid Al2O3 cluster inclusions, enhancing the molten steel fluidity. Therefore, the deoxidation effect is enhanced, and the alloy element recovery rate is improved. The calcium deoxidizer is feasible in production, and can achieve good economic benefits.

Owner:芜湖华炀炉料科技有限公司

Calcium deoxidizer using nano graphite powder as carrier and preparation method thereof

The invention discloses a calcium deoxidizer using nano graphite powder as a carrier. The invention is characterized in that the calcium deoxidizer is prepared from the following raw materials in parts by weight: 32-35 parts of calcium silicide, 14-20 parts of silicon carbide, 1.5-2.5 parts of anthracite duff, 2.5-4 parts of nano graphite powder, 40-50 parts of 5% hydrochloric acid and 3-5 parts of polyvinyl alcohol. In order to solve the problems in the prior art, the formula and technique are modified. By adopting the calcium silicide and other components, the calcium deoxidizer has favorable deoxidizing and desulfurizing effects, and has favorable carburization effect when being used for producing straight carbon steel, low-alloy steel and other types of medium-carbon steel. The added nano graphite powder can improve the flowability of the molten steel, effectively removes inclusions in the steel, enhances the purity of the molten steel and prevents tundish nozzle blocking. The technique is convenient for industrial control, has favorable deoxidizing effect, and can enhance the recovery rate of the alloy elements.

Owner:芜湖华炀炉料科技有限公司

Composite material for automobile parts

The invention discloses a composite material for automobile parts. The composite material is composed of, by weight, 92-95% of aluminum, 0.05-0.07% of actinium, 0.2-0.3% of manganese, 2-2.5% of iron, 0.1-0.2% of boron, 0.2-0.25% of carbon, 1.5-2% of molybdenum disulfide, 0.3-0.35% of magnesium, 0.05-0.1% of hexadecyl trimethyl ammonium bromide, 4-5% of oxidized graphene, 6-10% of zirconium hydride, 0.5-1% of hexachloroethane, 0.35-0.55% of calcium silicide, 0.8-1% of montmorillonoid, 0.2-0.4% of Arabic gum, 0.3-0.5% of magnesium oxide, 2-2.5% of activated aluminum oxide, 0-0.01% of impurities and an appropriate amount of deionized water. Aluminum products made of the composite material have the advantages that the strength, the hardness and the high-temperature heat stability are high. In addition, raw materials are easy to obtain, the processing cost is low, the preparation technology is simple, parameters are easy to control, the production process is safe and friendly to environment, and therefore the composite material is suitable for large-scale industrial production.

Owner:CHONGQING SHUAIBANG MACHINERY CO LTD

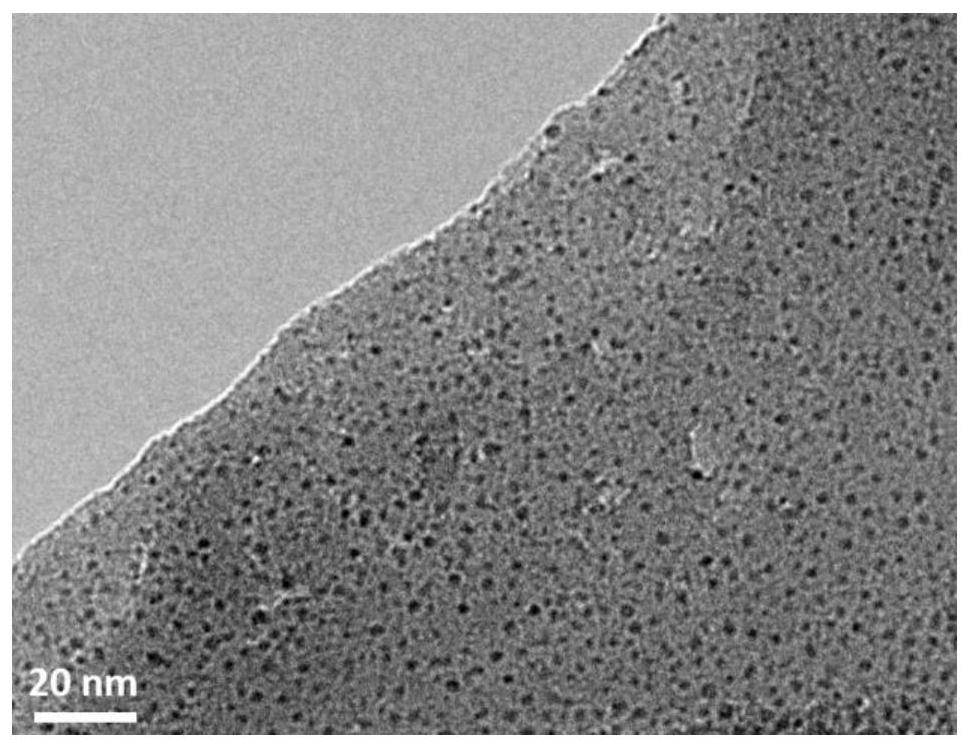

Method for preparing two-dimensional ultrathin silicon wafer loaded silver nanoparticles

InactiveCN110480027AImprove conductivityAvoid formingTransportation and packagingMetal-working apparatusOrganic solventLithium-ion battery

