Graphite-coated metal particle-containing silicon nanosheet fast-charging negative electrode material, method and battery

A metal particle, silicon nanosheet technology, applied in metal material coating process, nanotechnology, nanotechnology and other directions, can solve the problems of volume expansion, easy crushing, unstable material interface, etc., to maintain integrity, simple process, The effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

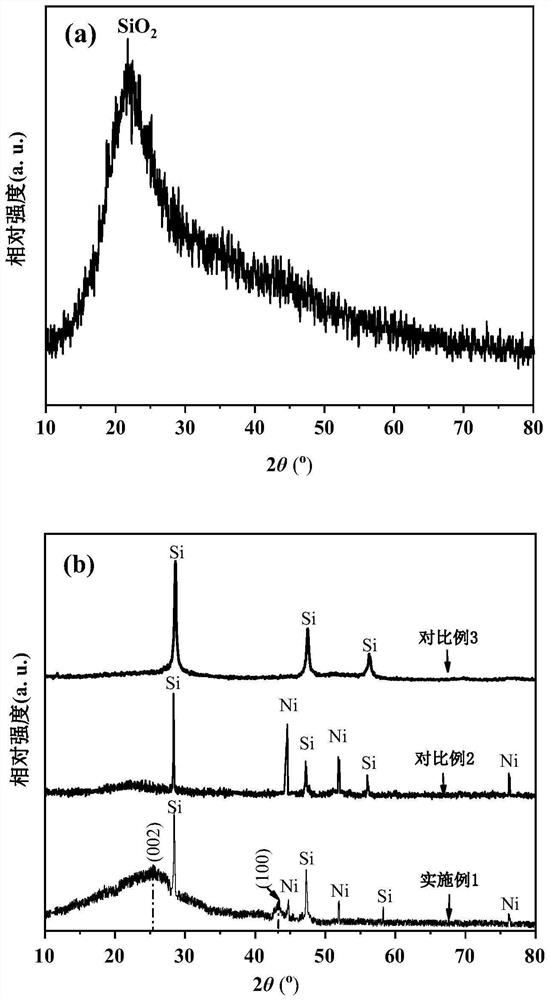

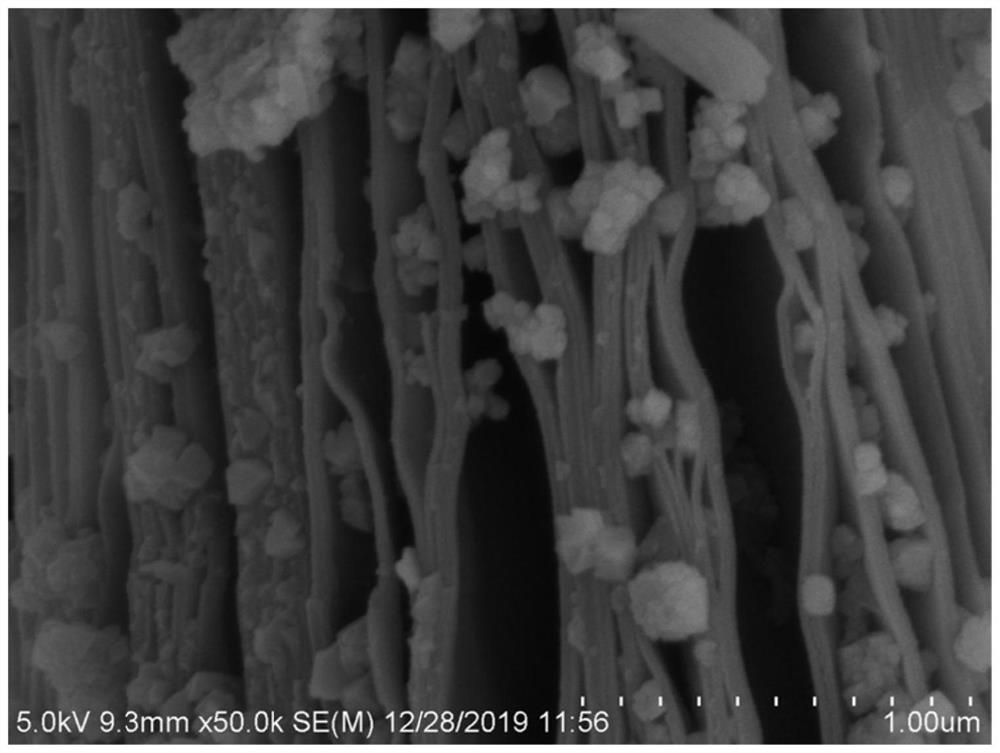

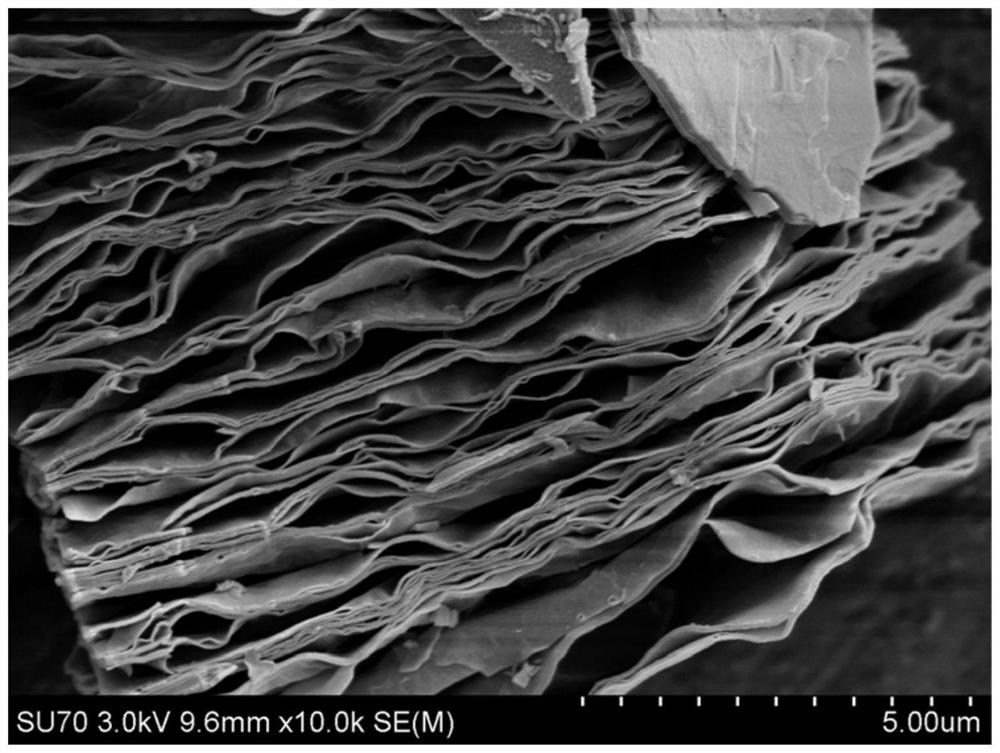

Embodiment 1

[0030] Dissolve 10g of anhydrous nickel chloride in 100ml of ethanol, weigh 1g of CaSi 2 , 2g ascorbic acid and 1g sodium borohydride. Put all the raw materials into the reactor and react at 80°C without pressure for 5h. Next, the pressure of the reactor was set to 20 MPa, and the temperature was set to 200° C., and the reaction was continued for 1 hour under these conditions to obtain a precipitate A. The precipitate A was washed several times with ethanol and then freeze-dried at -60°C to obtain nickel-containing silicon nanosheets. The nickel-containing silicon nanosheets were heat-treated at 700°C for 1 hour under the protection of argon, followed by acetylene gas for 20 minutes, and then heated to 950°C for 2 hours under the protection of argon to obtain graphite-coated nickel-containing silicon nanosheets for fast charging.

Embodiment 2