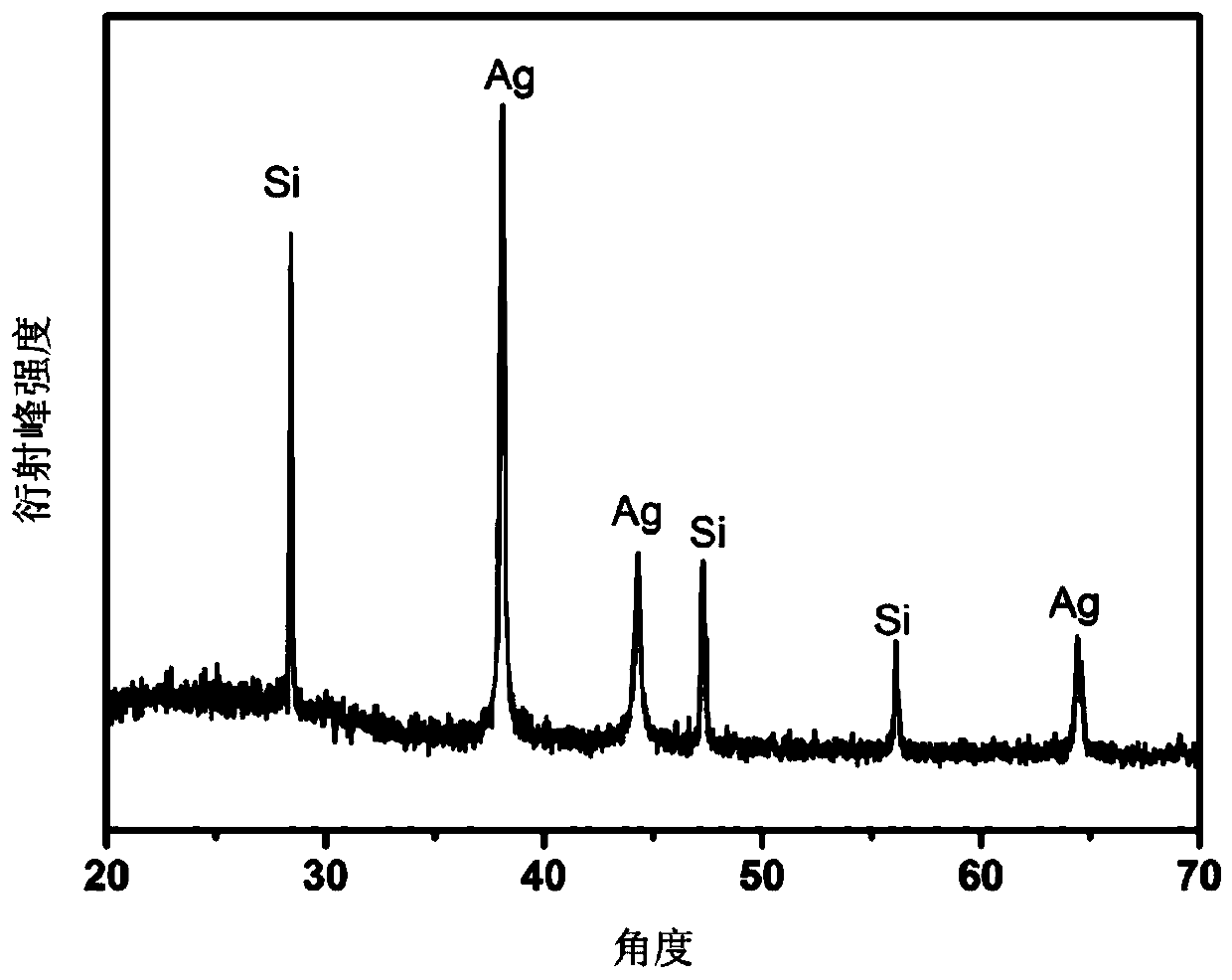

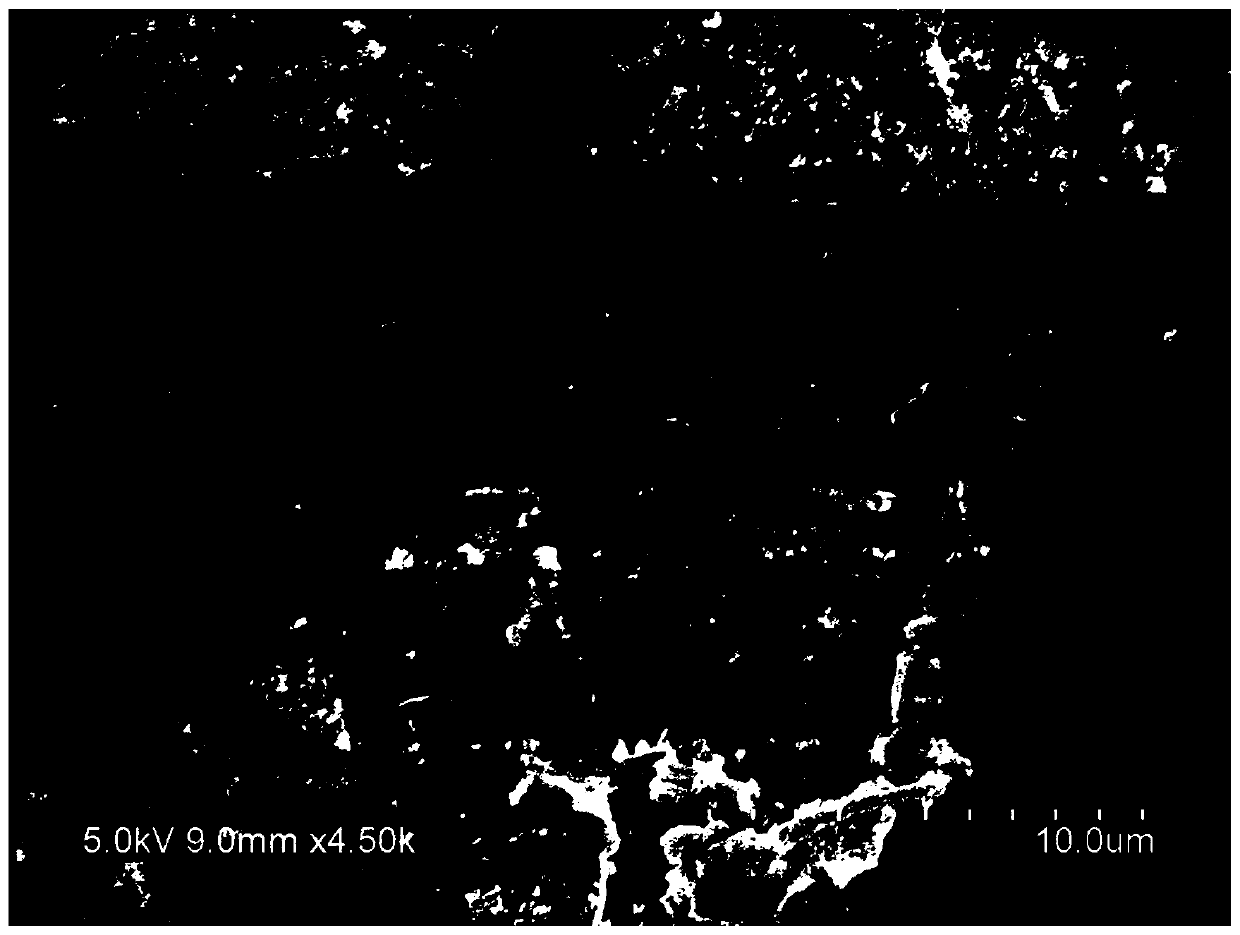

The invention discloses a method for preparing two-dimensional ultrathin silicon wafer loaded silver nanoparticles. The method includes the following steps that firstly, calcium silicide is put into concentrated hydrochloric acid to be reacted, filtered and washed, vacuum drying is conducted, and a Si6H6 nano sheet is obtained; secondly, silver nitrate is dissolved into amine which can form a complexing effect with Ag+, and a silver nitrate amine solution is prepared; and thirdly, the Si6H6 nano sheet is ultrasonically dispersed in an organic solvent and is added to the silver nitrate amine solution, reacting, filtering and washing are conducted, and a two-dimensional ultrathin silicon wafer loaded silver nanoparticle composite material is obtained. By means of the method, the concentratedhydrochloric acid and the layered compound calcium silicide are reacted to generate the Si6H6 nano sheet, then the Si6H6 nano sheet is added to a silver nitrate and amine complex compound, and the two-dimensional ultrathin silicon wafer loaded silver nanoparticle composite material is obtained through a one-step reaction. The steps are simple, operation is easy, and the obtained composite material has potential application in the field of high-magnification lithium ion batteries.

Owner:YANCHENG INST OF TECH

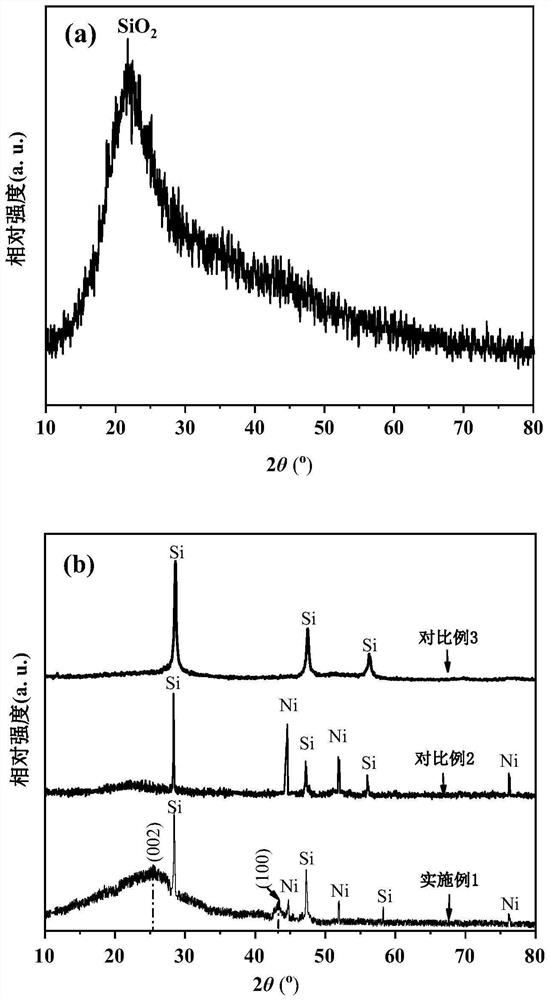

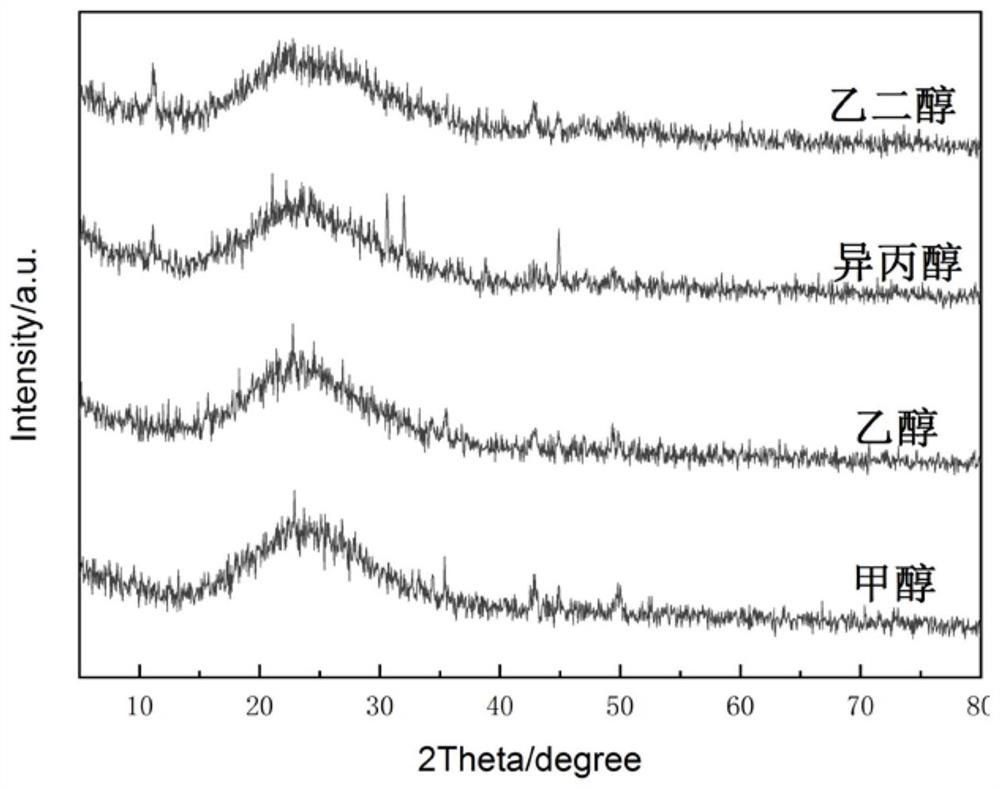

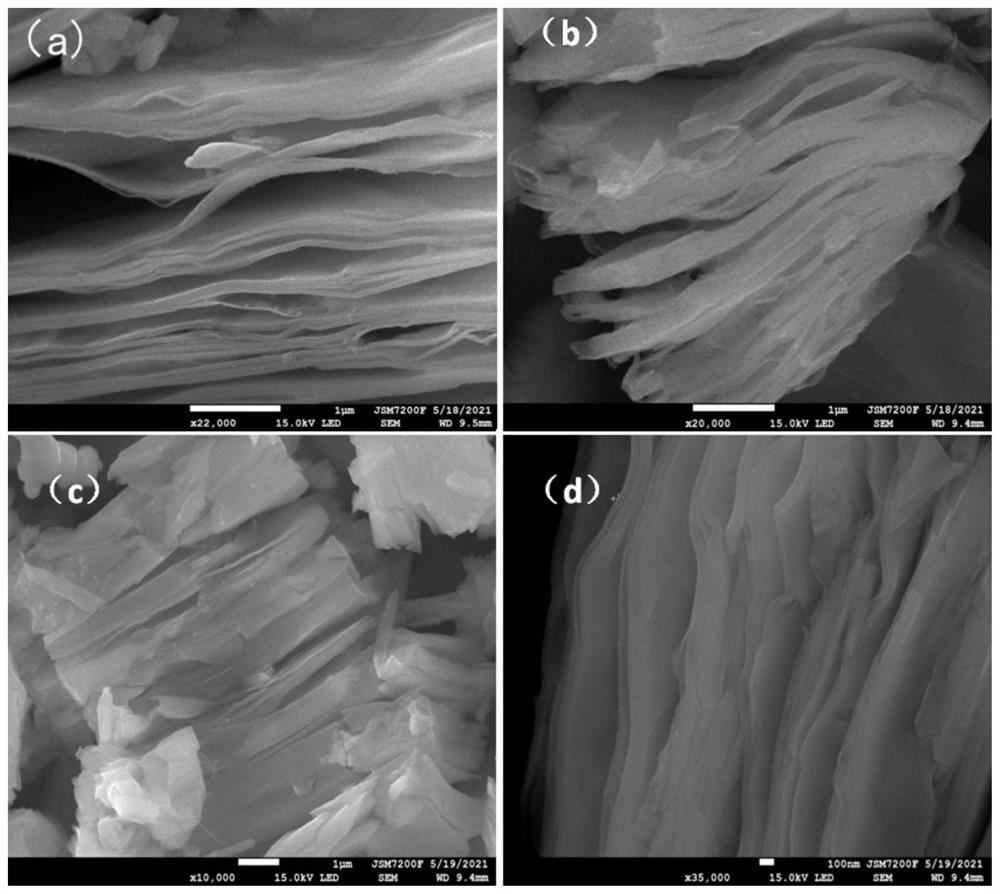

Two-dimensional silicon dioxide as well as preparation method and application thereof