[0032] Dissolve 10g of anhydrous cobalt chloride in 100ml of ethanol, weigh 1g of CaSi 2 and 2 g sodium borohydride. Put all the raw materials into the reactor and react at 15MPa and 40°C for 2h. Next, the pressure of the reactor was set to 40 MPa, and the temperature was set to 150° C., and the reaction was continued for 0.5 h under these conditions to obtain silicon nanosheets. The silicon nanosheets were washed several times with ethanol and then freeze-dried at -80°C to obtain cobalt-containing silicon nanosheets. Cobalt-containing silicon nanosheets were heat-treated at 650°C for 1.5 hours under the protection of argon, followed by acetylene gas for 15 minutes, and then heated to 950°C for 2 hours under the protection of argon to obtain graphite-coated cobalt-containing silicon nanosheets for fast charging. Material.

Embodiment 3

[0034] Dissolve 5g of anhydrous nickel chloride and 5g of anhydrous cobalt chloride in 100ml of ethanol, weigh 1g of CaSi 2 and 2 g sodium borohydride. Put all the raw materials into the reactor and react at 80°C without pressure for 5h. Next, the pressure of the reactor was set to 20 MPa, and the temperature was set to 200° C., and the reaction was continued for 1 hour under these conditions to obtain a precipitate A. Precipitate A was washed several times with ethanol and then freeze-dried at -80°C to obtain silicon nanosheets containing nickel and cobalt. Silicon nanosheets containing nickel and cobalt were heat-treated at 750°C for 2 hours under the protection of argon, followed by methane gas for 30 minutes, and then heated to 1000°C for 3 hours under the protection of argon to obtain graphite-coated silicon nanosheets containing nickel and cobalt Fast charge negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com