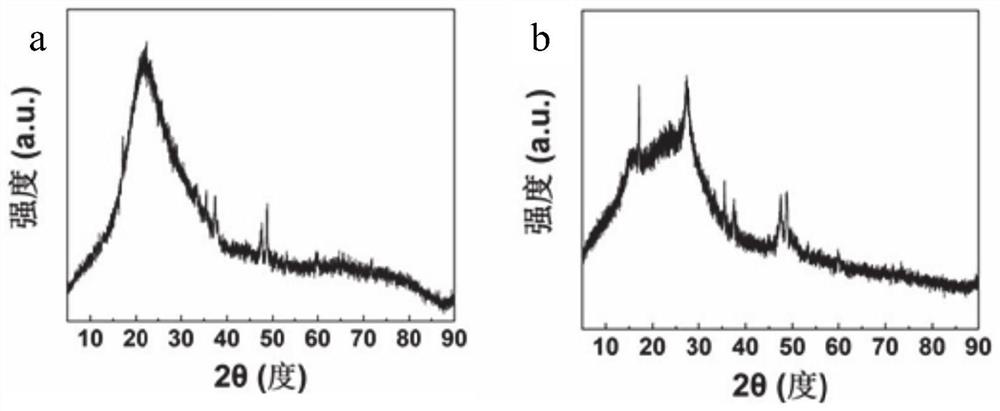

PendingCN113488376ALow costFewer steps in the preparation processMaterial nanotechnologySemiconductor/solid-state device manufacturingAir atmosphereHeat stability

The invention belongs to the technical field of materials, and particularly relates to two-dimensional silicon dioxide as well as a preparation method and application thereof. The method comprises the following steps of acidizing a calcium silicide alloy to obtain siloxene, and carrying out heat treatment on the siloxene in an air atmosphere to prepare the two-dimensional silicon dioxide. According to the method, the two-dimensional silicon dioxide is obtained through acid treatment and heat treatment in the air atmosphere by adopting a commercial precursor, an expensive template agent is not needed in the whole preparation process, the precursor is also a commercially available material, the whole preparation process is few in step and simple in process, and large-scale and low-cost preparation of the two-dimensional silicon dioxide can be realized. The two-dimensional silicon dioxide prepared by the invention not only can be used as a negative electrode material in a lithium battery, shows excellent cycling stability, but also can be used for preparing a diaphragm with high thermal stability.

Owner:山东大学深圳研究院

Calcium deoxidizer able to optimize molten steel viscosity and preparation method thereof

The invention discloses a calcium deoxidizer able to optimize molten steel viscosity. The calcium deoxidizer is characterized by being prepared from the following raw materials by weight part: 34-37 of calcium silicide, 13-18 of silicon carbide, 5-7 of barium carbonate, 42-50 of 5% acetic acid, 3.5-5 of pregelatinized starch, 2-3 of montmorillonite, and 1.5-2 of lignin. The process involved in the invention is scientific and reasonable, the calcium deoxidizer is made into porous particles, is easy to form negative pressure, and can fully react with oxygen in molten steel. By adding montmorillonite, the calcium deoxidizer has good dispersibility, improves the viscosity of molten steel, thereby improving molten steel fluidity, effectively removing inclusions in steel, enhancing molten steel purity, and preventing tundish nozzle clogging. The steel made by the calcium deoxidizer provided by the invention has mechanical properties like yield strength and tensile strength increased by certain extent, the calcium deoxidizer is feasible in production, and can achieve good economic benefits.

Owner:芜湖华炀炉料科技有限公司

Low-alloy cast steel used for automobile axle housing and long in service life

The invention discloses low-alloy cast steel used for an automobile axle housing and long in service life. The low-alloy cast steel is prepared from, by weight, 95-98 parts of waste steel (the iron content is not smaller than 98%), 2-3 parts of Z18 pig iron, 0.4-0.45 part of crystal silicon, 0.18-0.2 part of carbon, 1.4-1.5 part of manganese, 0.28-0.3 part of nickel, 0.08-0.1 part of vanadium, 0.1-0.12 part of titanium, 0.8-0.86 part of calcium silicide, 0.2-0.24 part of polyurethane emulsion, 0.5-0.54 part of bauxite, 0.35-0.4 part of titanium white and not larger than 0.01 part of impurities. The low-alloy cast steel is scientific and reasonable in component matching, waste steel is adopted, raw material cost is saved, the prepared low-alloy cast steel is durable, the technical problems that the compressive capacity of the middle of an automobile axle housing in the prior art is low, and the service life is short are solved, and the low-alloy cast steel is an ideal automobile axle housing material.

Owner:ANHUI YUEZHONG AUTO BODY EQUIP

Dry-spray powder products for the protection of moulds for the centrifugal casting of iron pipes, in association with a wet-spray powder product

InactiveCN101160186AGood adhesionImprove effectivenessFoundry mouldsFoundry coresAlloySilicon dioxide

Owner:PECHINEY ELECTROMETALLURGIE

Cast steel material with added rare earth elements for automobile axle

InactiveCN105986166AAchieve compositeImprove liquidityProcess efficiency improvementRare-earth elementSlag

The invention discloses a cast steel material with added rare earth elements for an automobile axle. The cast steel material is prepared from, by weight, 95-98 parts of waste steel (the content of iron is not smaller than 98%), 2-3 parts of Z18 pig iron, 0.4-0.45 part of crystalline silicon, 0.3-0.35 part of carbon, 0.02-0.024 part of scandium, 0.03-0.04 part of yttrium, 1.5-1.7 parts of manganese, 2-2.3 parts of chromium, 0.03-0.04 part of antimony, 0.8-0.86 part of calcium silicide, 0.3-0.34 part of yellow phosphorus slag, 0.6-0.7 part of nano-graphite powder, 0.43-0.48 part of a hot melt adhesive and smaller than or equal to 0.01 part of impurities. By means of the cast steel material, due to the fact that the rare earth elements such as scandium and yttrium are used, grains can be refined, the material organization can be more compact, and wear resistance of the material is improved; and due to scientific and reasonable matching design and producing and processing technologies, the prepared cast steel material has the good comprehensive performance, and the cast steel material is very suitable for producing an automobile axle part.

Owner:ANHUI YUEZHONG AUTO BODY EQUIP

Corrosion-resistant cast steel material for automobile parts

The invention discloses a corrosion-resistant cast steel material for auto parts, which is made of the following raw materials in parts by weight: steel scrap (iron content not less than 98%) 95-98, Z18 pig iron 2-3, crystalline silicon 0.7-0.75, Carbon 0.3-0.35, niobium 0.04-0.05, titanium 0.4-0.5, manganese 1.2-1.3, chromium 0.04-0.05, calcium silicide 0.8-0.86, gelatin 0.2-0.23, lime powder 0.2-0.24, calcium fluoride 0.3-0.4, heavy Crystal 0.5-0.55, impurity ≤ 0.01. The invention can improve the intergranular corrosion and improve the corrosion resistance of the cast steel material by rationally configuring the ratio of element components and the production process, and adding elements such as titanium and niobium; The auto parts produced are corrosion-resistant, low-temperature resistant, and have a long service life.

Owner:ANHUI YUEZHONG AUTO BODY EQUIP

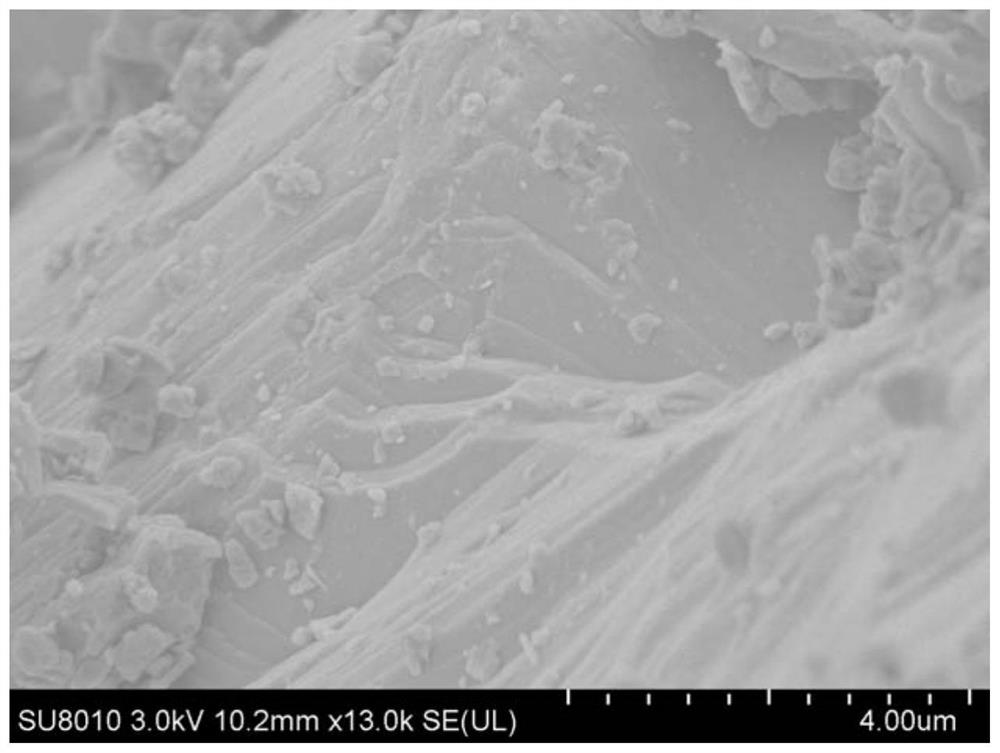

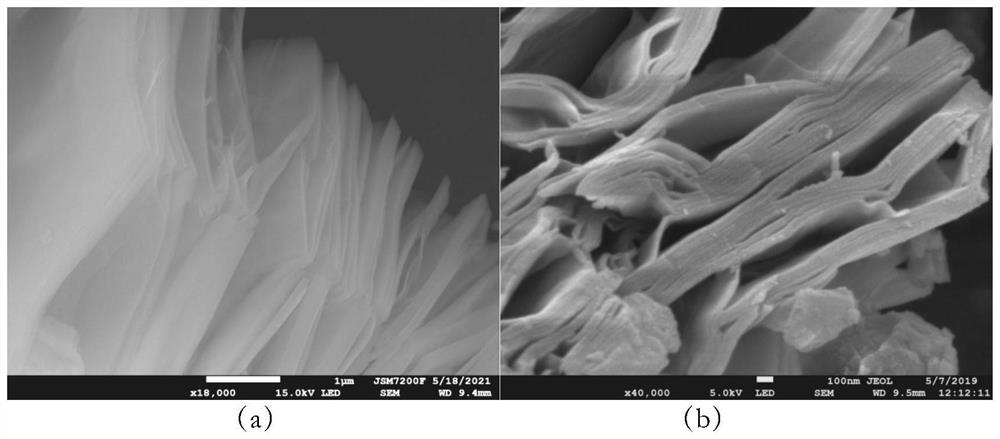

Oxygen-containing silicon nanosheet supported noble metal catalyst as well as preparation method and application thereof

InactiveCN113258085AHigh dispersion growthIncrease profitCell electrodesFuel cellsPtru catalystActive agent

The invention discloses an oxygen-containing silicon nanosheet (SiOx NSs) supported noble metal catalyst as well as a preparation method and application thereof. The unique group of SiOx NSs is utilized to realize high-dispersion loading of noble metal on the surface of SiOx NSs, and the problem that active sites are masked due to the use of a reducing agent or a surfactant in a traditional liquid-phase synthesis method is avoided. The preparation method comprises the following steps of firstly, adding calcium silicide into concentrated hydrochloric acid for etching, so that calcium ions are deintercalated to form oxygen-containing silicon nanosheets with Si-H and Si-OH groups and a layered structure, and uniformly dispersing SiOx NSs in a noble metal inorganic compound aqueous solution, and carrying out a hydrothermal reaction to obtain the noble metal / oxygen-containing silicon nanosheet composite material. The SiOx NSs supported noble metal catalyst prepared by the invention has excellent electrocatalytic activity and stability on methanol oxidation reaction and hydrogen evolution reaction, and has a good application prospect in the technical field of sustainable energy conversion. The invention provides a universal preparation strategy of a novel noble metal catalyst, the synthesis process is simple, and the utilization rate of noble metal is improved.

Owner:HUNAN UNIV

Calcium deoxidizer for improving molten steel fluidity and preparation method thereof

The invention discloses a calcium deoxidizer for improving molten steel fluidity. The calcium deoxidizer is characterized in that it is prepared from the following raw materials by weight part: 34-38 of calcium silicide, 12-16 of silicon carbide, 2.5-3.5 of flow guiding sand, 2-3 of coke powder, 3.5-5 of gelatin, and 40-50 of 5% hydrochloric acid. The method provided by the invention adopts a special technology to prepare the main component into particles and then conducts sintering to form a porous structure, thus being conducive to forming negative pressure in the molten steel and increasing the rate of reaction with oxygen. The main component is calcium silicide, at a steelmaking temperature, the steam pressure is very high, additionally, part of the deoxidation product is gas CO, the molten steel can be stirred strongly, thereby improving the molten steel fluidity, effectively removing impurities in molten steel, enhancing the molten steel purity, and preventing tundish nozzle clogging. The calcium deoxidizer is feasible in production, and can achieve good economic benefits.

Owner:芜湖县天海耐火炉料有限公司

Calcium deoxidier with good purification effect on molten steel and preparation method thereof

The invention discloses a calcium deoxidier with a good purification effect on molten steel. The calcium deoxidier is characterized by being prepared from the following raw materials by weight part: 35-37 of calcium silicide, 12-17 of silicon carbide, 1-2 of xanthan gum, 2-3 of industrial starch, 3-4 of black manganese ore, 40-50 of 5% hydrochloric acid, and 2.5-3.5 of AD powder. Compared with the prior art, the calcium deoxidier provided by the invention has reasonable component proportion, does not contain aluminum element, is added with black manganese ore crushed into 200 meshes, and is prepared into particles together with calcium silicide, silicon carbide and the like, and then the particles are sintered and pickled to form porous particles. The calcium deoxidier not only can effectively react with oxygen in molten steel, but also can react with sulfur in molten steel at the same time to achieve the molten steel purification effect, and improve the steel quality and alloy element recovery rate. The process is convenient for industrial control, is feasible in production, and can achieve good economic benefits.

Owner:芜湖县天海耐火炉料有限公司

Casting steel capable of being used for producing mining truck axle housing

InactiveCN105463332AAchieve compositeImprove liquidityProcess efficiency improvementAxle unitsCrack resistanceManganese

The invention discloses casting steel capable of being used for producing a mining truck axle housing. The casting steel is prepared from, by weight, 95-98 parts of waste steel (the iron content is not smaller than 98%), 2-3 parts of Z18 pig iron, 0.4-0.45 part of crystal silicon, 0.3-0.34 part of carbon, 0.2-0.24 part of cerium, 0.4-0.5 part of calcium, 0.9-1.1 parts of manganese, 1.2-1.3 parts of chromium, 0.05-0.06 part of molybdenum, 0.8-0.86 part of calcium silicide, 0.1-0.12 part of a silica solution, 0.2-0.25 part of industrial starch, 0.5-0.6 part of barium sulfate, 0.3-0.35 part of waste glass and not larger than 0.01 part of impurities. According to the casting steel capable of being used for producing the mining truck axle housing, cerium, calcium and other elements are added in the steel casting process, the fluidity and the heat crack performance of the casting steel are improved due to addition of a mixed de-oxidizing agent, the machining performance is improved, the product subjected to heat treatment is high in strength, plasticity and heat crack resistance, and requirements of various mining truck axle housings are met.

Owner:ANHUI YUEZHONG AUTO BODY EQUIP

Graphite-doped tough and self-lubricating automobile part cast steel material

InactiveCN105986165AAchieve compositeImprove liquidityElectric furnaceProcess efficiency improvementFiberManganese

The invention discloses a graphite-doped touch and self-lubricating automobile part cast steel material. The cast steel material is prepared from, by weight, 95-98 parts of waste steel (the content of iron is not smaller than 98%), 2-3 parts of Z18 pig iron, 0.4-0.45 part of crystalline silicon, 4-4.5 parts of graphite, 0.5-0.6 part of selenium , 0.1-0.12 part of tungsten, 1.7-2 part of manganese, 1.4-1.6 parts of chromium, 0.8-0.86 part of calcium silicide , 0.8-0.9 part of fiber pulp, 0.7-0.75 part of electroslag premelted slag, 0.3-0.33 part of fluorite powder and smaller than or equal to 0.01 part of impurities. By means of the cast steel material, the components such as graphite and selenium are added in the casting and smelting process so that lubricating systems can be formed in the cast steel material; due to the fact that a composite deoxidizing agent is added, the lubricating systems are evenly distributed in a base body; and the cast steel material has the beneficial effects of being good in antifriction performance, not likely to be abraded, high in strength, good in toughness, wide in application range and the like and is very suitable for being manufactured into various automobile parts, abrasion is not likely to happen because of lubrication, and the service life is prolonged.

Owner:ANHUI YUEZHONG AUTO BODY EQUIP

Calcium deoxidizer with calcium silicide as main component and preparation method thereof

The invention discloses a calcium deoxidizer with calcium silicide as the main component. The calcium deoxidizer is characterized by being prepared from the following raw materials by weight part: 33-38 of calcium silicide, 10-12 of calcareous shale, 14-18 of silicon carbide, 3-4.5 of polyvinylpyrrolidone, 2-3 of silica sand, 42-50 of 10% acetic acid, and 3-4 of carbon fiber. The calcium deoxidizer provided by the invention has reasonable composition proportion, the process is special and is convenient for industrial control, calcium silicide, silicon carbide, silica sand and the like are prepared into particles, the particles are then sintered into porous particles, thus being conducive to forming negative pressure, fully reacting with oxygen in molten steel, and improving the deoxidization efficiency. Specifically, the silica sand is crushed into small particle powder to improve dispersibility in molten steel, thereby enhancing molten steel fluidity, effectively removing inclusions in steel, improving molten steel purity, and preventing tundish nozzle clogging.

Owner:芜湖华炀炉料科技有限公司

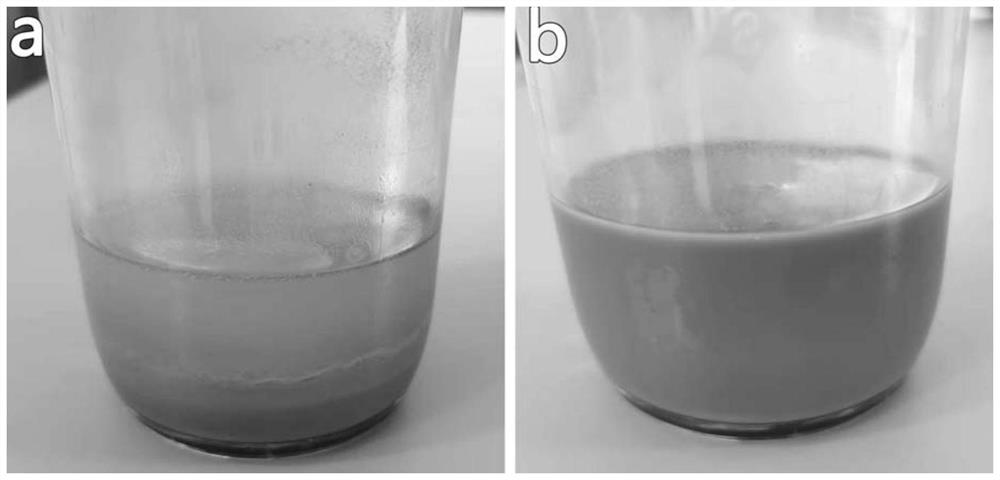

Sulfonic acid group functionalized siloxy alkene for zinc-based flow battery and preparation method of sulfonic acid group functionalized siloxy alkene

ActiveCN114684824ALift InductionLift anchor Zn <sup>2+<</sup> Cell electrodesRegenerative fuel cellsSilyleneOverpotential

The invention discloses sulfonic acid group functionalized silylene for a zinc-based flow battery and a preparation method of the sulfonic acid group functionalized silylene, and belongs to the technical field of preparation of battery electrode materials. The preparation method comprises the following steps: efficiently stripping a silicide raw material calcium silicide in a topological chemical solvent of monobasic or polybasic acid and an oxidizing agent through a topological chemical method to obtain the siloxyalkene nanosheet, and further performing sulfonic acid group functional modification on the siloxyalkene nanosheet by using a sulfonic acid grafting agent to obtain the high-quality sulfonated siloxyalkene nanosheet. The zinc-based flow battery negative electrode coated with the sulfated siloxy alkene can effectively solve the problems of zinc dendrite growth, accumulation and the like, stable and uniform low-overpotential zinc deposition / stripping is realized, and the development of further commercial application of the zinc-based flow battery is promoted.

Owner:浙江大学温州研究院 +1

Remediation of fluorine and chlorine by-products in energetic formulations

InactiveUS8480825B1Loss of measurable energetic effectAvoid undesirable formationLoomsWoven fabricsIn situ remediationDetonation

A method of in-situ remediation of chlorinated and fluorinated reaction by-products resulting from energetic detonations and / or burning of energetic mixtures comprising adding a quantity of Calcium disilicide (CaSi2), Calcium silicide (CaSi), Magnesium disilicide (MgSi2), Magnesium silicide, or Aluminum Calcium (Al2Ca) compounds to the energetic mixture prior to its detonation and / or burning. Advantageously, the in-situ production of more inert by-products results from this addition thereby preventing the formation of any less-desirable by-products.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Calcium deoxidizer beneficial to industrial production and preparation method thereof

The invention discloses a calcium deoxidizer beneficial to industrial production. The calcium deoxidizer is characterized by being prepared from the following raw materials by weight part: 35-38 of calcium silicide, 2-3 of charcoal, 12-15 of silicon carbide, 3-5 of fly ash, 2-3 of calcite, 40-50 of 5% hydrochloric acid, and 4-5 of hydroxypropyl methyl cellulose. The calcium deoxidizer provided by the invention has scientific and reasonable proportion, and the process is convenient for industrial control and saves energy. During use of the calcium deoxidier, the alloy composition is stable and has small fluctuation, no air hole is found in a casting blank, during continuous casting ladle sampling, the molten steel in a mode is calm and does not rise, and the deoxidation effect is good. At the same time, the calcium deoxidizer can improve molten steel fluidity, effectively remove inclusions in steel, improve molten steel purity, and prevent tundish nozzle clogging, is feasible in production, and can achieve good economic benefits.

Owner:芜湖华炀炉料科技有限公司

High-strength lathe tool manufacturing technique

A high-strength lathe tool manufacturing technique includes the following steps: 1) after a steel material is melted, epoxy resin and calcium silicide are added into the molten steel; 2) the molten steel is poured into a mould and is pressed into a plate material, and then quenching treatment is performed; 3) potassium permanganate erosion is performed after the quenching treatment; and 4) air cooling is performed to change the molten material. The obtained high-strength lathe tool is high in strength and excellent in abrasive resistance.

Owner:XIAN FURST POWER TECH

High-strength lathe tool

The invention provides a high-strength lathe tool. The high-strength lathe tool comprises, by mass ratio, 30%-45% of steel, 20%-25% of epoxy resin, 20%-25% of calcium silicide and 15%-20% of potassium permanganate. Fused materials are changed. The high-strength lathe tool has the advantages of being high in strength and abrasion resistance.

Owner:XIAN FURST POWER TECH

Glaze for enameled cup opening part

The invention relates to the technical field of glaze, in particular to glaze for an enameled cup opening part. The glaze is prepared from, by weight, 12-16 parts of bauxite, 24-32 parts of red soil, 12-18 parts of Shaanxi soil, 2-3 parts of spodumene, 2-3 parts of gallium nitride, 2-3 parts of ox bones, 4-6 parts of vanadium pentoxide, 3-7 parts of aluminum phosphate, 3-7 parts of calcium oxide, 3-7 parts of calcium silicide, 5-10 parts of a stabilizing additive and 5-10 parts of modified zeolite. The glaze is large in surface tension, resistant to abrasion after being dried, non-volatile at the high temperature, free of toxic and side effects, allows direct contact with the human body and is especially suitable for the enameled cup opening part.

Owner:ANHUI QINGHUAFANG FINE BONE PORCELAIN

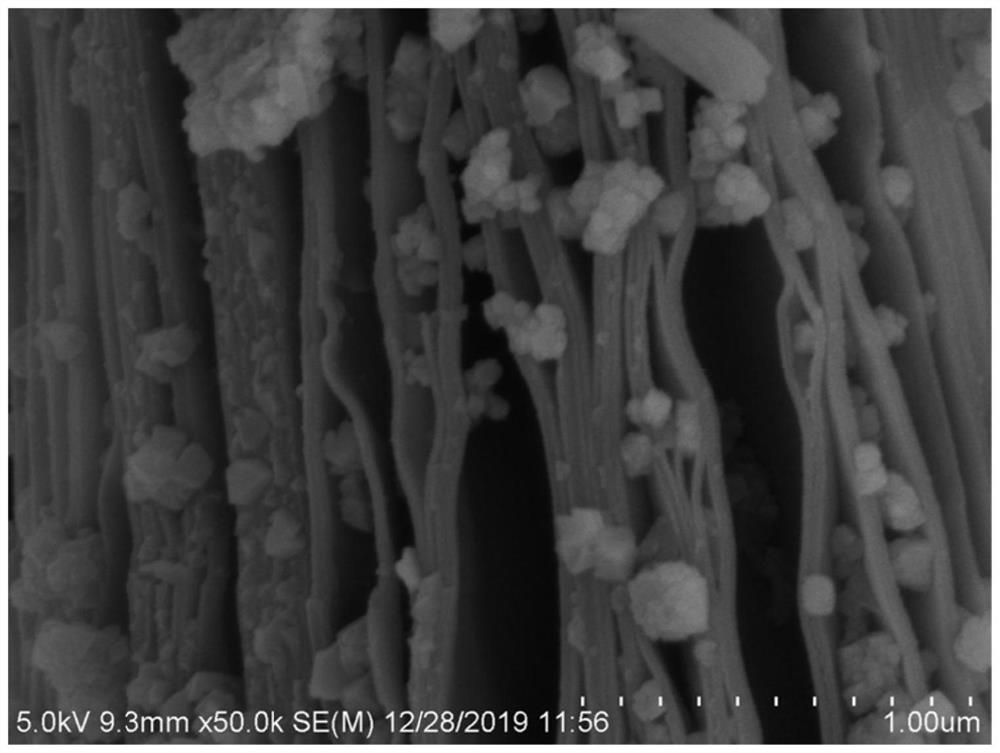

Graphite-coated metal particle-containing silicon nanosheet fast-charging negative electrode material, method and battery

The invention discloses a graphite-coated metal particle-containing silicon nanosheet fast-charging negative electrode material, a method and a battery. The preparation method comprises the following steps: mixing calcium silicide and a reducing agent in an anhydrous metal chloride solution to form slurry, and fully reacting the slurry under a stirring condition to obtain a precipitate A; cleaning the precipitate A, and freeze-drying to obtain a metal particle-containing silicon nanosheet; and sequentially carrying out chemical vapor deposition and heat treatment on the metal particle-containing silicon nanosheet to obtain the graphite-coated metal particle-containing silicon nanosheet fast-charging negative electrode material. The process is simple, the silicon nanosheet can be prepared without strict anaerobic conditions, and the method is suitable for industrial production. The lithium ion battery prepared from the material has the advantages of good quick charge performance, high stability, excellent rate capability and the like.

Owner:海宁硅泰科技有限公司

Calcium composite end deoxidizer for steelmaking and preparation method thereof

The invention discloses a calcium composite end deoxidizer for steelmaking. The deoxidizer is characterized by being prepared from the following raw materials by weight part: 34-40 of calcium silicide, 4-5 of bamboo charcoal, 13-18 of silicon carbide, 40-50 of 5% sulfuric acid, 4-5 of Sesbania gum, 3-5 of nano-graphite powder, and 3-4 of nano-titanium dioxide. The calcium composite end deoxidizer provided by the invention does not contain aluminum element, and has reasonable composition proportion. calcium silicide, calcium carbide, bamboo charcoal, nano-graphite powder and the like are added to prepare particles, then the particles are sintered and then pickled to form porous particles, so that calcium element can be effectively dissolved in molten steel and effectively react with oxygen in molten steel at the same time, the nozzle clogging phenomenon can be improved, the molten steel fluidity is improved, thereby improving the deoxidation effect. With low cost, the calcium composite end deoxidizer is feasible in production, and can achieve good economic benefits.

Owner:芜湖县天海耐火炉料有限公司

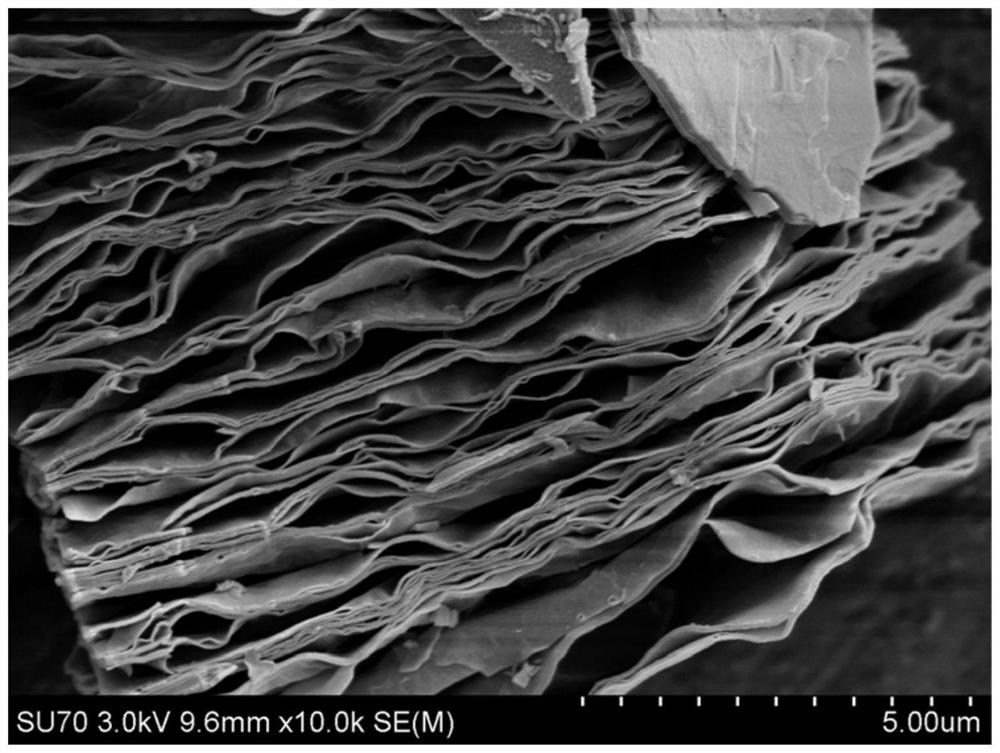

Method for preparing two-dimensional layered silicon nanosheet material based on topological chemical method

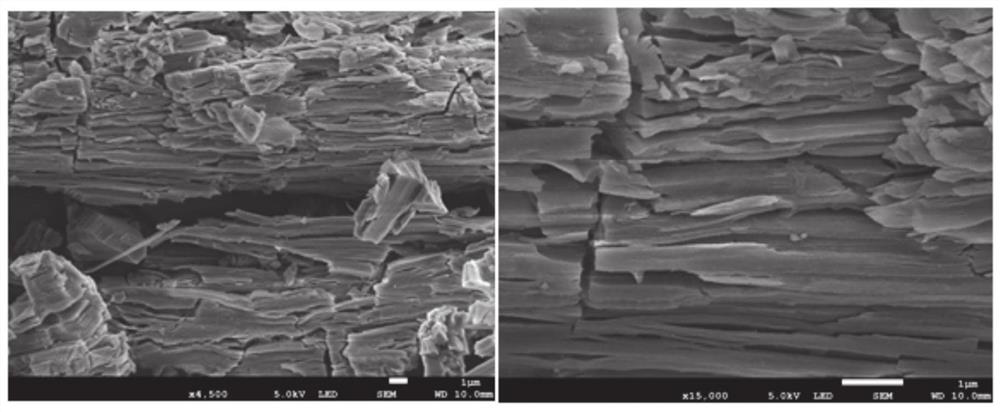

PendingCN114105146AType adjustableLarge specific surface areaMaterial nanotechnologySilicon compoundsPhysical chemistryNitrogen gas

The invention discloses a method for preparing a two-dimensional layered silicon nanosheet material based on a topological chemical method. According to the method, a topological chemical method is adopted, the tin ions enter the interior of a calcium silicide structure, so that the calcium ions are replaced, then the tin ions are washed away through a mixed solution of hydrochloric acid and an oxidizing agent with different concentrations, and a mutually separated silicon lamellar structure is formed, so that the silicon nanosheet material is obtained. The method has the advantages of mild reaction conditions, short reaction time, no need of nitrogen protection, simple required equipment and convenient operation, is beneficial to large-scale preparation of the two-dimensional layered silicon nanosheet material, and can be used for large-scale industrial production. The silicon nanosheet material prepared by the method has the advantages that a large number of active sites and surface functional groups are reserved, the types of the surface functional groups are adjustable, the specific surface area is increased, the sheet layer is thin and the like.

Owner:TAIYUAN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com